Thin Film Anti-Foul Exchanger Coatings

Curran applies advanced coatings to eliminate fouling of heat exchangers in crude production and refining operations. Using precise application methods these thin film coatings are highly functional, deliver anti-foul performance to optimize performance of critical exchangers.

The Curran low surface energy coating portfolio includes Teflon™, silicone and ceramic coatings, which are applied onto carbon steel and alloy exchangers at 15-50 microns. Applications have achieved surface tension lower than 30 dynes/cm2 which enhance release performance at the substrate.

Installed exchangers show extended run times without shutdown for routine maintenance cleaning and leading to increased production. The reduced tube fouling contributes to unit energy savings and GHG credits.

Curran is the world leader in heat exchanger coating; refinery, petrochemical and power generation clients have used tube coating to solve cooling water scaling and deposit failure for more than 25 years. All applications are subject to Curran quality control, and critical hold points documented and reported to client. Curran coats and restores in-service exchangers, applies protective coating to tube ends and tube sheets, mobilizes for expert in-situ and field coating applications.

Engineered thin film foul release exchanger coatings

Curran 1000 – Single coat application of silicone formulation, maximizing release performance in a thin film; for all cooling water services; applications at 3-4 mils total DFT, tubesheets coated to 20 mils.

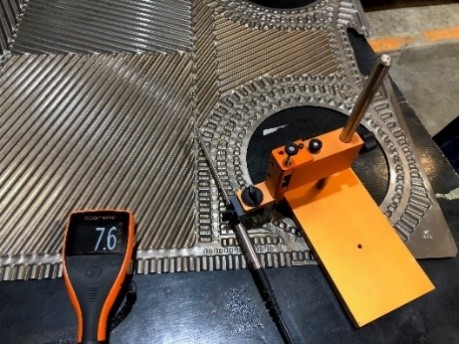

Curramix 3500 – Advanced, ultra-thin anti-fouling hybrid or inorganic ceramic coating for crude or hydrocarbon fouling; excellent hydrophobic & oleophobic properties, inorganic formulation functional to 750°F. Applied 12-40 micron total DFT, used for heat exchanger tubes, plate & frame exchangers.

Chemours StreaMax™ – Non-stick release fluoropolymer with excellent adhesion to applied surfaces and high permeation resistance. The very low friction coefficient prevents fouling of exchangers in oil production and crude refining.

PFA – Shop applied, bake catalyzed fluoropolymers; superior resistance in chemicals, solvents and acids. Immersion resistant to 500°F. Applied to 4 - 7 mils DFT.

Danish Technological Institute (DTI) – Low surface energy hydrophobic coating, applied at 5 – 40 microns film thickness; Curran applied to tubular, and plate & frame exchangers in crude derived services, produced water services.

Sol Gel Coatings - Polymer surface treatment; omniphobic (water and oil repellant) nanocomposite surface treatment that creates slick surface. Applied to 50 microns; water and product services to 400F.

Contact Curran to discuss its foul release coatings and thin film applications to improve exchanger efficiency.

SEO Services by Essential Information Technologies

Copyright © Curran International All rights reserved.