Curran International’s epoxy coating solutions for HVAC chillers are engineered to protect tubesheets, waterboxes, and channels from corrosion in immersion service. These high-performance coatings create a smooth, durable barrier that reduces fouling, maintains efficiency, and withstands routine cleaning. Applied with precision, they extend chiller service life and ensure reliable operation across institutional and commercial facilities.

Chiller/HVAC tubesheet coating can provide a solution to your cooling water corrosion problems. Typical problems arise at the tube to tubesheet interface, often as a result of dissimilar metals and galvanic attack. For years Curran International has provided technicians and epoxy coating systems to repair and protect mild steel tubesheets from corrosion attacks.

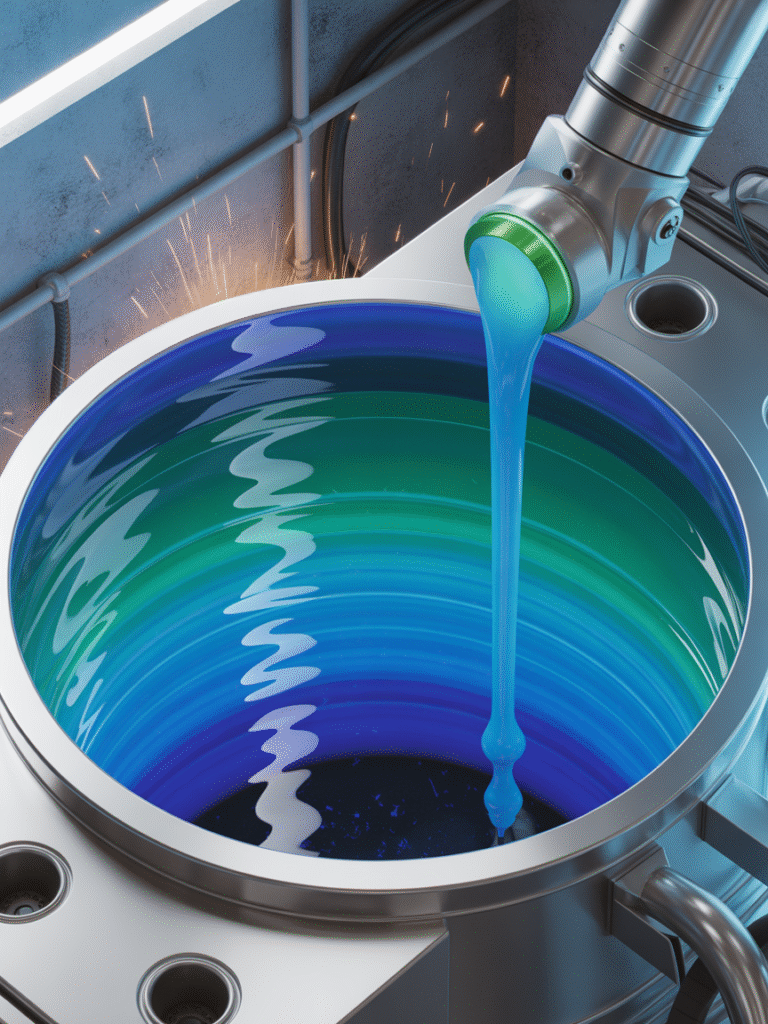

Curran 500 is an advanced two part 100% solids epoxy (0 VOCs) with versatile formulations to satisfy a range of application specifications.

It can be used as a brush or roller applied liquid film, encapsulating corroded substrate with a homogeneous protective film.

Applied at an average of 50 mils DFT and the use of tube forming plugs enhances the inlet flow of cooling water while giving tubesheets years of reliable service.

The Curran 500 system has been used for all cooling water services to protect chiller tube sheets, water boxes, marine boxes, channels and circulation piping.

Provides superior protection in all water services, ensuring long-lasting performance in submerged conditions.

Excellent foul release properties with reduction in drag, improving system efficiency.

Excellent performance against cathodic disbondment, preventing coating failure in electrochemical environments.

Curran provides turnkey applications, and our site containment methods meets expectations of building maintenance protocols at institutional, office building, educational, governmental and medical institutions. Curran coatings have been used for major OEM chiller restorations from 300 to 2500 tons units.

Specialized containment methods for office buildings and institutional settings.

Clean application processes suitable for sensitive healthcare environments.

Meeting strict protocols for governmental building maintenance requirements.

Safe application methods appropriate for school and campus environments.

Evaluation of tubesheet condition and determination of appropriate coating specifications.

Thorough cleaning and preparation of the substrate to ensure proper adhesion.

Professional application of Curran 500 epoxy system using specialized techniques.

Final inspection to ensure complete coverage and proper curing of the coating.

Complete application kits available for shipment from Houston.

Professional application services with site containment dust vacuum system.

Curran has a branded product program for HVAC maintenance companies and industrial applicators. Contact Curran for a coating material quote.

Please enter your name and email. We’ll be in touch soon.