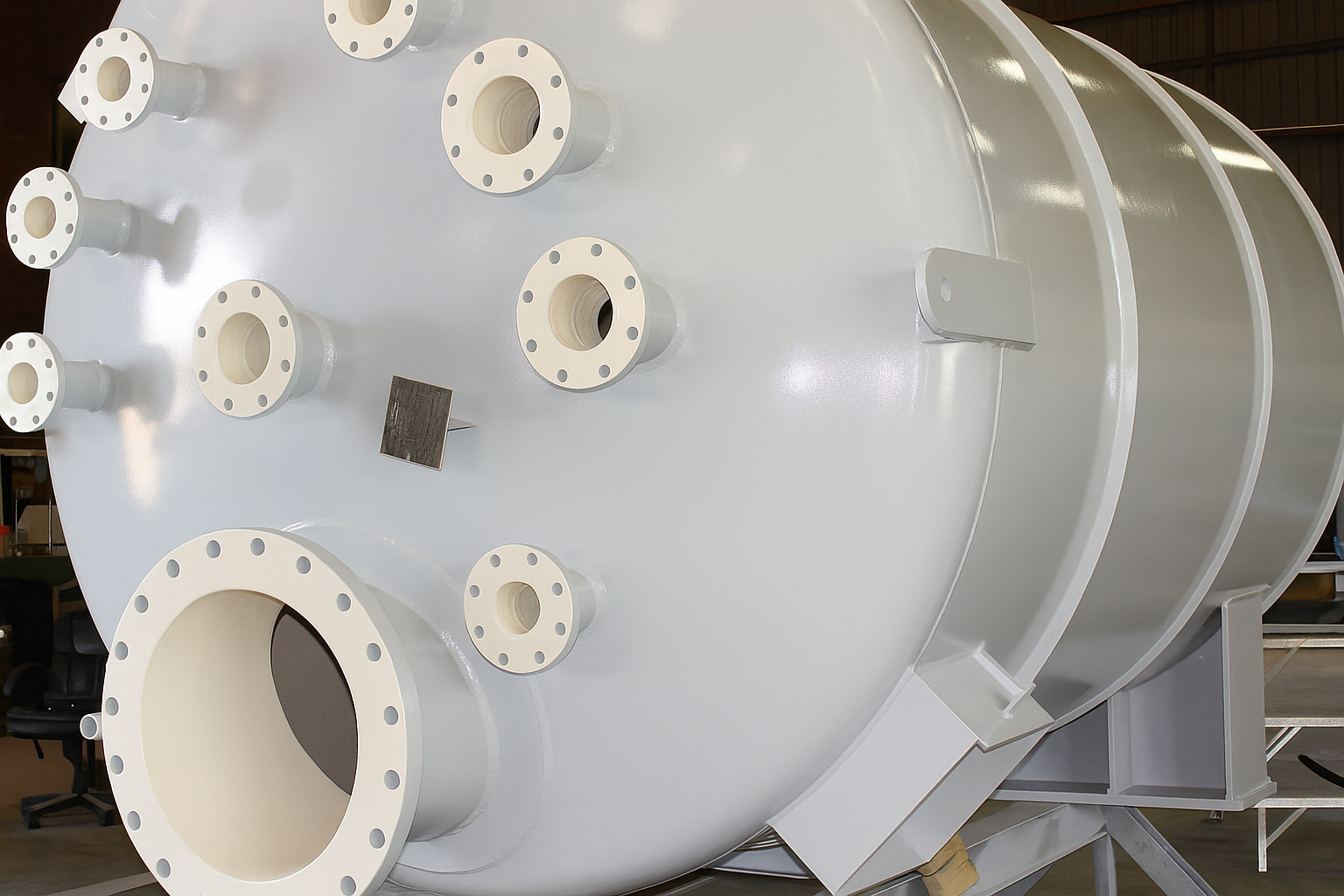

Curran International provides expert applications to pressure vessels, flanged pipe, and drums using a wide range of engineered protective coating.

We have application expertise using high functionality coatings:

Provides smooth, non-stick surface for improved flow and reduced buildup

Maintains integrity in extreme thermal conditions

PTFE, PFA, FEP and ETFE fluoropolymer resins are marginally differentiated in mechanical performance but offer immersion resistance up to 500F

Applied as a dry powder which melts and cures to a uniform coating thickness

Designed specifically to protect industrial components from corrosive environments

PFA has a slick, none stick surface that resist fouling, buildup, and conamination

Having wide chemical resistance for chemical storage and transport applications.

Used for ISO containers, chemical transport, pressure vessels, and heat exchangers

Fluoroelastomer Viton is an elastomeric two component coating suitable for a wide range of vessel substrates, offering exceptional protection in demanding environments.

Exceptional barrier properties

Maintains integrity under sun exposure

Withstands aggressive chemical environments

Thermal spray atomizes alloy wire which is sprayed onto a substrate, improving galvanic protection and inhibiting corrosion.

Gas acetylene and arc spray application methods are used to apply Nickel, Stainless, and surface hardening materials.

Thermal spray applications to pipe OD, and large diameter pipe ID, Curran has field application experience.

Please enter your name and email. We’ll be in touch soon.