Advanced thermal spray technology applies corrosion-resistant alloys directly to industrial equipment—even in-service assets. Curran International delivers field-ready solutions using gas acetylene and electric arc methods to protect critical infrastructure against aggressive environmental damage.

Often utilized to strengthen and build up existing substrate. Can be coupled with a Curran Coating to provide an even more robust system.

Protects production risers, flowlines, and wellhead systems from harsh marine environments with salt spray and constant moisture exposure.

Shields structural steel and piping from weather-related deterioration, extending asset life and reducing maintenance costs.

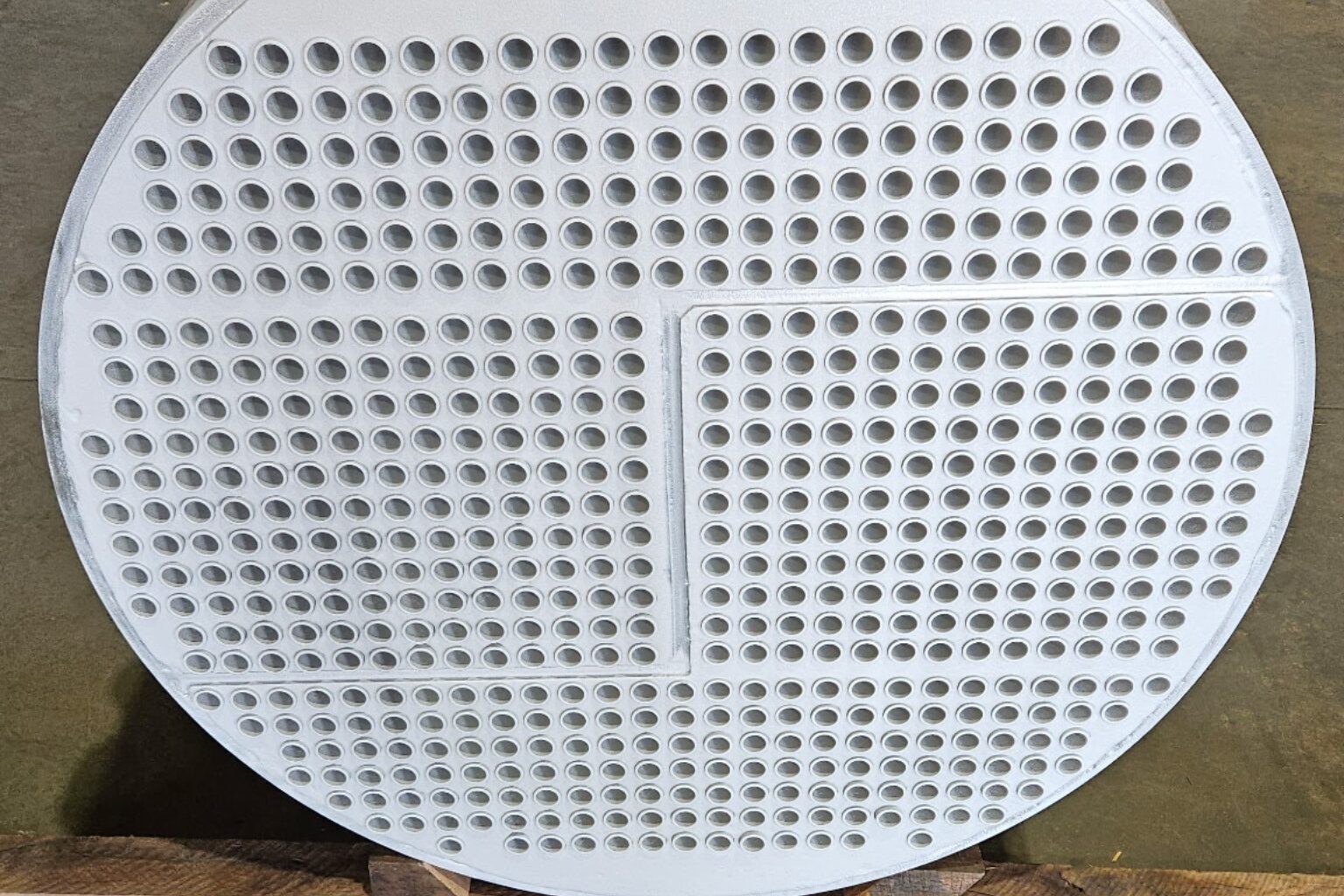

Provides protective lining for drums and vessels, preventing product contamination and extending equipment service life.

Superior for large-scale projects requiring maximum efficiency. The electric arc method delivers higher production rates and creates denser coating deposition for enhanced protection. Ideal for new construction and major refurbishment projects where equipment access is unrestricted.

Perfect for in-situ applications where accessibility is limited. The gas acetylene rig provides enhanced portability for field operations, making it ideal for touch-ups and maintenance of in-service equipment without extensive downtime.

Lightweight protection with excellent atmospheric corrosion resistance. Forms a passive oxide layer for long-term protection.

Superior resistance to oxidizing environments. Contains chromium for enhanced protection against aggressive chemicals.

Cost-effective galvanic protection. Sacrificial coating that prevents substrate corrosion even when coating is damaged.

Premium alloys for extreme environments. Withstands high temperatures and aggressive chemical exposure in industrial settings.

Please enter your name and email. We’ll be in touch soon.