Curran enhances distillation tower performance by applying REO Surface Treatment to internal packing and wash beds. This advanced, water-based treatment deposits rare-earth oxides such as yttria (Y₂O₃) onto alloy surfaces as a low-density, non-continuous layer. With no measurable thickness, REO Surface Treatment adds zero thermal resistance while delivering exceptional resistance to fouling, reduced coke buildup, and high-temperature oxidation protection. The result is cleaner surfaces, sustained process efficiency, and extended service life in demanding high-temperature environments.

Wash‑bed packing fouls rapidly due to low liquid rates & high vapor velocity.

Typical wash beds reach critical ΔP in 18–24 months.

Rare earth oxide technology prevents fouling formation while maintaining optimal heat transfer on internal packing.

Continuous runs with no ΔP increase

Push turnaround schedules by an extra 1–2 years.

Maintain column efficiency and throughput.

Fewer change‑outs and hydroblasts.

Minimized entrainment & coke generation preserves HVGO recovery.

Less confined‑space entry for packing replacement.

Higher uptime means fewer energy‑intensive shutdown/startups.

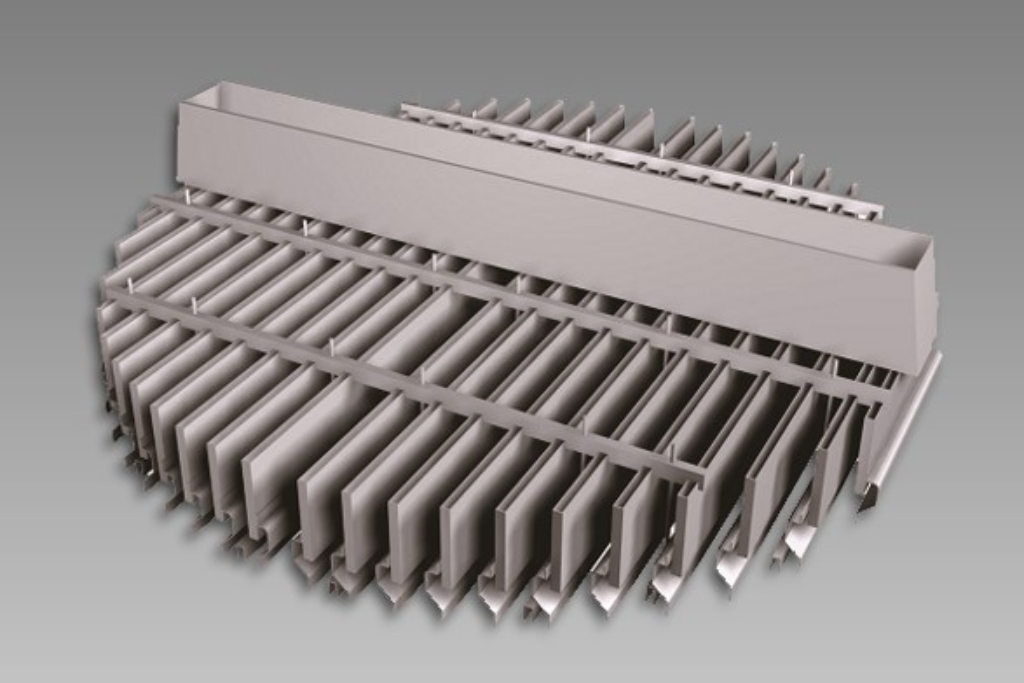

Grid Structured Packigng

Grid Structured Packing

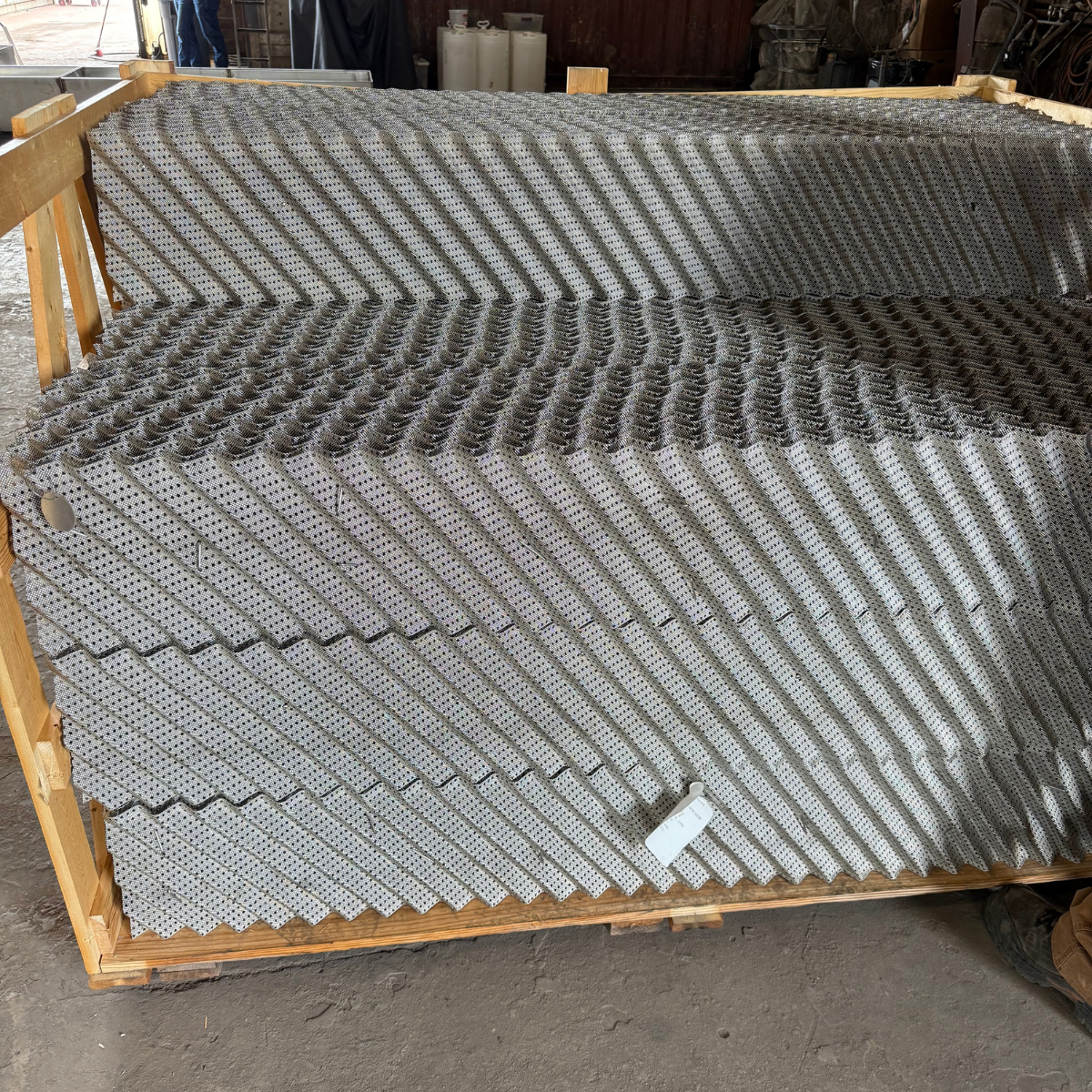

Corrugated-sheet Structured Packing

Corrugated-sheet Structured Packing

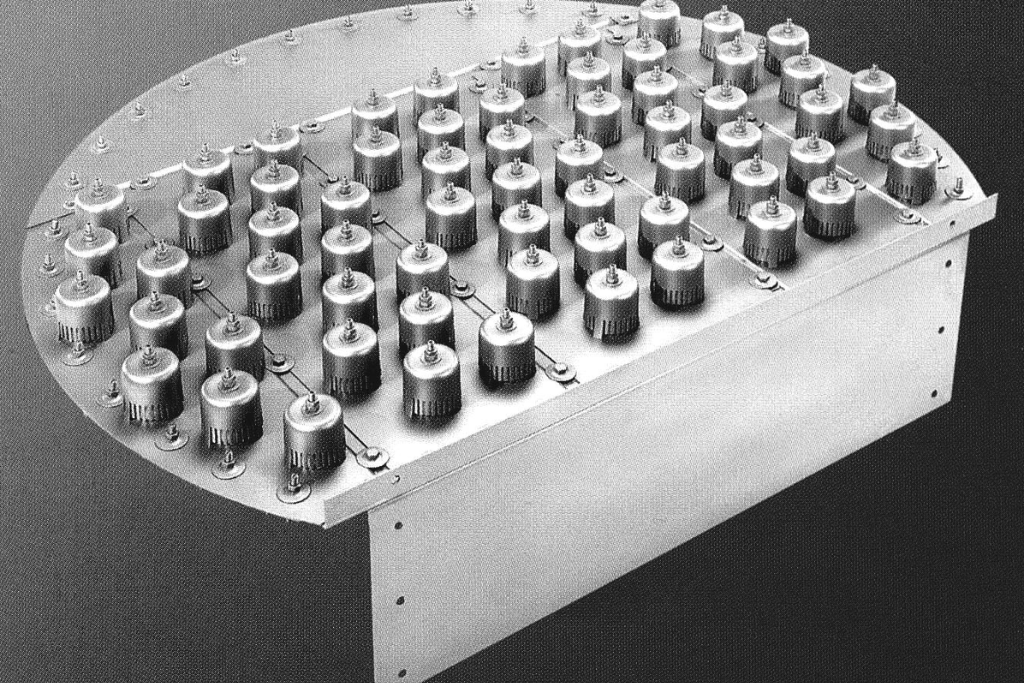

severe-service grid structured packing

severe-service grid structured packing

We begin with a thorough assessment of your heat transfer equipment challenges to get a clear understanding of your problem.

Our expert team analyzes your specific conditions to determine the most effective Curran solutions.

We develop a customized plan that may include our advanced coatings, tube liners, or grit blast cleaning services, designed to meet your unique equipment needs.

Our skilled technicians provide professional installation and application of our solutions, ensuring optimal performance and longevity for your heat transfer equipment.

01

Minimox is metallurgically bonded; longevity is limited only by base‑metal life. Field units exceed 4 years with no degradation.

02

No. The layer is sub‑micron and has no measurable thickness, so surface area and openness remain unchanged.

03

Yes—small areas can be spot‑treated and re‑cured with electric heaters.

04

Stainless Steels, 347H, 317L, Inconel, and other high‑alloy internals

05

Typical wash‑bed treatment fits into a 5‑to‑7‑day window, including cure.

Please enter your name and email. We’ll be in touch soon.