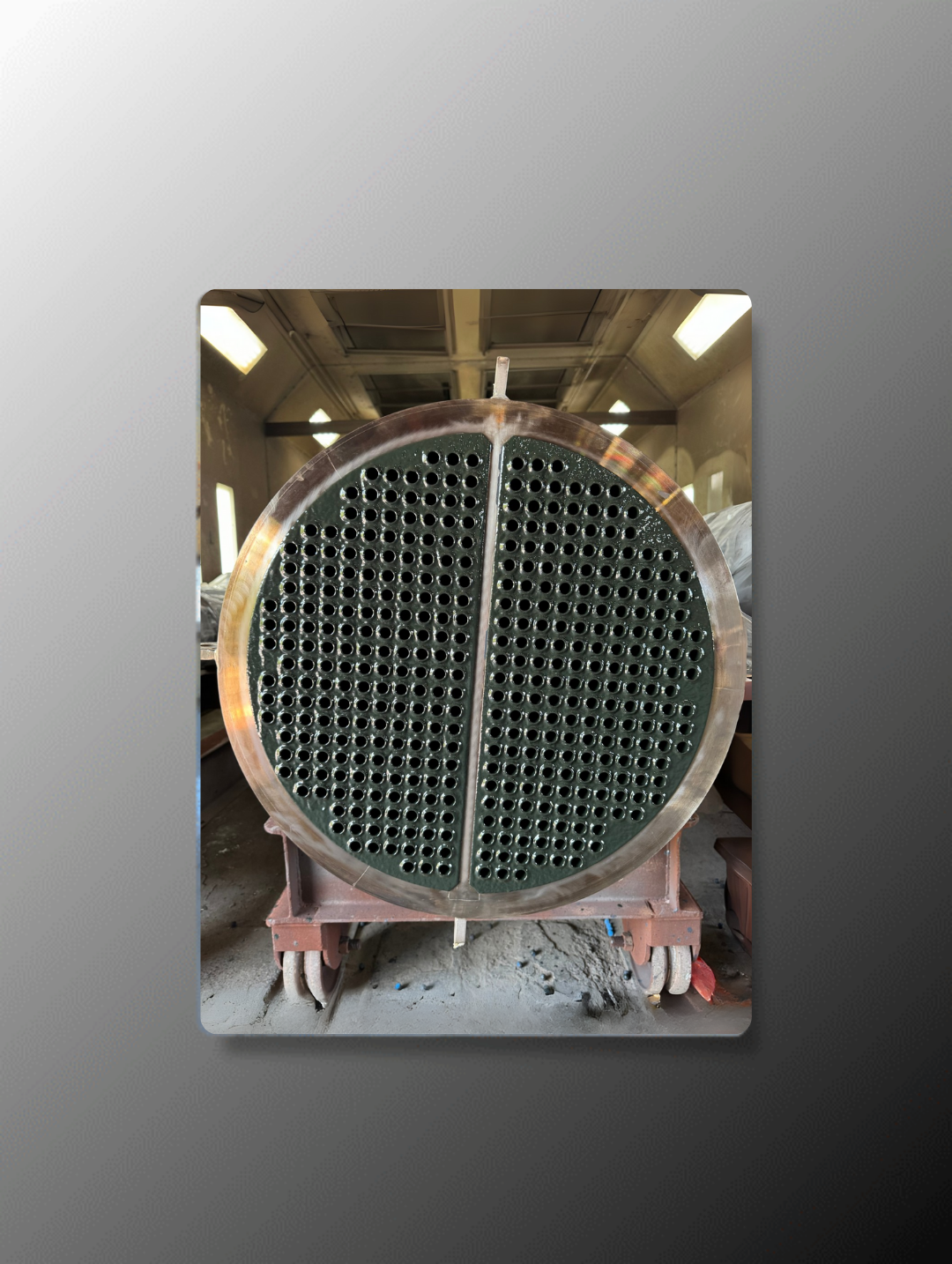

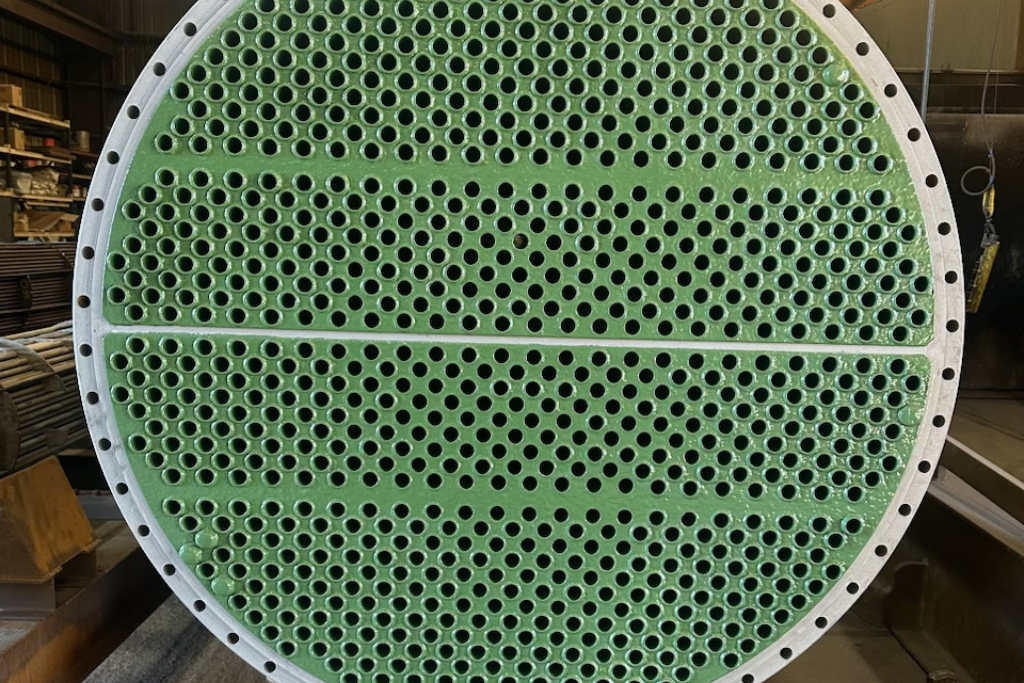

Curran 1000T is a revolutionary 2-part epoxy coating engineered specifically for cooling water exchangers in refineries and chemical plants.

Enhanced with graphene oxide technology, this field-proven coating creates an ultra-smooth barrier that prevents corrosion, eliminates fouling, and maintains heat transfer efficiency at temperatures up to 400°F.

With over 100,000 successful applications since the early 2000s, Curran 1000T has become the industry standard for protecting critical cooling water equipment.

Cooling water exchangers face relentless attack from corrosion and fouling, creating a costly cycle of failures and cleanings.

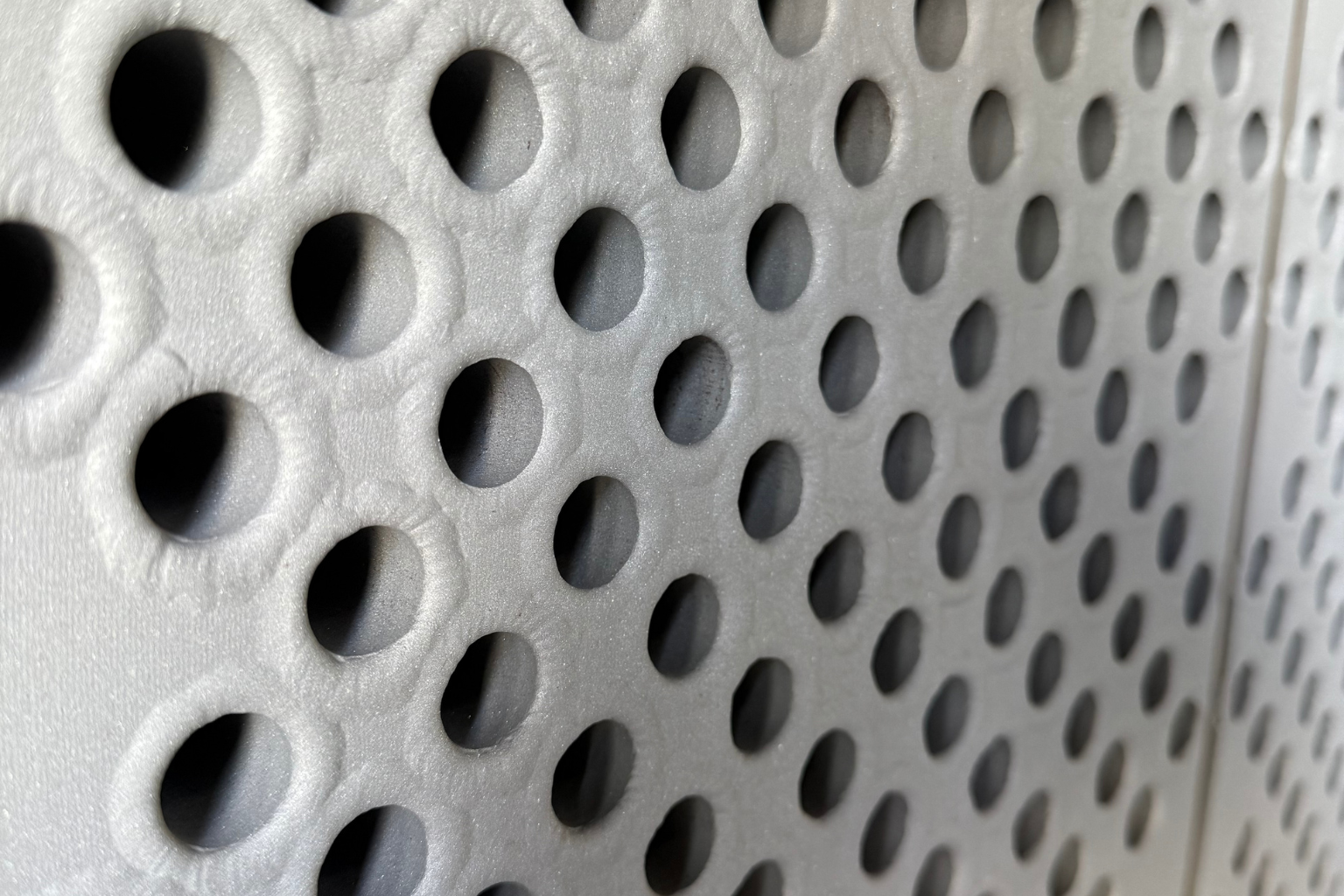

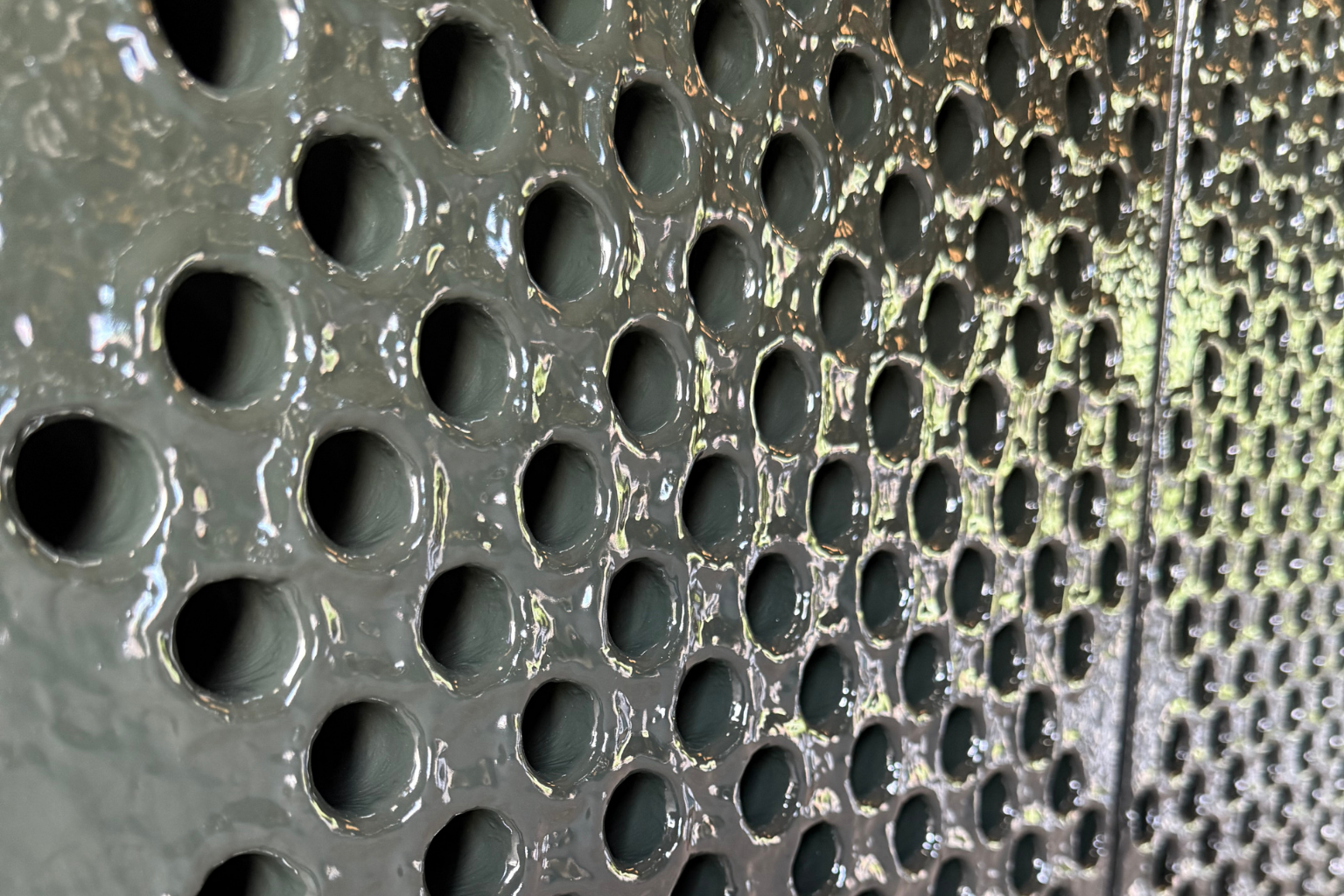

Severe fouling and corrosion plague unprotected carbon steel coolers, requiring frequent shutdowns

Average time between cleanings

Our graphene-enhanced coating transforms vulnerable equipment into long-lasting, high-performance assets.

Coated exchangers maintain like-new performance with minimal maintenance requirements

Proven service life with coating

Curran 1000T’s Graphene oxide technology creates a robust barrier protecting carbon steel and alloys from corrosion attacks

Ultra-smooth surface prevents biological growth and mineral deposits from adhering to tube surfaces

1.0 W/m·K thermal conductivity ensures optimal heat exchange while preventing efficiency losses from fouling

Documented case histories show service life extension from 2.5 years to 15+ years

Slippery surface allows easy removal of deposits during routine maintenance

Tolerates steam excursions up to 400°F without degradation or loss of adhesion

Up to 400°F (204°C) steam

250°F (121°C) continuous

Airless spray (60:1 pump)

Shop or field application

15+ years documented in cooling water

1.0 W/m·K conductivity

No efficiency loss

32-60 hours full cure

8 hours tack-free

Carbon steel, stainless

Copper alloys, titanium

Steam, hydrocarbons

Acids, caustics

8-14 mils (ferrous)

2-4 mils (non-ferrous)

Proven performance in cooling water services worldwide

| Equipment | 1000T Coated Carbon Steel Cooler |

| Challenge | High shell inlet temperature causing severe corrosion and fouling |

| Solution | Applied Curran 1000T at 8-14 mils to all tube surfaces |

| Results |

|

| Equipment | Atmos OVHD GAS OD Heat Exchanger |

| Challenge | Super Duplex tubes experiencing severe fouling issues |

| Solution | Curran 1000T siliconized epoxy applied at 3-5 mils |

| Results |

|

| Equipment | 6 FCC Unit Cooling Water Exchangers |

| Challenge | Corrosion and fouling limiting FCC unit efficiency |

| Solution | Coated main column and HP receiver condensers |

| Results |

|

| Equipment | Critical BLCOH Cooling Water Exchanger |

| Challenge | 6-month cleaning cycles causing $190M/year losses |

| Solution | New coated bundle installation at $25M cost |

| Results |

|

Proven performance in cooling water services worldwide

Active Super Major Refinery

• Lake Charles •

| Equipment | 1000T Coated Carbon Steel Cooler |

| Challenge | High temperature causing severe corrosion and fouling |

| Solution | Curran 1000T applied to all tube surfaces |

| Equipment | Atmos OVHD GAS OD Heat Exchanger |

| Challenge | Severe fouling issues in Super Duplex tubes |

| Solution | Applied Curran 1000T epoxy at 3-5 mils |

| Equipment | 6 FCC Unit Cooling Water Exchangers |

| Challenge | Corrosion and fouling limiting efficiency |

| Solution | Coated main column and HP receiver condensers |

| Equipment | Critical BLCOH Cooling Water Exchanger |

| Challenge | Long cleaning cycles causing $190M/Yr losses |

| Solution | New coated bundle installation |

Discuss your heat exchanger corrosion challenges and operating conditions with a Curran team member.

Curran 1000T is specified based on operating temperatures, substrate/metallurgy, service media, and equipment type.

Coordinate scheduling to ensure your unit is returned to site on time, whether it's shipping from your facility or directly from a fabricator.

Expert application with full QC documentation provided. Third-party inspection available upon request. Unit is returned to site ready for installation.

01

Curran 1000T is enhanced with graphene oxide technology and specifically formulated for high-temperature immersion service. Unlike standard epoxies, it maintains adhesion through multiple steam-out cycles up to 400°F and provides superior foul release properties.

02

Yes, Curran 1000T can be applied to both new and used equipment. Used equipment requires proper surface preparation including degreasing and grit blasting to SSPC-SP10/NACE 2.0 standards.

03

Field data shows Curran 1000T lasting 15+ years in cooling water service. We have documented cases of coated exchangers operating successfully for over 15 years with minimal maintenance.

04

Most facilities see payback within 6 months due to reduced cleaning frequency, extended run times, and eliminated emergency repairs.

05

Curran 1000T has a thermal conductivity of 1.0 W/m·K at typical thicknesses. By preventing foulant buildup, it improves overall heat transfer and avoids the performance cuts seen in uncoated exchangers over the course of the run.

Please enter your name and email.

We’ll email the data sheets shortly.