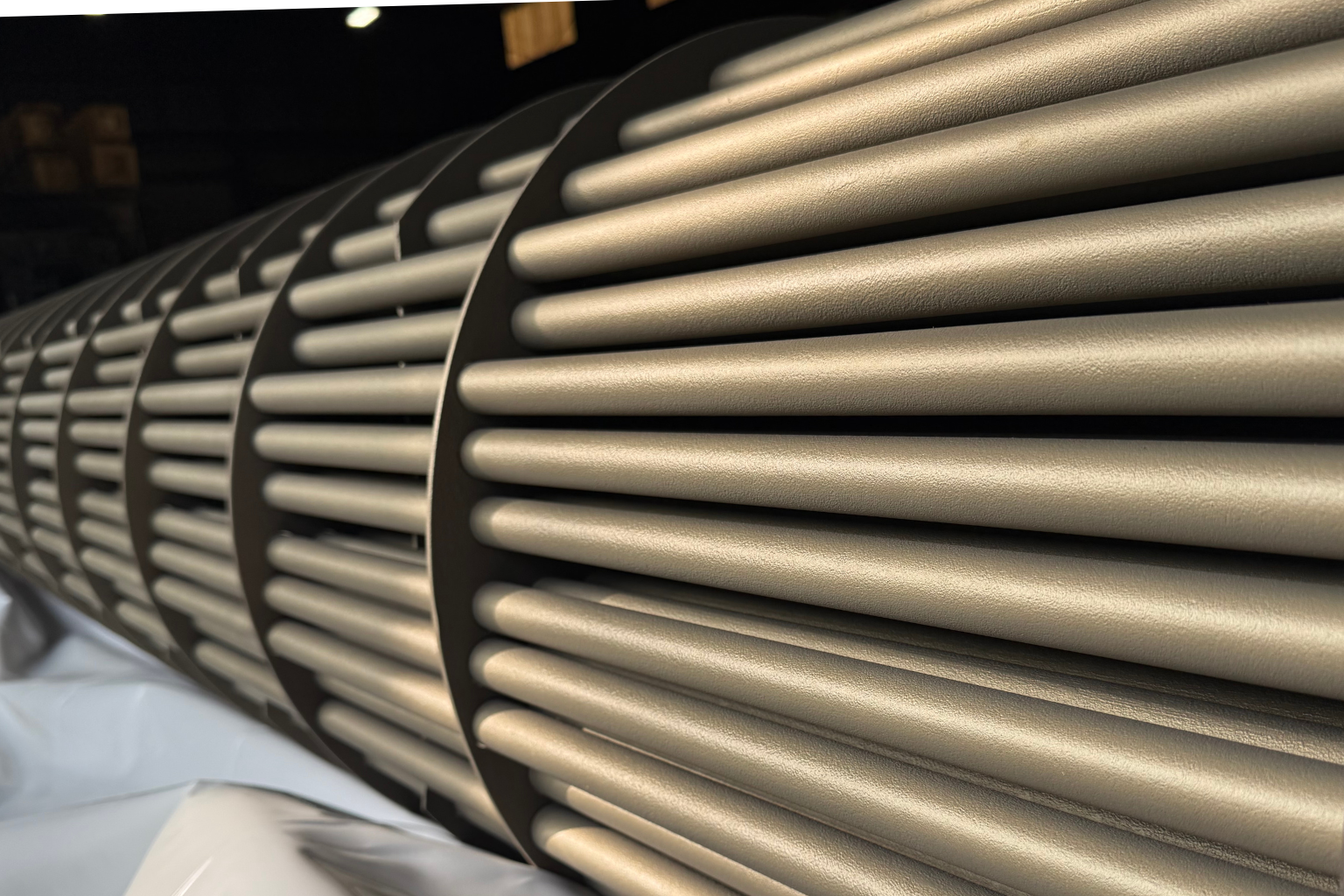

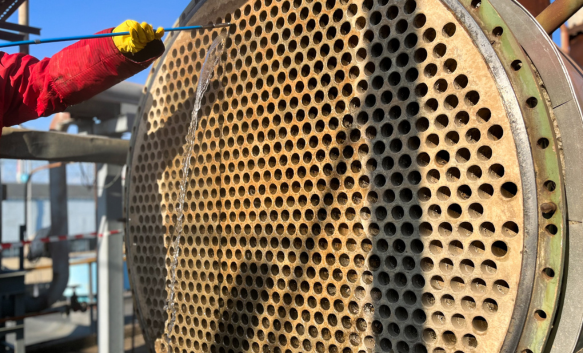

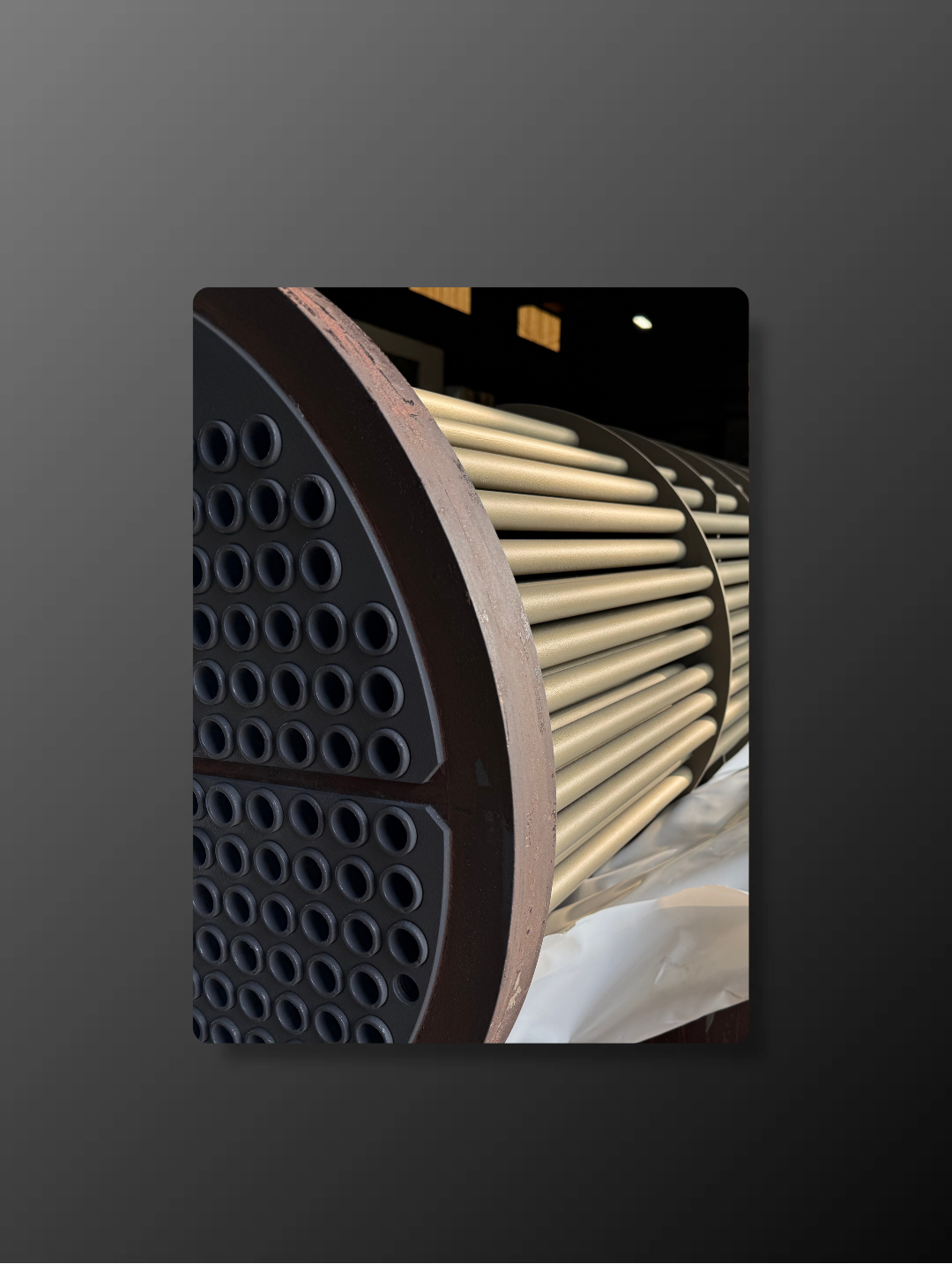

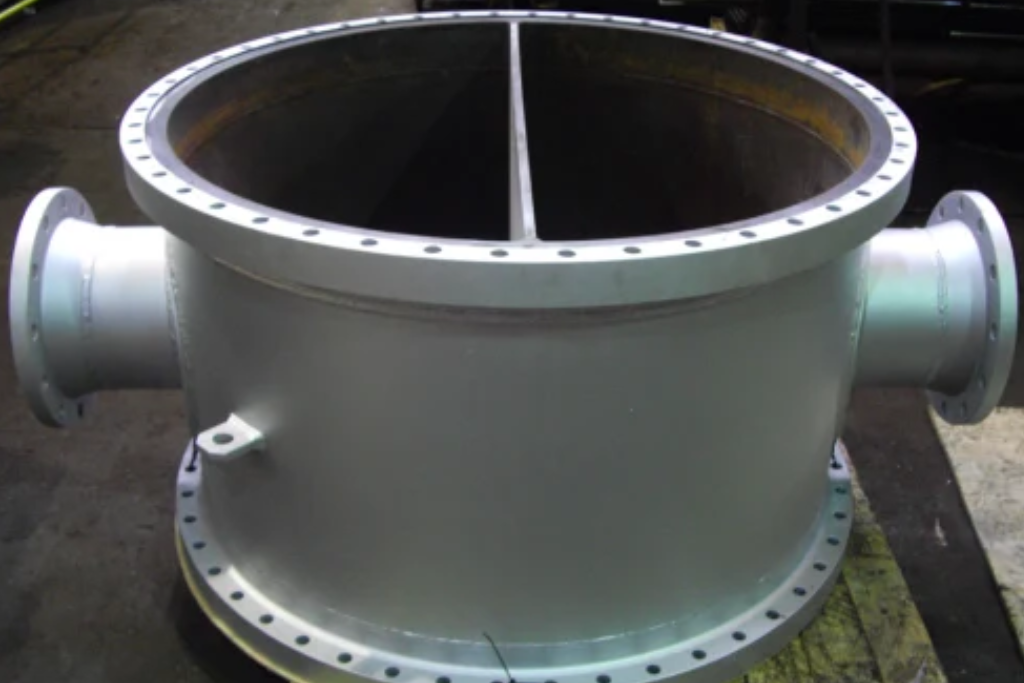

Curramix 2500 is an advanced single-part ambient-cure anti-coking ceramic coating engineered specifically for high-temperature metal substrates operating up to 2000°F (1093°C). A durable, thin-film coating engineered to protect critical exchanger surfaces in severe fouling environments. This state of the art coating technology delivers exponential improvements in thermal cycling and anti-coking properties for heat exchanger tubes (ID & OD), tube sheets, channels, and components.

Offshore platform condensate stabilizer without maintenance

Reduced from 3 annual cleanings to zero per year

Thermally cycled performance capability

Heat exchangers in FCC bottoms/slurry and crude heater service experience severe fouling, forcing annual cleaning cycles and reducing thermal efficiency by 45-75% within 6-18 months.

Typical performance loss within 200 days

Curramix 2500’s ceramic matrix provides exceptional foul-release properties and thermal shock resistance, maintaining heat transfer performance for 2+ years without cleaning interventions.

Efficiency maintained after extended operation

Proven 2+ year operation without maintenance in condensate stabilizer service at 350°F

93% performance retention vs. 75% degradation in uncoated exchangers after 20 days

2000°F thermally cycled capability for crude heaters and high-temperature process exchangers

Requires only low-pressure cleaning vs. high pressure hydro blasting and aggressive mechanical cleaning.

Click here for post cleaning guidelines

VOC exempt formulation meets environmental regulations without performance compromise

Up to 2000°F (1093°C) thermally cycled

Proprietary

5–7+ years

Excellent thermal shock resistance

Variable, ambient cure is acceptable as well as force curing options.

Heat exchanger tubes (ID & OD), tube sheets, channels, crude heaters

Resistant to hydrocarbons, designed for anti-coking service

0.25–2 mils DFT

(6.4–50.8 microns)

Curramix 2500 is ideal for high-temperature heat exchanger fouling mitigation in FCC bottoms/slurry,

condensate stabilizer, and crude heater service

| Equipment | U-tube bundle in NGL unit, coated tube OD, 350°F condensate stabilizer bottom service |

| Challenge | Uncoated exchangers required hydroblast cleaning every 3-4 months due to severe fouling |

| Solution | Curramix 2500 applied to tube OD for foul-release protection |

| Results |

|

| Equipment | SA-213-T5 tubes, tube ID & tubesheets coated, 600°F operating temperature |

| Challenge | Severe fouling reduced Us/Uc performance to 25-45% within 6-18 months in uncoated exchangers |

| Solution | Curramix 2500 applied to tube ID & tubesheets for anti-fouling protection |

| Results |

|

| Equipment | 198 SA-179 U-tubes (1″ OD, 17′ length), tube side crude oil 187-295°F, shell side HVGO 350-525°F |

| Challenge | Annual cleaning requirements disrupting operations and reducing efficiency |

| Solution | Curramix 3500 applied to tube ID, Curramix 2500 applied to tube OD for comparative analysis |

| Results |

|

Curramix 2500 is ideal for high-temperature heat exchanger fouling mitigation

Active – Gulf of Mexico – Offshore Platform

| Equipment | U-tube bundle in NGL unit, coated tube OD |

| Challenge | Severe fouling required constant cleaning |

| Solution | Curramix 2500 applied to tube OD for foul-release protection |

Active – Texas – Gulf Coast Refinery

| Equipment | SA-213-T5 tubes, tube ID & tubesheets coated |

| Challenge | Severe fouling reduced Us/Uc preformance |

| Solution | Curramix 2500 applied to tube ID & tubesheets for anti-fouling protection |

Active – Confidential – Super Major Refinery

| Equipment | 198 SA-179 U-tubes (1″ OD, 17′ length), tube side crude oil 187-295°F, shell side HVGO 350-525°F |

| Challenge | Annual cleaning requirements disrupting operations |

| Solution | Curramix 2500 applied to tube OD, Curramix 3500 to tube ID |

Curran International: 15+ year partnership with Chevron developing next-generation anti-fouling coatings with tens of thousands of successful applications worldwide

Discuss your heat exchanger fouling challenges and operating conditions with a Curran team member.

Curramix 2500 is specified based on operating temperatures, substrate/metallurgy, service media, and equipment type.

Coordinate scheduling to ensure your unit is returned to site on time, whether it's shipping from your facility or directly from a fabricator.

Expert application with full QC documentation provided. Third-party inspection available upon request. Unit is returned to site ready for installation.

01

Curramix 2500 is designed to withstand extreme temperatures up to 2000°F (1093°C) and has been thermally cycled at these conditions.

02

Yes, Curramix 2500 can be applied in-situ with proper surface preparation procedures, minimizing turnaround downtime.

03

Click here for post coating cleaning guidelines.

04

Target DFT of 0.25-2 mils (6.4-50.8 microns) for optimal anti-fouling performance while minimizing thermal impact.

Please enter your name and email.

We’ll email the data sheets shortly.