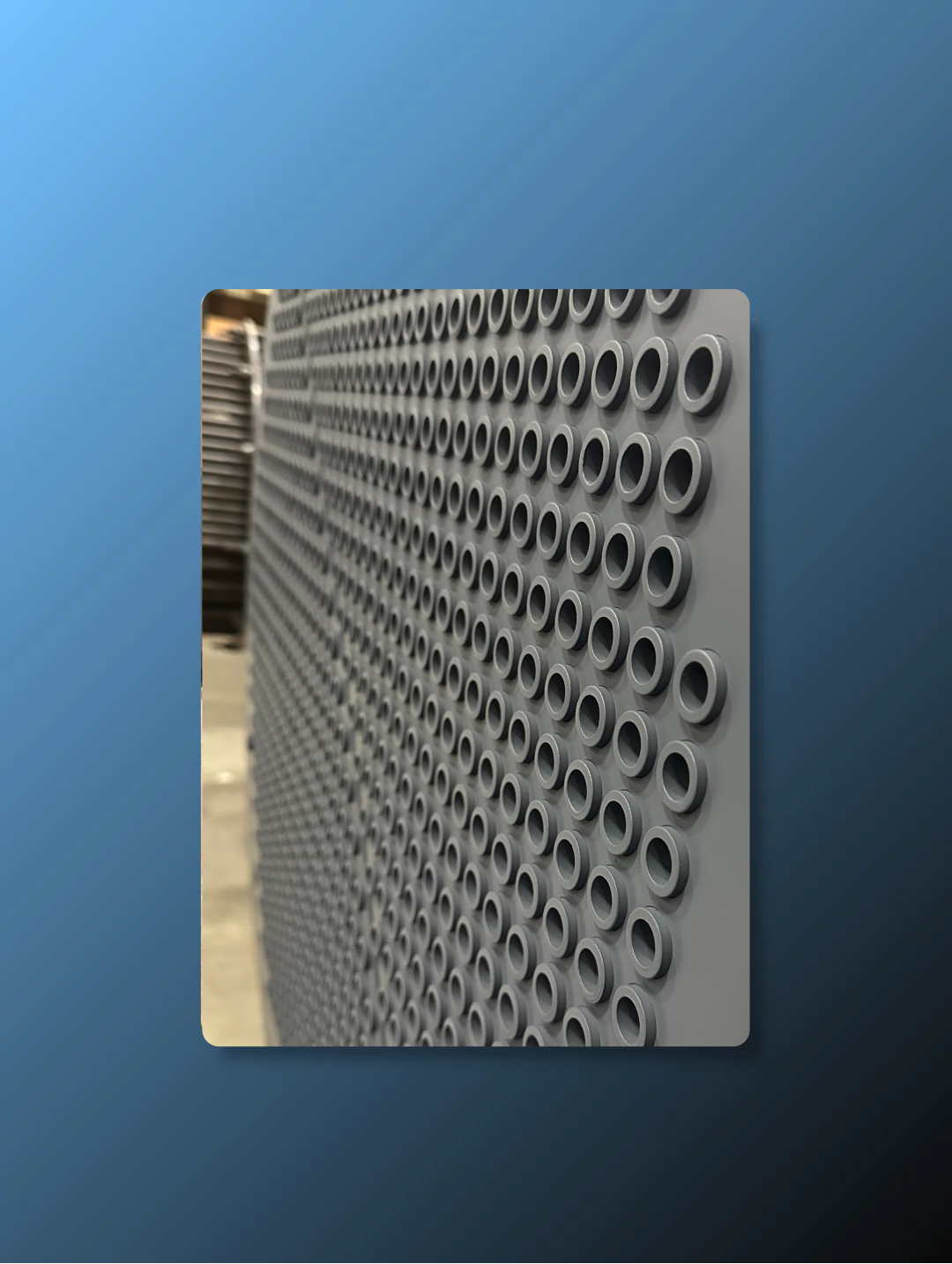

Curramix 3500 is an advanced multi-part ceramic coating system engineered specifically for high-temperature anti-fouling applications up to 750°F (400°C). This ultra-thin coating (1-2 mils DFT) reduces surface energy to <30 dynes/cm² while delivering exceptional foul release properties and thermal shock resistance.

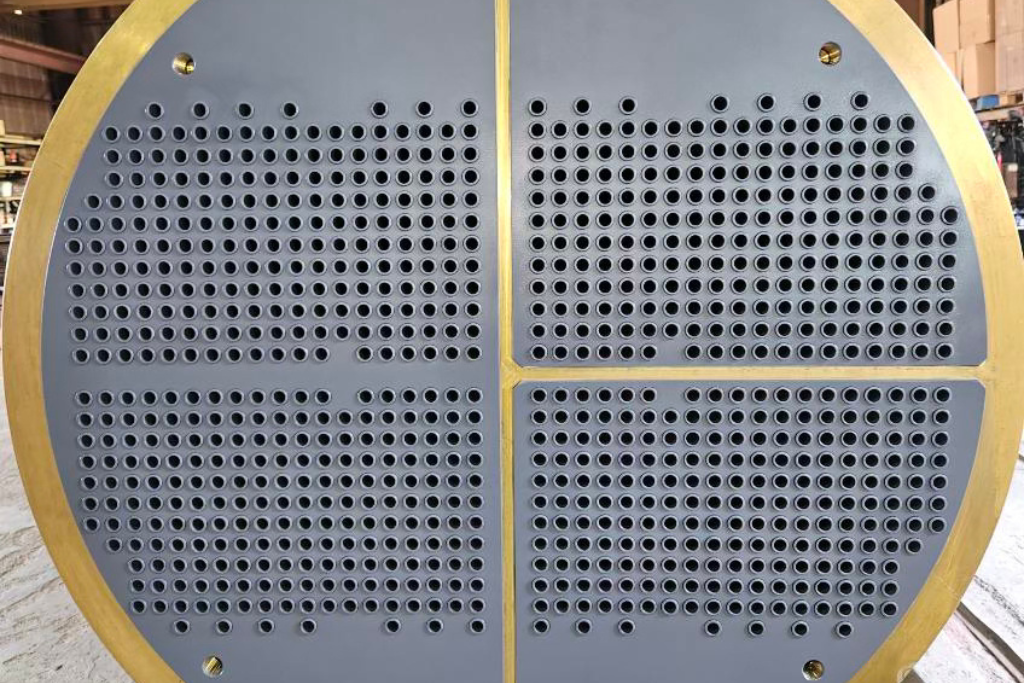

Designed for crude preheat exchangers, reactor feed effluent systems, and other critical heat transfer equipment, Curramix 3500 provides sustained fouling mitigation that extends run times up to 3x longer than uncoated equipment.

High-temperature crude processing creates severe fouling challenges that devastate heat exchanger performance.

Two-Year Impact per uncoated exchanger

Advanced ceramic technology that maintains clean surfaces at extreme temperatures. With the Surface Energy of:

4x better release performance vs. uncoated steel

Proven 3+ years operation without cleaning events in feed preheat service

Maintain design LMTD performance with sustained 20% improvement vs. fouled conditions

Field trials demonstrate 3x longer operation between maintenance shutdowns

Lower furnace firing requirements with improved heat recovery efficiency

Eliminate routine mechanical cleaning and associated labor/material expenses

Enhanced reactor performance through better feed preheating and reduced backpressure

750°F (400°C) continuous immersion service

Proprietary

5–7+ years proven field performance, designed for extreme thermal cycling

Minimal: 1–2 mils DFT maintains heat transfer coefficient

500°F

Carbon steel, stainless steel, alloy heat exchanger materials

Resistant to hydrocarbons, crude oil, H₂S, CO₂ - contact Curran for specific conditions

1–2 mils (6.4-50.8 microns) single coat system

Proven performance in the most demanding crude processing applications

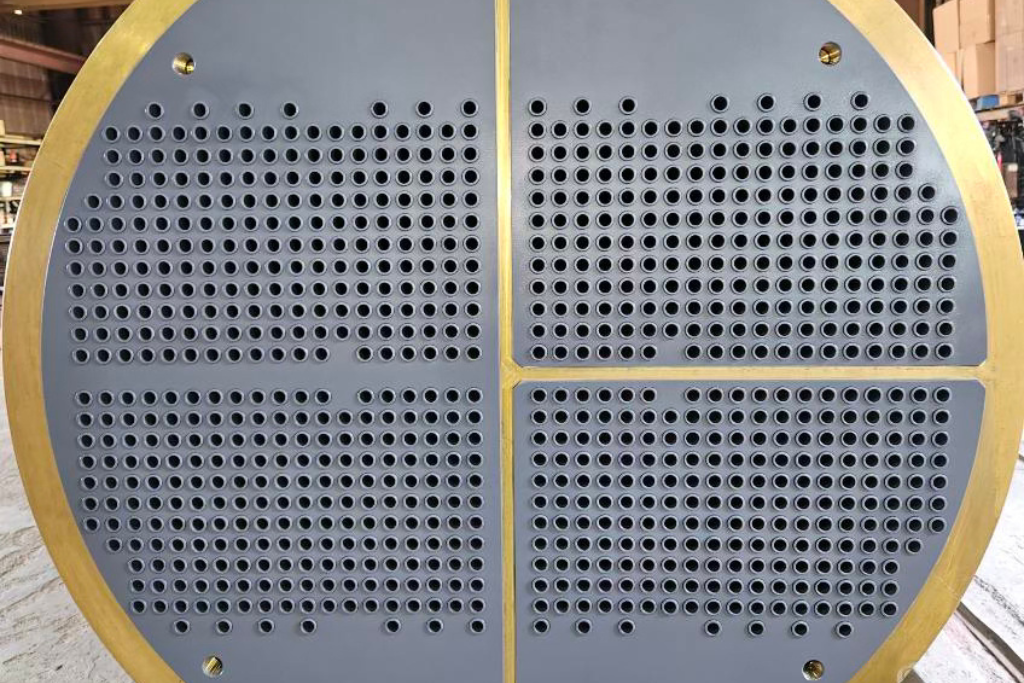

| Equipment | E-301/E-1365 Feed Preheat TRT3 – 345°F condensate service |

| Challenge | OD fouling with frequent maintenance cleaning cycles |

| Solution | Curramix 3500 applied to tube ODs at 0.4-1.7 mils thick |

| Results |

|

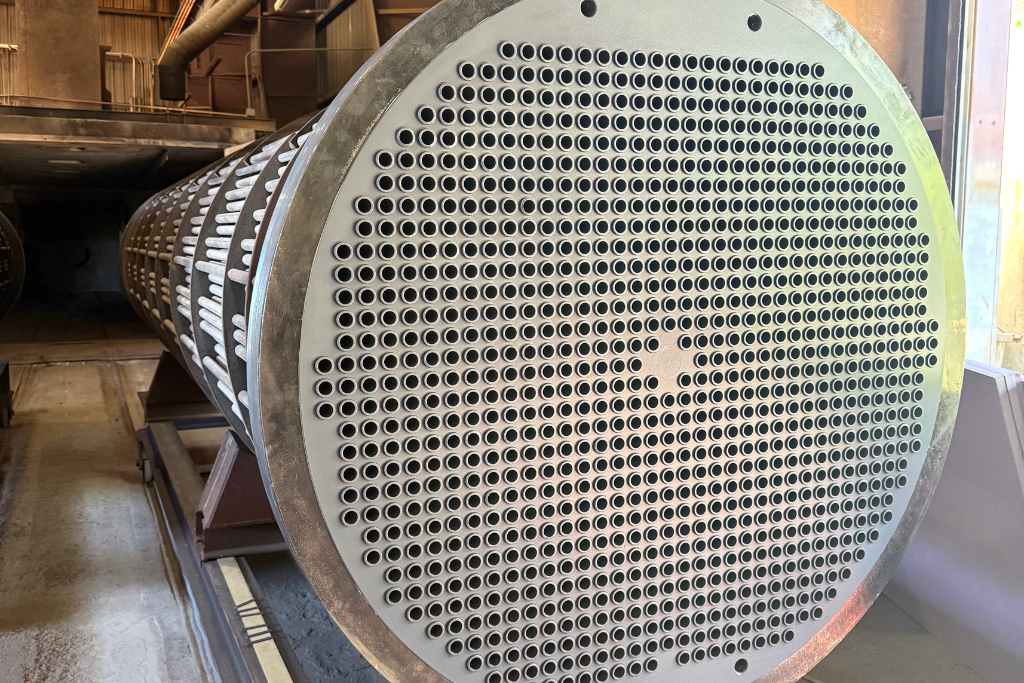

| Equipment | 600°F U-tube type, 3 exchangers, alloy tubes (321 SS, Cr-Mo) |

| Challenge | Severe tube-side fouling reducing heat transfer efficiency |

| Solution | Curramix 3500 applied to U-tube IDs |

| Results |

|

| Equipment | Stainless steel cooling water exchangers operated in parallel |

| Challenge | Fouling comparison between coated vs. uncoated performance |

| Solution | Curramix 3500 coating applied to parallel exchanger |

| Results |

|

| Equipment | FCC Bottoms/Feed Exchanger – tube IDs in slurry service |

| Challenge | Rapid fouling degrading heat transfer over 5-month operation |

| Solution | Thin film Curramix 3500 ID coating application |

| Results |

|

Proven performance in the most demanding crude processing applications

Active Installation – Texas Gulf Coast

| Equipment | E-301/E-1365 Feed Preheat TRT3 – 345°F condensate service |

| Challenge | OD fouling with frequent maintenance cleaning cycles |

| Solution | Curramix 3500 applied to tube ODs at 0.4-1.7 mils thick |

Active Installation – Gulf Coast

| Equipment | 600°F U-tube type, alloy tubes, three exchangers |

| Challenge | Severe fouling reducing heat transfer efficiency |

| Solution | Curramix 3500™ applied to U-tube IDs |

Active Installation – Texas Gulf Coast

| Equipment | Stainless steel cooling water exchangers |

| Challenge | Fouling: coated vs. uncoated performance |

| Solution | Curramix 3500™ coating applied to parallel exchanger |

Validated Performance – FCC Servic

| Equipment | FCC Bottoms/Feed Exchanger – tube IDs in slurry service |

| Challenge | Rapid fouling degrading heat transfer over 5-month operation |

| Solution | Curramix 3500™ ID coating application |

Curran International: 15+ year partnership with Chevron developing next-generation anti-fouling coatings with tens of thousands of successful applications worldwide

Discuss your heat exchanger fouling challenges and operating conditions with a Curran team member.

Curramix 3500 is specified based on operating temperatures, substrate/metallurgy, service media, and equipment type.

Coordinate scheduling to ensure your unit is returned to site on time, whether it's shipping from your facility or directly from a fabricator.

Expert application with full QC documentation provided. Third-party inspection available upon request. Unit is returned to site ready for installation.

01

Curramix 3500 is designed for continuous immersion service up to 750°F (400°C) with excellent thermal shock resistance for cycling applications.

02

The coating performs effectively at 0.25-2 mils DFT (6.4-50.8 microns), minimizing impact on heat transfer while providing superior foul release properties.

03

Minimum SSPC-SP 10/NACE 2.0 surface cleanliness with 5-micron profile using 100-120 mesh abrasive. Chlorides must be <10 ppm.

04

Yes, after proper cleaning and surface preparation. The coating can restore fouled equipment to like-new thermal performance.

Please enter your name and email.

We’ll email the data sheets shortly.