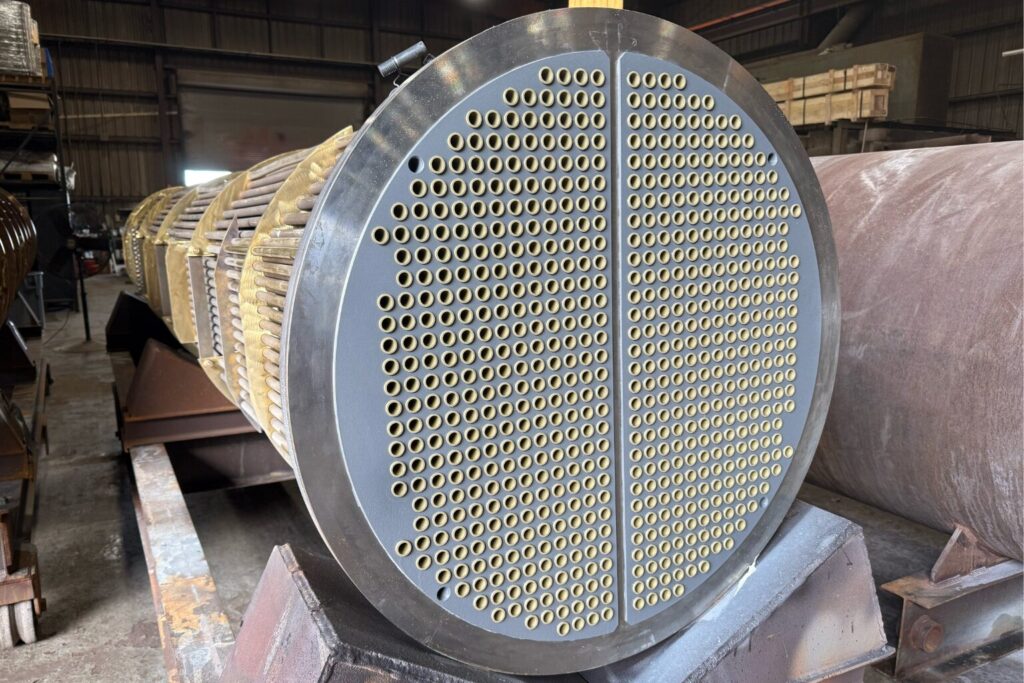

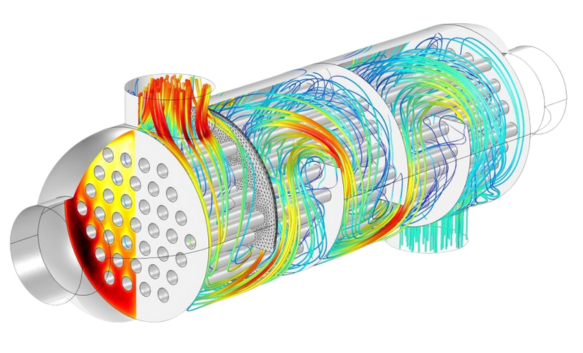

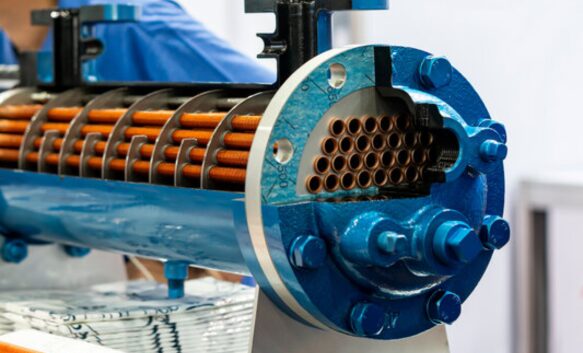

Curran International’s redesign and optimization services for exchangers was born out of a joint development agreement with a US oil and gas super major. We can transform your underperforming exchangers through our developed anti-fouling coating solutions, advance tube enhancements and metallurgy upgrades. We can provide you advanced thermal modeling and flow optimization forecasting. Our redesign & engineering solutions extend unit life, improve heat transfer efficiency, and reduce maintenance requirements. Most of our retrofit solutions are low cost and are deployed via replacing the tube bundles without any modifications to the existing shell and piping. This approach simplifies and shortens the turnaround activities.

1

Our Team has analyzed Over 15 crude preheat trains in refineries around the globe & we have retrofitted 50+ heat exchangers to improve preheat, desalting temperatures, and eliminate hydraulic constraints.

2

Designed a completely new preheat train for 50 K Bbl/day crude unit. The new design increased preheat by 100 ˚F and allowed for 10% higher feed rates.

3

Retrofitted feed-effluent exchangers for NHT with enhanced heat transfer surfaces. Impact: increase in production worth $1.1 MM/year, energy savings of $400K/year, reduction in GHG by 16 MT/day.

4

Our team redesigned 10 crude stabilizer reboilers with low density low fin tubes. the impact helped the site avoid a $10M+ capital project & $1.8 MM/year in maintenance savings.

5

Redesigned a regeneration gas (25% H2S) heater. Developed a unique pillow box design for CEU exchangers. Impact: new design eliminated LPO of $60MM experienced prior to the retrofit. The new pillow box design was shared with the industry due to safety implications.

6

Retrofitted horizontal thermosyphon reboiler in a chemical facility. Impact: dramatic reduction in fouling rates and avoidance of $ 5MM capital project to install bigger reboilers.

1

We deployed antifouling coatings and dual enhanced tubes for a condensate stabilizer on a production platform. Impact: reduction in fouling rates, increase in production rates, reduction in CO2 emissions. Total value creation of $20MM.

2

We have deployed antifouling coatings on over 200 exchangers in various services. Impact: reduction in fouling rates, increase in production rates, reduction in CO2 emissions. Total value creation of $35MM.

3

We deployed antifouling coatings to a single exchanger in clients crude pre heat train Flashed Crude vs Vacuum Resid exchanger just upstream of the atmospheric furnace. Impact: Fouling rates reduced by 50%, furnace inlet temperature increased by 1.5 ˚F that corresponds to reduction in the atmospheric furnace firing rates by 3.0 MMBTU/h.

4

Our team redesigned 10 crude stabilizer reboilers with low density low fin tubes. the impact helped the site avoid a $10M+ capital project & $1.8 MM/year in maintenance savings.

5

We deployed groovy fins for an air cooler as part of a modernization project. Impact: this retrofit allowed us to cancel a $2MM capital project to install a new bigger heat exchanger.

Standard redesigns often fail to address root causes of performance degradation, leading to recurring maintenance cycles and production losses averaging $50M annually across refineries.

of heat exchangers experience significant fouling within first year

Curran’s integrated approach combines proprietary anti-fouling technologies with enhanced tube geometries, extending run times from months to years while maintaining optimal heat transfer efficiency.

average ROI from tube enhancements coupled with anti-fouling coating applications

Transform underperforming units into reliable, efficient assets through proven engineering methodologies that optimize thermal performance while maintaining existing infrastructure investments.

Optimize heat transfer through advanced tube geometries and flow modeling

Lower furnace firing rates through improved preheat temperatures

Metallurgy upgrades mitigate corrosion and thermal stress failures

Eliminate hydraulic bottlenecks to achieve higher throughput rates

Tube bundle replacement approach minimizes shell modifications

Enhanced designs reduce fouling rates and maintenance frequency

Including: Process Flow Diagrams (PFDs), Piping and Instrumentation Diagrams (P&IDs), Process data sheets and drawings, Trend data, Discussion with client staff on priorities.

This Includes: Developing data sheets for the heat exchangers to be retrofitted, and developing purchase specifications for all exchangers to be retrofitted.

Curran can turnkey and work directly with the fabricators or allow the client to work with the fabricators. Then Review all bids and make recommendations.Next we work alongside your team review and approve all vendor documents (drawings, calculations, testing plans). Lastly we work with the 3rd party inspector to resolve any fabrication issues.

We deploy specialized coatings when advantageous to enhance performance and extend service life

Complete installation documentation and commissioning support for operational readiness

Curran supports calculation and verification of achieved performance improvements and economic benefits

Curran International delivers complete project execution from study phase through performance validation

Gather PFDs, P&IDs, process data sheets, and trend data for comprehensive analysis

Develop optimized heat exchanger designs with specifications and fabrication support

Provide vendor selection, document review, and quality assurance throughout manufacturing

Conduct post-installation analysis to verify achieved benefits and optimization

01

Our services cover crude preheat trains, reboilers, feed-effluent exchangers, air coolers, and specialized process applications across refineries and chemical facilities.

02

Our tube bundle replacement approach works within existing shells and piping, eliminating major modifications and reducing turnaround duration significantly.

03

Typical results include 10% capacity increases, 100°F temperature improvements, reduced fouling rates, and extended service life through optimized designs.

04

Yes, we offer complete project execution including vendor selection, fabrication oversight, quality assurance, and installation support throughout the project.

05

We conduct comprehensive post-installation analysis comparing actual performance to design predictions, providing documented evidence of achieved benefits.

Please enter your name and email. We’ll be in touch soon.