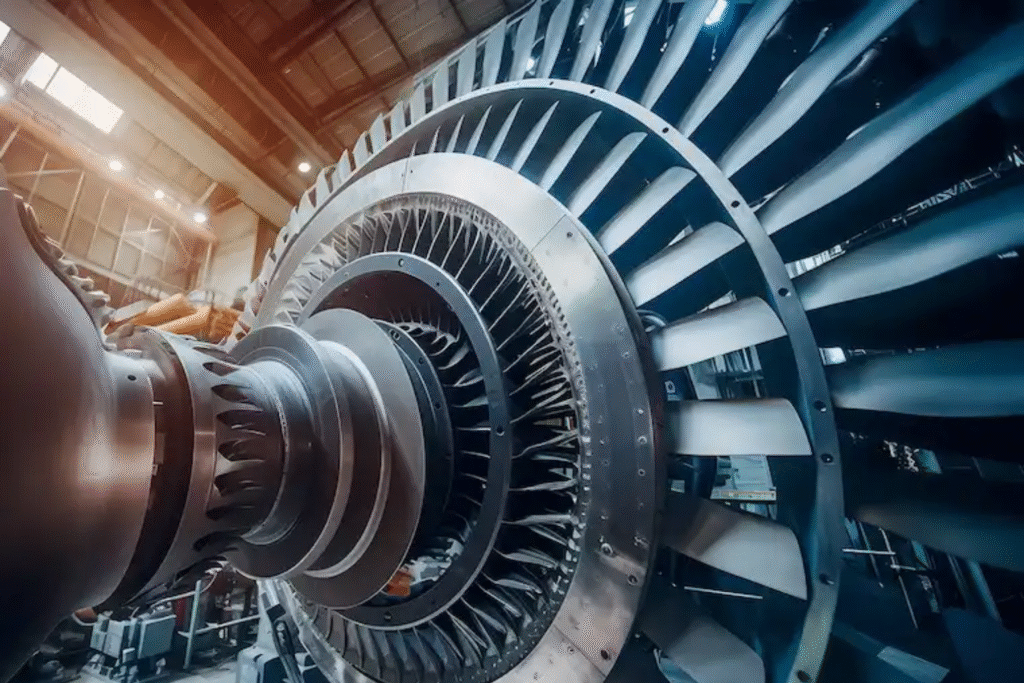

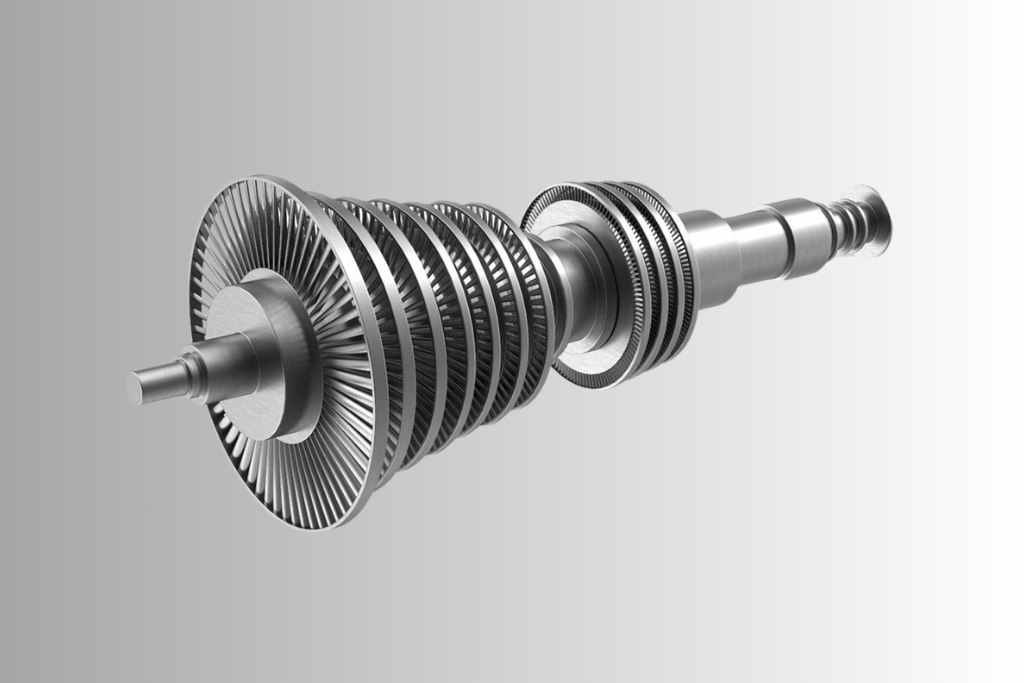

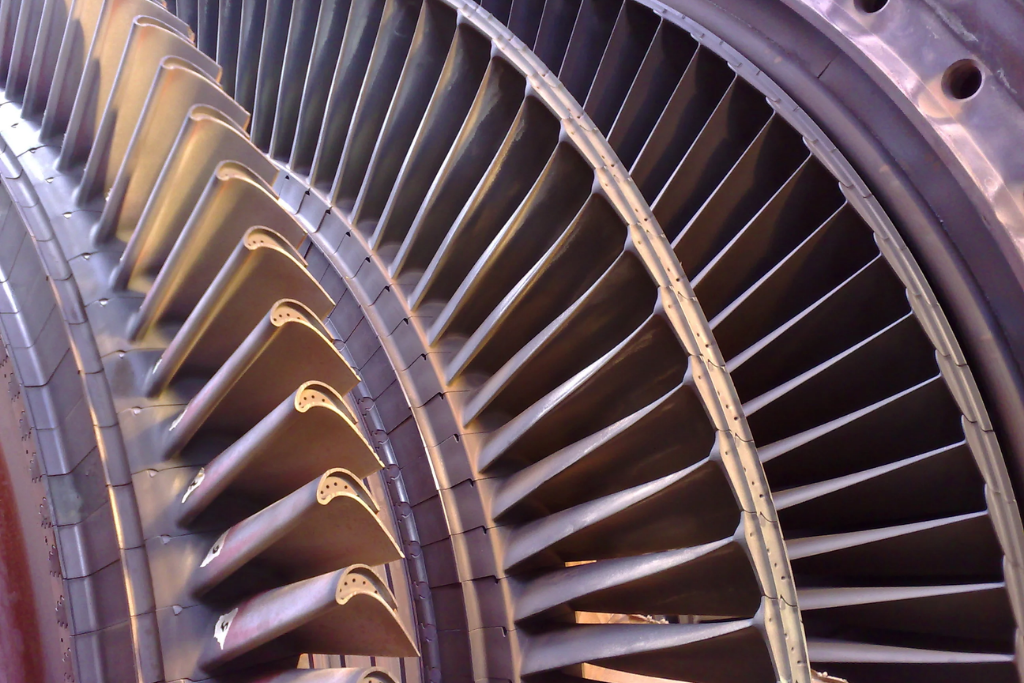

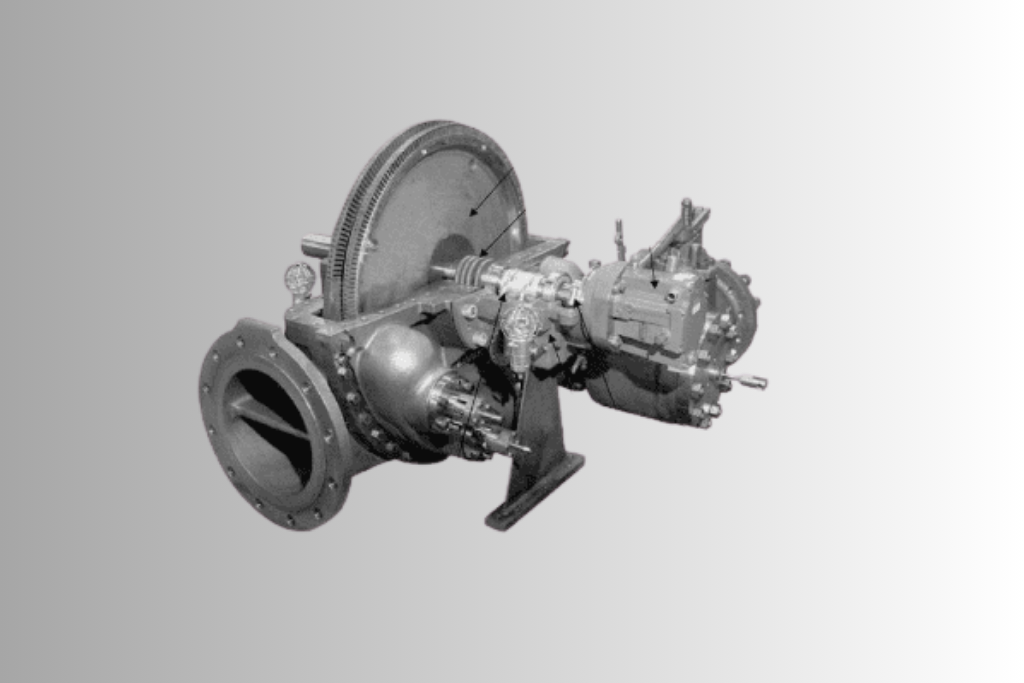

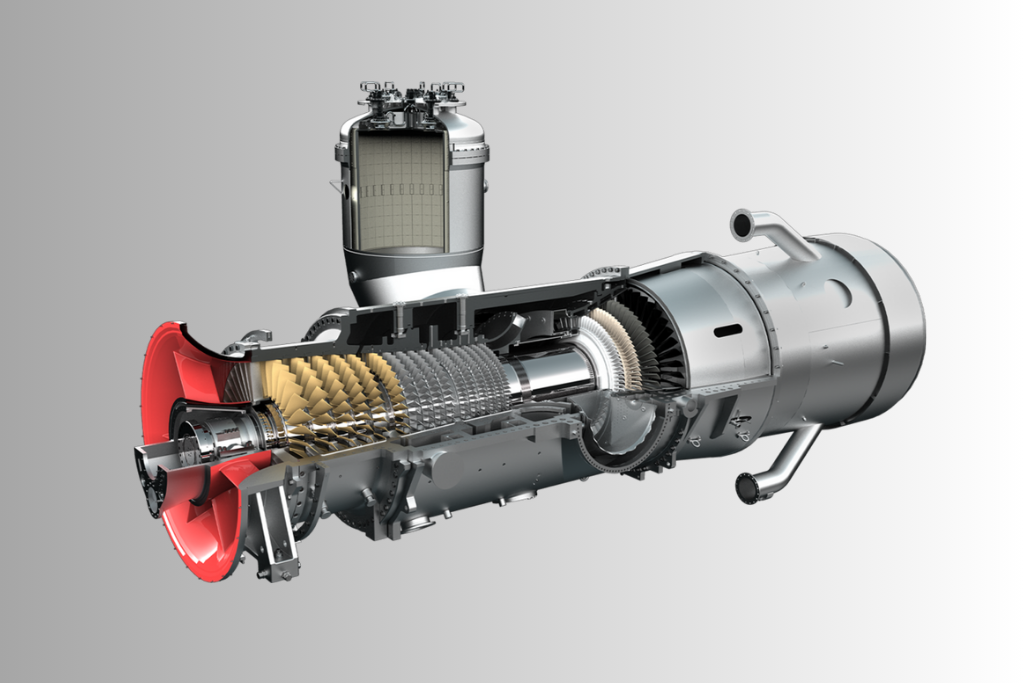

Curran’s Turbine Component Cleaning provides on-site grit blasting and glass bead dry abrasive blasting for steam and gas turbines. This specialized surface preparation service removes turbine scale while preserving blade trailing edges, yielding high-integrity NDE/NDT inspections for rotors, diaphragms, valve components, and shells

to meet all OEM specifications.

Multiple cleaning attempts often fail to achieve inspection-ready surfaces. Water-based methods risk equipment damage and require extended drying times.

Typical First-Pass Failure Rate

Predictable turbine inspection results the first time with complete containment and no fugitive dust escape.

First-Time Success Rate

Curran’s turbine cleaning method provides predictable inspection results while protecting critical components.

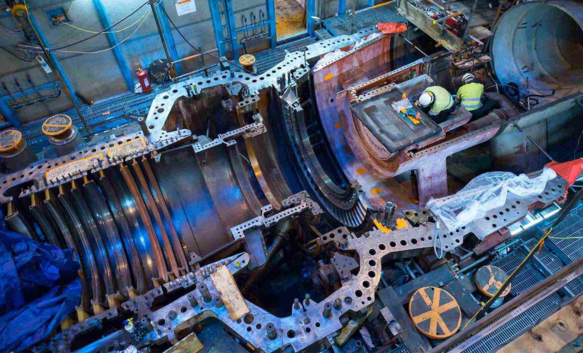

Our containment systems allow other crafts to work within close proximity, reducing overall outage duration and costs.

High-integrity surface preparation for accurate crack detection

Scale removal without metal loss on blade trailing edges

Predictable cleaning times enable better schedule coordination

Dust collection prevents damage to surrounding equipment

Meet specifications for GE, Siemens/Westinghouse, and Toshiba

All equipment and qualified crews provided

Partner with the turbine cleaning experts who have supported power generation maintenance for over 40 years

Discuss your turbine type and outage window

Get detailed scope and timeline

Curran provides all equipment and crews

Achieve inspection-ready components on schedule

01

Smaller turbine jobs complete in 3 shifts, while larger outages require up to 10 days. For example: 6 FD and ID fan rotating elements complete in 6 shifts; GE Medium Steam Turbine (14-stage rotor, 13-stage diaphragms) complete in 3 days.

02

Yes, our turbine tents completely cover components with tied-in electric dust collectors capturing all dust. Your area will be as clean or cleaner than before we arrive.

03

We maintain a national supplier network meeting OEM requirements. Common media includes virgin Aluminum Oxide (220 or 180 sieve), with recycled oxide available per client specifications.

04

Clients typically provide electrical tie-ins for dust collection, waste containers, scaffolding as needed, forklift support, service water and air. Curran provides all blast equipment, grit, containment, and diesel.

05

We have experience on GE, Siemens/Westinghouse, and Toshiba turbines, performing work to meet all manufacturer specifications.

Please enter your name and email. We’ll be in touch soon.