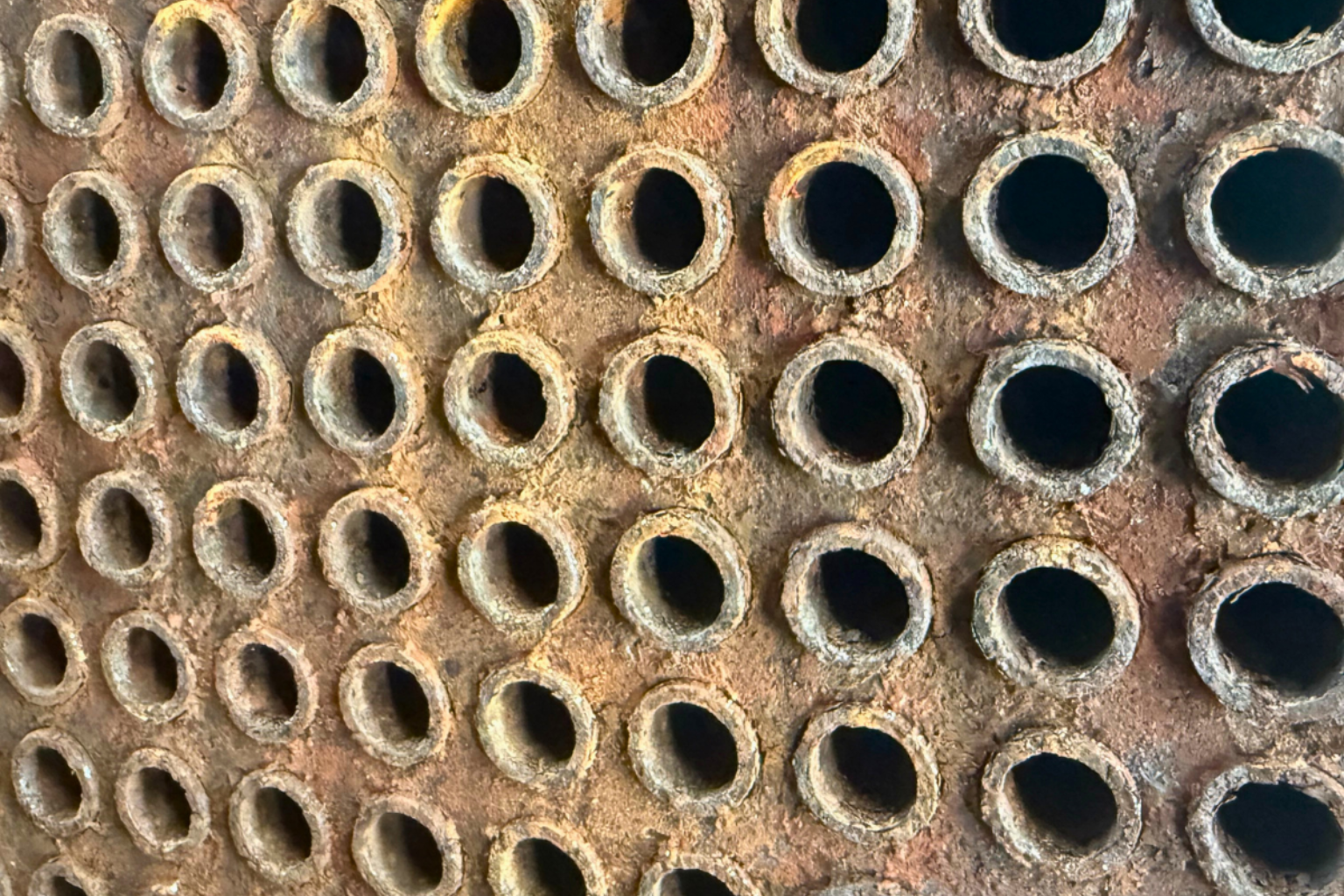

Shell and Tube Heat Exchanger Tube Repairs utilize hydraulically expanded tube liners and inserts to restore corroded, eroded, or thinning tubes to service. Our full-length tube liners provide a corrosion-resistant barrier inside parent tubes, while tube inserts (ferrules) protect localized wear areas.

Available in stainless steel, duplex, Inconel, CuNi, C276, and other specialized alloys, these solutions extend exchanger service life and mitigate the need for tube plugging or unit replacement.

Corrosion and erosion force frequent plugging or early replacement, reducing efficiency and increasing downtime.

Heat transfer loss from plugged tubes

Hydraulically expanded alloy liners restore performance and extend tube life without full re-tubing.

Cost Savings vs. Full Unit Replacement

Tube repair solutions restore damaged exchanger tubes with corrosion-resistant liners or inserts, extending service life and avoiding the need for plugging. The process maintains full heat transfer performance, allows targeted metallurgy upgrades, and minimizes downtime through efficient onsite installation. This cost-effective approach delivers major savings, often exceeding $500,000, while improving long-term reliability and operational efficiency.

Full-length tube liners and localized inserts restore corroded or eroded tubes to service, providing a corrosion-resistant barrier that extends operational life.

Alternative to tube plugging that maintains heat transfer capacity and prevents accelerated degradation in remaining tubes.

Opportunity to upgrade from carbon steel to higher-grade alloys including 304/316 SS, 825, C276, and other specialized materials.

Efficient onsite installation process with small crew footprint enables work on isolated units without complete operation shutdown.

Substantial cost savings compared to re-tubing or unit replacement, with most clients seeing savings north of $500,000.

Hydraulic expansion ensures metal-to-metal contact, preventing air gaps and maintaining efficient heat transfer.

Proven tube repair solutions with expert onsite installation and metallurgy upgrades

Reach out to discuss your tube repair requirements and schedule site assessment

Our team evaluates tube condition and determines optimal liner specifications and installation approach

Material selection, sizing, and installation timeline coordination with your turnaround schedule

Expert onsite installation with complete QC documentation and post-installation verification

01

Shell and tube heat exchangers, condensers, reboilers, coolers, heaters, and evaporators experiencing tube-side corrosion, erosion, or localized wear can benefit from our tube liner and insert solutions.

02

Installation time depends on the number of tubes and exchanger configuration. Our efficient onsite process with a small crew footprint minimizes downtime impact during turnarounds.

03

Most clients see cost savings north of $500,000 compared to re-tubing or unit replacement, while maintaining full heat transfer capacity and extending equipment service life.

04

We offer various alloys including stainless steel, duplex, Inconel, CuNi, C276, and other specialized materials selected based on your specific service requirements and corrosion resistance needs.

05

Our hydraulic expansion process ensures metal-to-metal contact between liner and parent tube, preventing air gaps and maintaining efficient heat transfer while providing corrosion protection.

Please enter your name and email. We’ll be in touch soon.