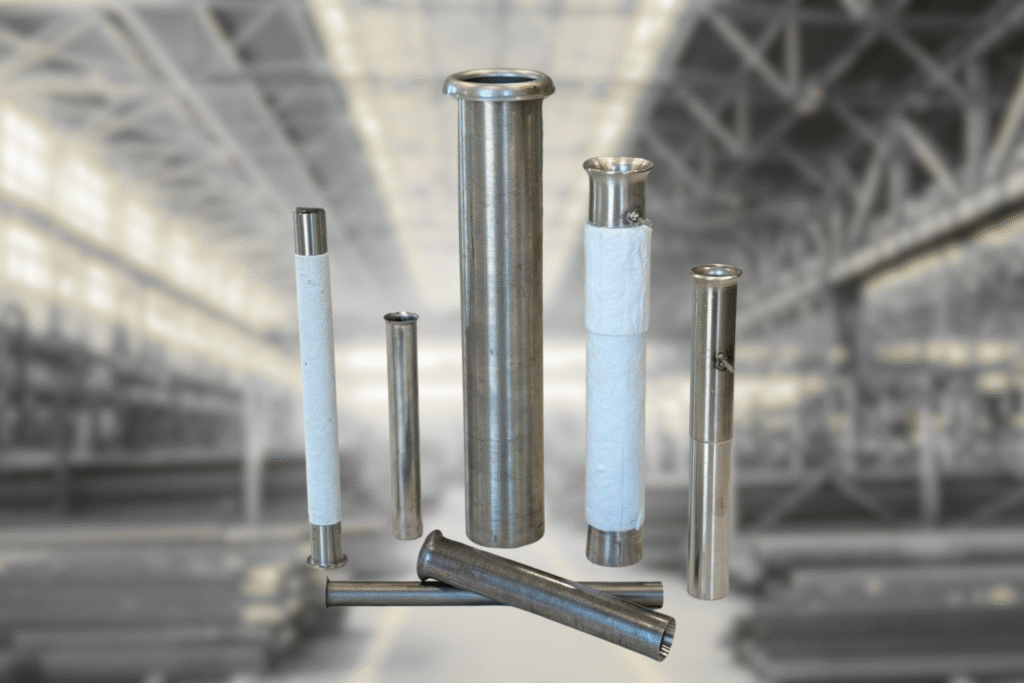

Alloy Tube Ferrules are short tubes or sleeves hydraulically expanded into parent tubes to act as a wear mechanism against erosion in areas experiencing severe wear and corrosion. These custom-manufactured inserts are available in various alloys including stainless steel, duplex, Inconel, CuNi, and C276, designed to upgrade metallurgy at critical wear points and extend equipment service life.

Curran International is a trusted supplier of tube ferrules, delivering precision-engineered solutions for refinery, petrochemical, and power generation facilities. With decades of field experience, Curran provides reliable installations that improve reliability, reduce maintenance, and maximize exchanger life.

Tube-End Erosion and Corrosion

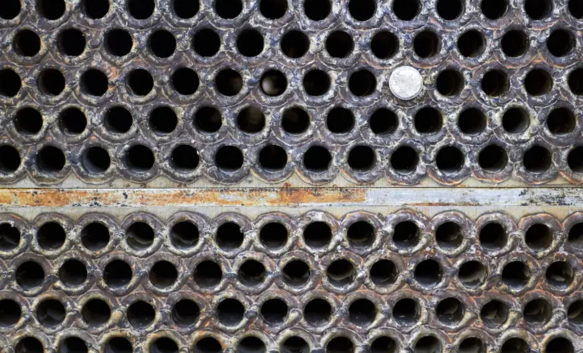

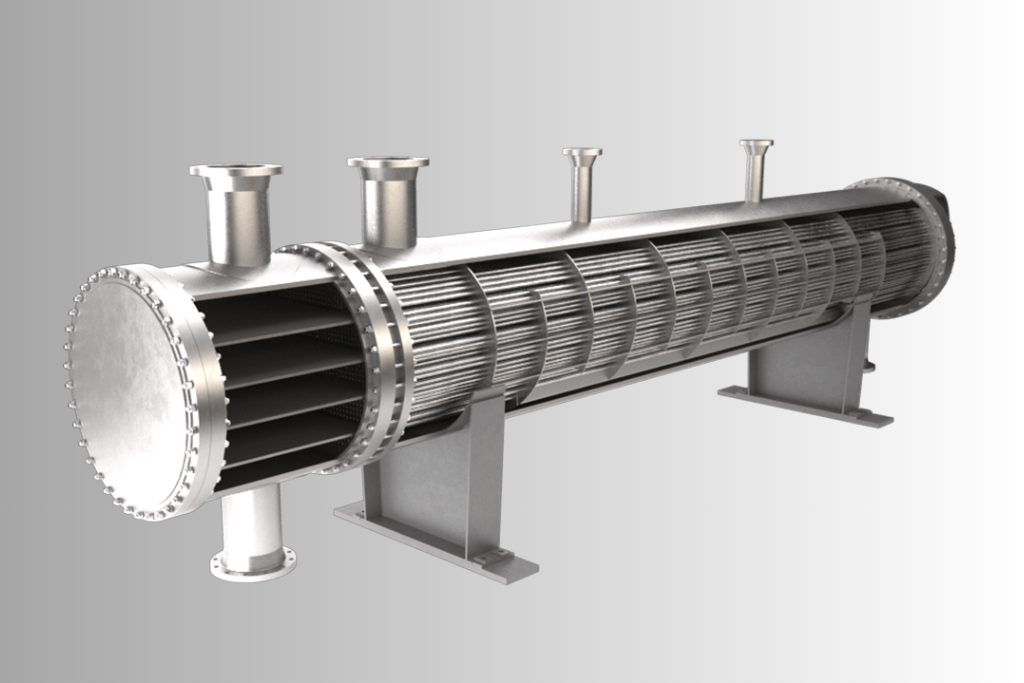

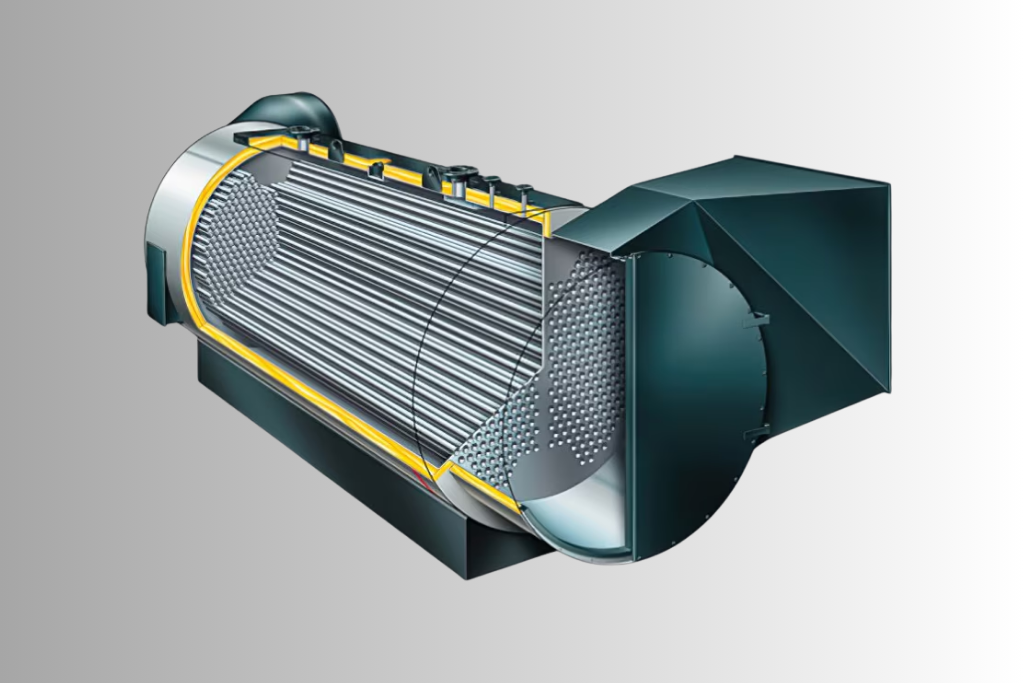

Heat exchanger tubes experience severe wear and corrosion at critical zones, particularly at tube ends and areas with high velocity flow.

Traditional carbon steel tubing cannot withstand aggressive process conditions, leading to premature failures and forced tube plugging.

Capacity Loss

Targeted Metallurgy Upgrade

Alloy Tube Ferrules provide corrosion-resistant barriers at critical wear points, allowing facilities to upgrade metallurgy without full re-tubing.

Custom alloy selection addresses specific process conditions while maintaining efficient heat transfer.

Heat Transfer Retention

Alloy Tube Ferrules protect high-wear tube-end zones from erosion and corrosion, helping maintain heat transfer efficiency and avoid premature plugging.

They offer a cost-effective way to upgrade metallurgy without full re-tubing, extending exchanger life and reducing long-term maintenance costs.

Tube Ferrules provide an alternative to plugging by protecting critical wear zones, allowing tubes to remain in service and maintaining heat transfer capacity

Target specific wear zones with upgraded alloys without the expense of complete re-tubing, providing corrosion resistance where needed most.

Efficient onsite installation with a small crew footprint allows for isolated unit work, reducing the need for complete operation shutdown.

Hydraulic expansion ensures metal-to-metal contact, preventing air gaps and maintaining optimal heat transfer performance.

Avoid premature equipment replacement by addressing localized wear issues with targeted alloy protection.

Select appropriate alloy based on process conditions and order properly sized annealed liners

Clean tube ID through grit blasting and measure parent tube dimensions for calibration

Install full-length liners into parent tubes with proper positioning

mechanically roll to expand ends as required

Curran International provides expert onsite installation of alloy tube ferrules with comprehensive quality control and minimal operational disruption.

Assess your specific wear patterns and process conditions to determine optimal ferrule placement and alloy requirements.

Select appropriate alloy based on corrosion resistance, temperature, and pressure requirements from our range of materials.

Expert installation using hydraulic expansion techniques with calibrated pressure settings for metal-to-metal contact.

Comprehensive QC procedures including dimensional verification and post-expansion inspections with detailed documentation.

01

Heat exchangers, condensers, coolers, reboilers, preheaters, and economizers experiencing tube-end erosion and corrosion can benefit from strategic ferrule placement.

02

Common materials include stainless steel, duplex, Inconel, CuNi, and C276, selected based on specific process conditions including corrosion resistance, temperature, and pressure requirements.

03

Installation timeline depends on scope and unit size. Our efficient onsite installation process with a small crew footprint minimizes downtime and allows for isolated unit work.

04

Tube ferrules provide an alternative to plugging by protecting critical wear zones, allowing tubes to remain in service and maintaining heat transfer capacity rather than losing it through plugging.

05

Our QC procedures include pre-expansion analysis, monitoring during expansion, post-expansion inspections, dimensional verification, and comprehensive documentation of all measurements and procedures.

Please enter your name and email. We’ll be in touch soon.