Reducing Fouling in Critical Crude and Hydrocarbon Services

Curran International leads the way in advanced exchanger coatings designed to reduce fouling and improve operational performance in high-temperature crude and hydrocarbon processing. By applying ultra-thin, high-performance coatings, Curran improves fluid “release” through exchanger tubes—minimizing fouling and supporting sustained heat transfer. Field trials also indicate improved product shear under normal operating conditions.

Hybrid Polymers and Inorganic Coatings

Curran’s coatings leverage hybrid polymers and inorganic components, enabling reliable performance across a wide range of operating conditions, including crude, coking, and hydrocarbon services up to 800ºF. Thin-film applications, often less than 50 microns, provide value-added protection without impacting thermal duty.

Flexible Applications for Different Exchanger Types

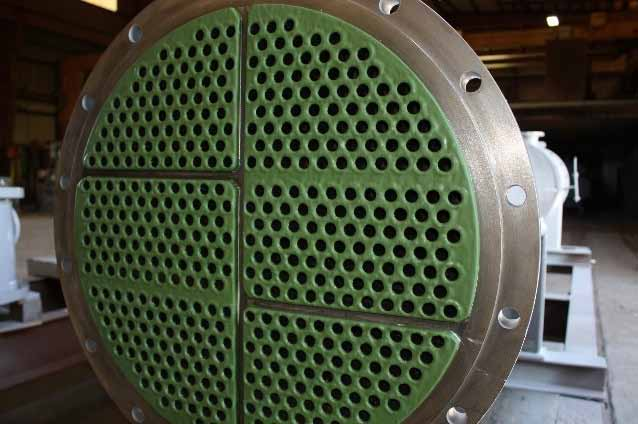

Curran has developed coatings for:

- Tube IDs – Full-length protection to reduce fouling in shell-and-tube exchangers.

- Tube ODs – For external surfaces in high-temperature services.

- Plate and Frame Exchangers – Anti-foul coatings that enhance release and reduce maintenance downtime.

Years of laboratory testing, combined with independent client trials, have validated the performance and longevity of these coatings in operational environments worldwide.

Client Performance Highlights

- FCC Bottoms / Slurry Exchanger (Crude >650ºF, ID Coating)

- Reduced fouling and lower head pressure, improving thermal duty by ~10%. Observed performance improvements sustained nearly a year after installation.

- Offshore Platform (Tube OD Coating, Light Hydrocarbon, 350ºF)

- Coated bundle ran uninterrupted for 240 days with no cleaning required; thin-film application had negligible effect on thermal performance.

- Asia Mid-Continent Refinery (Tube ID Coating, Crude 350ºF)

- Uncoated exchanger experienced severe fouling and dP increase. Since coating, 150 days of continuous operation with no dP rise.

- Power Plant Admiralty Brass Oil Coolers (Sea Water Service)

- Uncoated exchangers required monthly cleaning for barnacle and particulate buildup. Coated exchangers operated seven months uninterrupted, providing additional cooling capacity.

Why Curran Coatings Work

- Hydrophobic & Oleophobic Surface – Reduces product attachment and foulant nucleation.

- Thin-Film Application – Minimal impact on heat transfer and pressure drop.

- Field-Tested Reliability – Proven across multiple industries and climates.

- Maintenance Savings – Fewer cleaning events, lower downtime, extended service intervals.

Put Curran’s Coatings Portfolio to Work

Curran combines cutting-edge coating materials with expert application techniques to provide tailored anti-fouling solutions for heat exchangers across crude, hydrocarbon, and seawater services.

📩 Contact: Ed Curran – ecurran@curranintl.com

📞 Phone: 281.339.9993