Introduction

In the oil, gas, and petrochemical industries, fouling, scaling, and corrosion inside heat exchanger tubes are persistent challenges that compromise reliability, energy efficiency, and production output. Routine cleaning, maintenance downtime, and premature equipment degradation add significant costs to refinery operations.

To combat these issues, Curran International developed Curramix 3500, an advanced high-temperature inorganic coating engineered specifically for FCC slurry, crude, and hydrocarbon services. Designed as a thin-film barrier, Curramix 3500 reduces fouling, minimizes under-deposit corrosion, and improves operational efficiency, enabling refiners to extend run lengths and achieve measurable ROI.

This case study explores both laboratory test data and field-proven results from major U.S. refineries to demonstrate the performance of Curramix 3500 in real-world, high-stress environments.

What is Curramix 3500?

Curramix 3500 is a proprietary thin-film, high-temperature inorganic coating applied at 20–40 microns (0.4–1.7 mils, depending on application). Unlike traditional polymer or organic coatings, Curramix 3500 is designed to withstand extreme thermal and chemical environments commonly found in refinery heat exchangers, reactor effluent services, and crude units.

Key Benefits:

- Non-stick surface: Reduces surface tension, preventing hydrocarbon deposits, coking, and scale buildup.

- Thermal stability: Retains adhesion and repellency even after prolonged exposure to crude oil at 600°F (315°C).

- Corrosion protection: Shields base metal from high-chloride water, acids, and alkalis, preventing pitting and oxidation.

- Operational efficiency: Improves fluid flow, lowers backpressure, and extends the time between cleaning cycles.

Curramix 3500 coatings are applied following proper tube preparation (media blasting or grit blasting) to ensure adhesion and maximize long-term performance. Once applied, the coating provides a durable, high-performance surface engineered to extend exchanger service life and deliver measurable ROI.

Laboratory Evaluation: Performance Under Extreme Conditions

The objective of this laboratory evaluation was to validate Curramix 3500’s surface integrity, non-stick behavior, and corrosion resistance under extreme service conditions.

Testing protocols included:

- Hot crude immersion: Tube coupons coated with Curramix 3500 were submerged in 600°F (315°C) crude oil for six weeks.

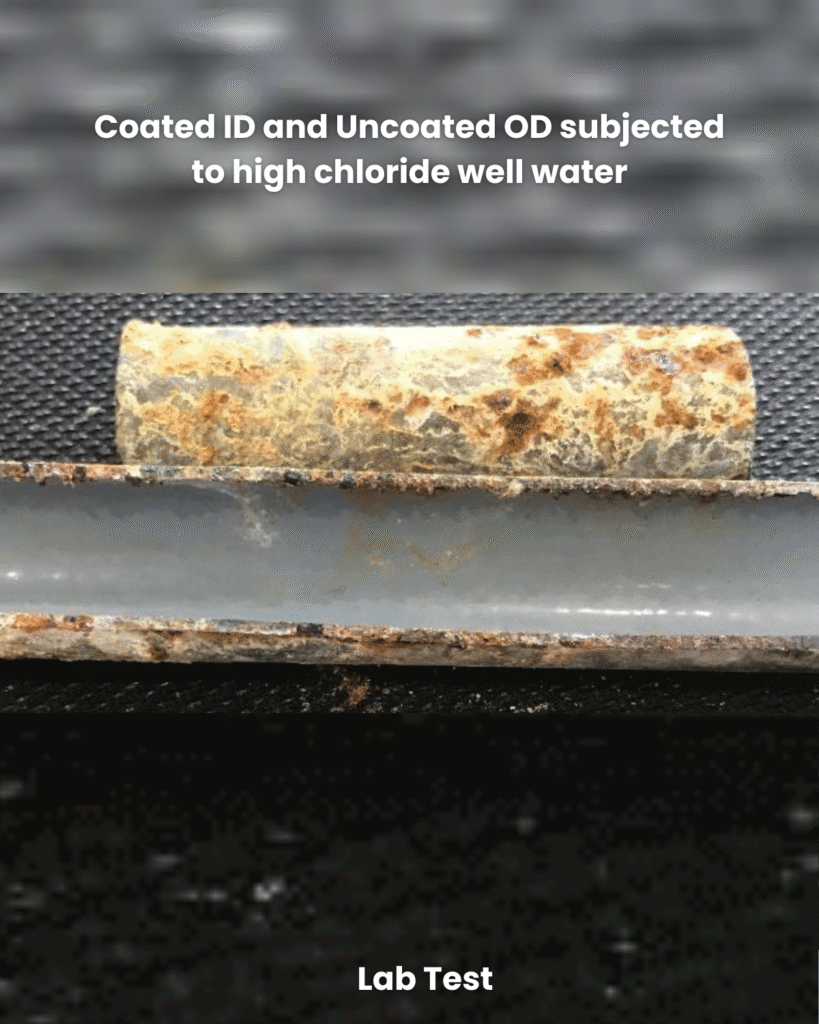

- High-mineral well water exposure: Coated samples were soaked in 700 PPM chloride-rich water at 203°F (95°C) for six weeks.

- Atlas Cell test: Samples were immersed in demineralized water for 60 days to measure blistering resistance and repellency.

- Acid and alkali resistance: Samples were exposed to 30% HCl and 50% NaOH solutions to test chemical durability.

Observations:

- Hot crude (600°F, 6 weeks): Coated IDs retained gloss and repellency with no adhesion loss.

- High-chloride water (95°C, 6 weeks): Coated tubes showed zero corrosion or deposition; uncoated surfaces scaled heavily.

- Atlas Cell (60 days): No blistering or loss of repellency.

- Chemical resistance: Coating continues to perform well under strong acid and alkali exposure.

Field Applications: Real-World Refinery Performance

Laboratory validation was followed by multi-year field evaluations at some of the largest refineries in North America. Curramix 3500 has consistently proven its ability to extend exchanger run lengths, reduce cleaning frequency, and deliver significant production and energy savings.

Super Major Beaumont Refinery – E-301/E-1365

- Service: Feed Preheat TRT3 – 345°F condensate

- Operating Conditions:

- OD fouling, 200–300°F kerosene (coated side)

- ID steam, 90–120°F

- Application: Curramix 3500 applied to tube ODs at 0.4–1.7 mils thickness

- Results:

- No cleaning events for 3+ years

- $1.5M/year production increase

- $300K/year maintenance savings

- $100K/year energy savings

Gulf Coast Refinery – Reactor Feed Effluent, 600°F

- Service: Alloy U-tube exchangers (321 SS, Cr-Mo)

- Application: Curramix 3500 applied to tube IDs

- Results: Significantly reduced tube fouling and improved operating stability

Texas Gulf Coast Refinery – Cooling Water Exchangers

- Service: Stainless steel exchangers in parallel service

- Results:

- Coated exchanger showed ~9% higher flow vs. uncoated

- Four months post-cleaning, coated exchanger delivered ~50% better performance compared to uncoated

Key Insights: From Lab to Plant

Exchanger Tubes – 6 weeks in 600°F crude. Minimal fouling.

Lab Results on Curramix 3500:

✓ No repellency loss after crude immersion

✓ No corrosion in high-chloride water

✓ Uncoated samples scaled and oxidized

Real-World Results:

- Super Major Texas Refinery: 3+ years, zero cleaning events → $1.5M production increase/year, $300K maintenance savings/year

- Super Major Gulf Coast Refinery: 600°F reactor effluent service → Significantly reduced fouling

- Gulf Coast Refinery: 9% improved flow vs. uncoated exchangers → 50% better performance after 4 months

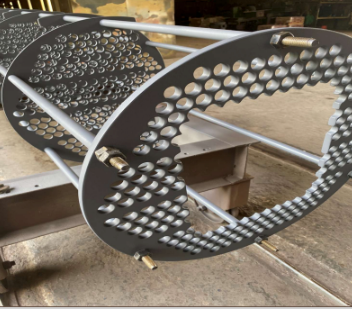

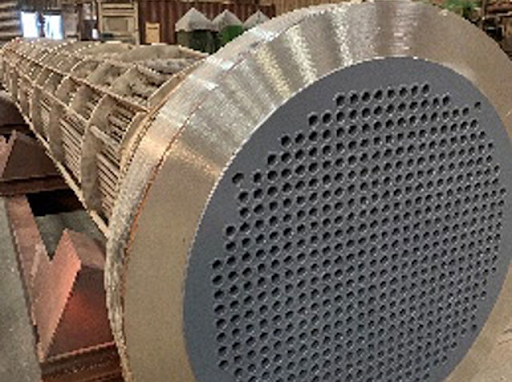

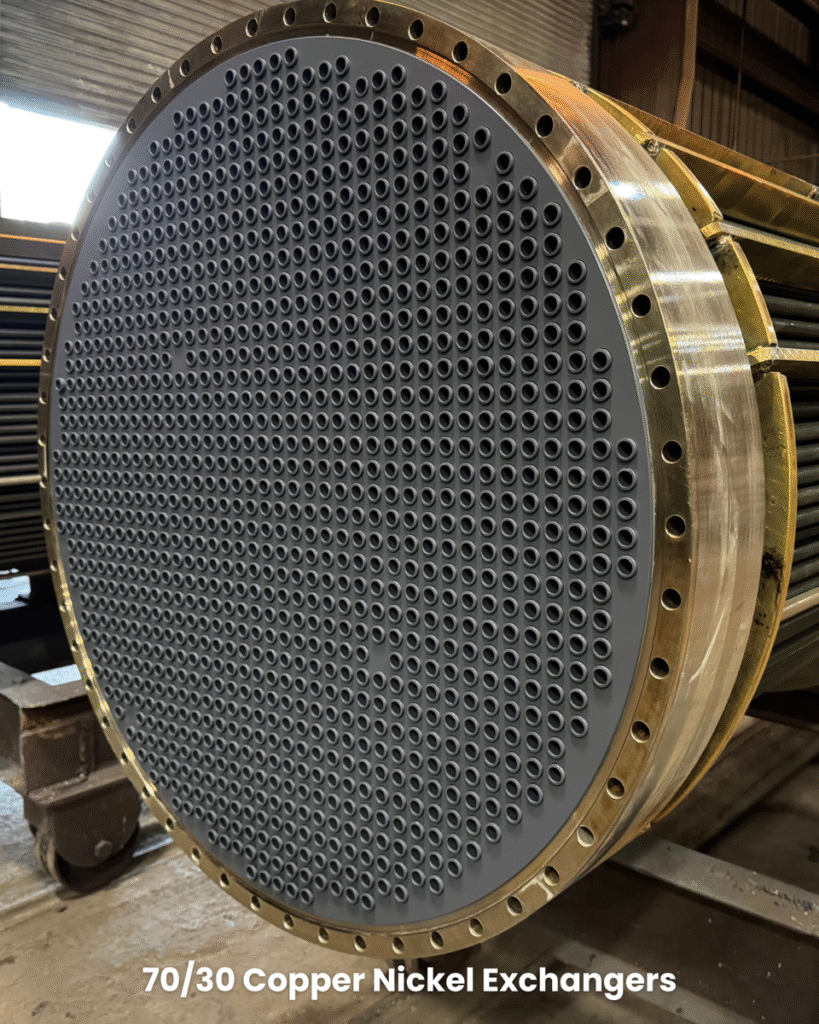

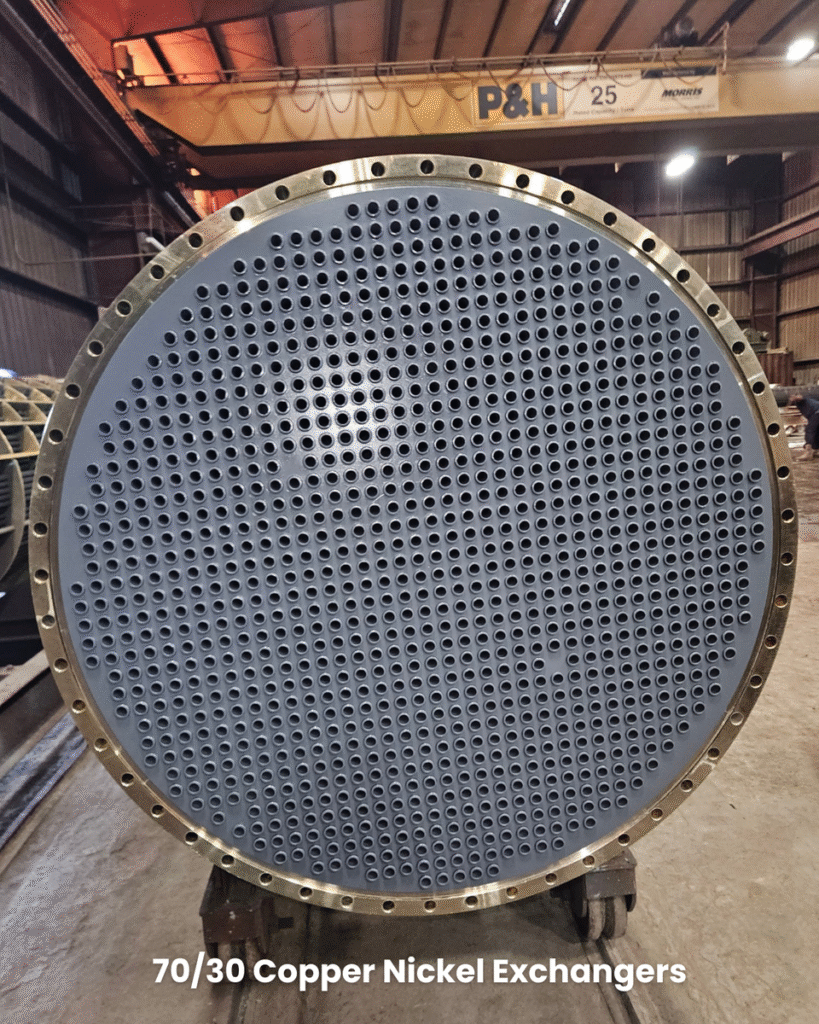

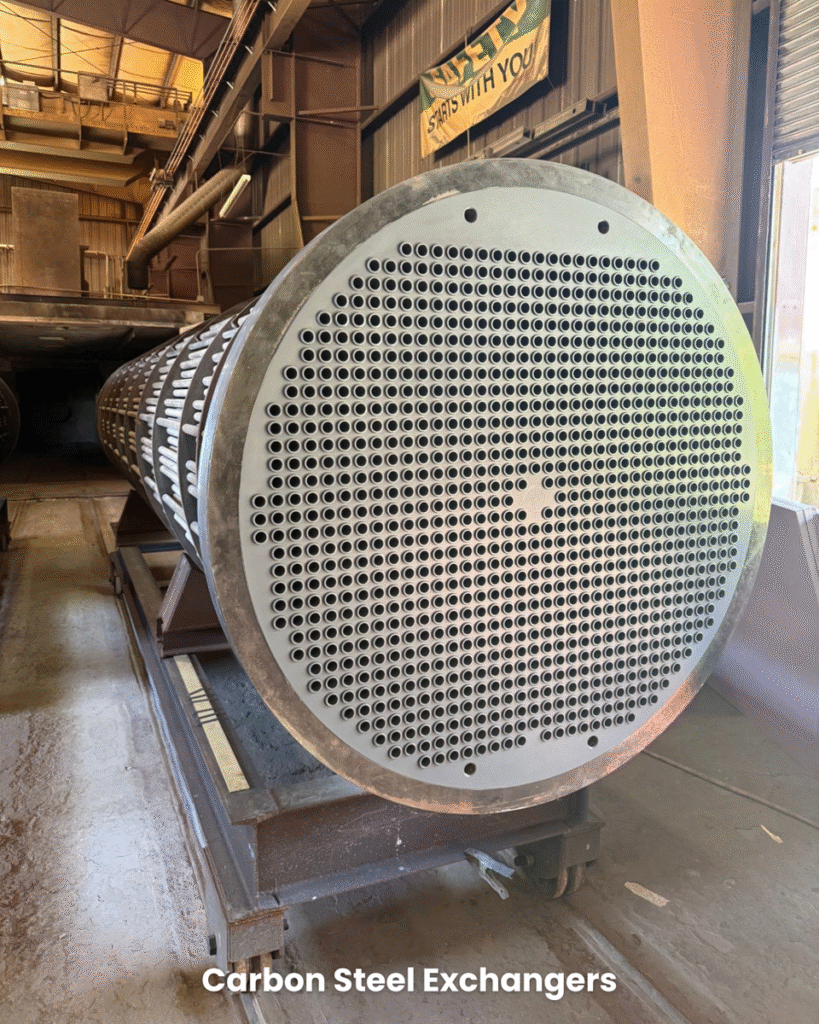

- Recent Installations: 4 carbon steel exchangers, 2 copper-nickel exchangers, and many more now operating with Curramix coatings

Curramix applications are creating big ROI for our clients.

What’s fouling costing your plant? 🔥

The combined lab and field evaluations confirm that Curramix 3500 delivers:

- Reliable non-stick surface performance in high-temperature crude service

- Protection against chloride-driven corrosion and scale deposition

- Excellent long-term adhesion and chemical resistance in harsh acidic/alkaline environments

- Significant reductions in maintenance costs and unplanned outages

- Tangible ROI through increased throughput, energy savings, and extended equipment life

Conclusion

Curramix 3500 is not just a protective barrier—it is a proven reliability strategy for refineries battling fouling, corrosion, and costly maintenance cycles. By combining advanced surface chemistry with proper tubular grit blasting preparation, refineries can achieve longer run lengths, lower operating costs, and improved unit performance.

Whether in FCC slurry, reactor effluent, or cooling water exchangers, Curramix 3500 has shown exceptional durability and measurable financial return for some of the largest refineries in the U.S.

Contact Us

Are you ready to reduce fouling, extend run lengths, and capture millions in production and energy savings?

Contact Curran International today to request a free consultation and learn more about the Curramix 3500 application process and performance data.

For more information about Curramix 3500 heat exchanger coatings, contact Edward L. Curran at ecurran@curranintl.com.