Stop accepting short-lived coatings as “normal.”

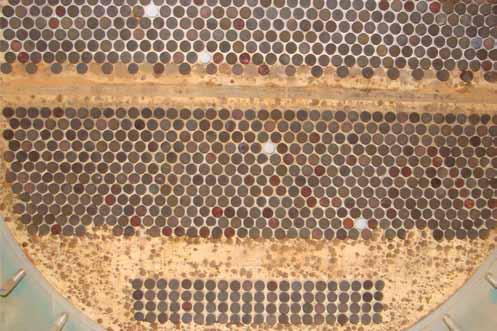

Unplanned maintenance during an outage is expensive—especially when it’s the direct result of coating failure. Coating blisters, delamination, oxidation, and under-deposit pitting can threaten plant integrity and shorten the life of critical assets.

At Curran International, we believe coatings should survive multiple turnarounds, not fail after the first.

Why Coatings Fail

Even the best coating formula can fail if it’s:

- Mismatched to operating conditions – Exceeding the coating’s temperature, chemical, or pressure limits.

- Applied over poor surface prep – Contaminants or insufficient anchor profile prevent adhesion.

- Put into service too soon – Many epoxies need 5+ days to fully cure at 70°F, even if tack-free within hours.

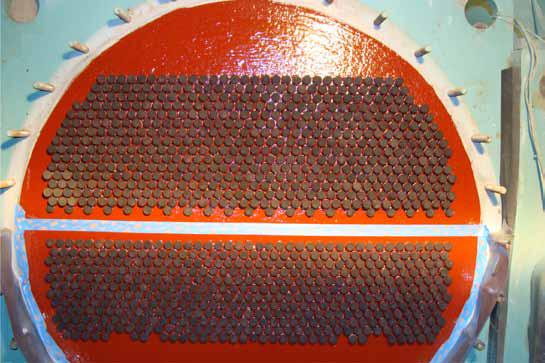

How Curran Coatings Last Longer

- Correct Selection – We match the coating to every operating and maintenance condition, including online steam cycling and chemical cleaning.

- Flawless Surface Prep – Achieving NACE 1 white metal blast cleanliness, verified contaminant removal, and proper anchor profile.

- Proper Curing – Ensuring coatings are fully polymerized before immersion service.

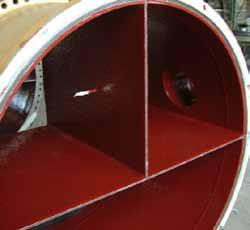

Proven Products for Demanding Environments

- Curran 500 – Versatile 100% solids epoxy for all power plant and chiller cooling water systems. Can be trowel-applied, sprayed, brushed, or rolled.

- Curran 1000R – High-temp novolac epoxy for immersion service up to 365°F (steam excursions to 400°F). Ideal for exchanger tube sheets.

- Curran 1200 – Spray-applied novolac epoxy for tanks, vessels, and high-volume coating needs. Single coat to 20–24 mils.

- Curran 1500 – Hybrid novolac epoxy for cold wall services and uninsulated vessels. Machinable after cure; tested at 365°F.

Field-Proven Around the World

Curran’s high-functionality 100% solids novolac and hybrid coatings have been protecting critical cooling water services for years—backed by global client references. Whether in the shop or field, our experts ensure coatings are applied and cured for maximum life.

to augment the use of anodes in corrosive cooling water service.

Channel coating selection should consider cold wall risk, and

exposure to high temperature excersions and steam out.

Protect your investment with coatings designed to last—turnaround after turnaround.

📞 (281) 339-9993

📧 US Domestic: edeely@curranintl.com

📧 International: abarre@curranintl.com