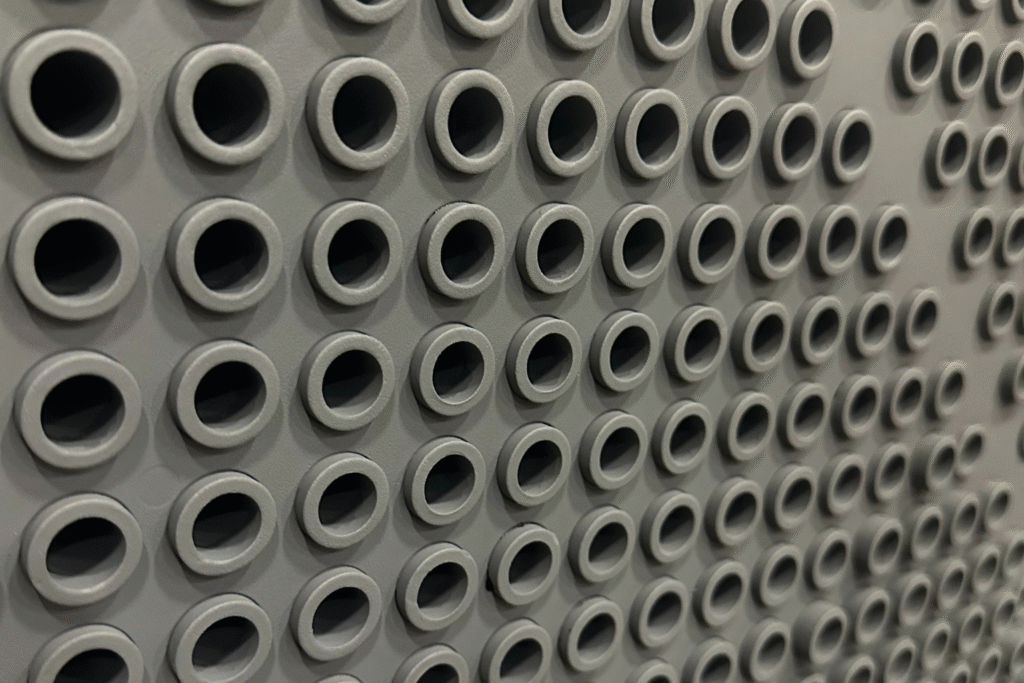

Condenser Tube Repairs involve the installation of thin-walled tube liners and inserts to protect against erosion and corrosion on the ID or OD of air fin exchanger tubes near the tubesheet. Our ferrules are rolled both into the tubesheet and parent tube to provide protection and mitigation for thin areas due to localized erosion and corrosion. If no other degradation mechanisms exist, installation of tube liners can return tube ends to like-new condition.

Industrial condensers face persistent tube end failures from localized erosion and corrosion near tubesheets. Traditional plugging reduces heat duty and accelerates erosion in remaining tubes.

Typical Industry Response:

Tube plugging and equipment replacement

Typical replacement costs

Condenser Tube Repairs provide targeted protection through hydraulically expanded tube liners and inserts. Field installation eliminates shop work requirements.

Specialized Metallurgy:

Stainless steel, duplex, Inconel, CuNi, C276 options

Thin-walled liner thickness

Condenser tube repairs preserve full tube count and heat duty by repairing compromised tubes instead of plugging them. Field installation reduces turnaround time by eliminating equipment removal and shop work.

These repairs can upgrade materials to corrosion-resistant alloys, prevent erosion acceleration, and restore tube ends to like-new condition while maintaining optimal flow characteristics.

Preserve tube count and heat duty by repairing rather than plugging compromised tubes

Field installation eliminates equipment removal and shop work requirements

Upgrade from carbon steel to specialized alloys including stainless steel, Inconel, and C276

Prevent velocity increases that occur when tubes are plugged

Return tube ends to like-new condition when no other degradation mechanisms exist

Thin-walled design (0.028″ to 0.035″) maintains flow characteristics

Request field services support and technical documentation

Onsite measurement and go-no-go liner testing with Curran personnel

Professional installation with hydraulic expansion and rolling

Quality control inspection and nitrogen leak testing

01

Air fin exchangers, heat exchangers, steam condensers, and process condensers experiencing tube end thinning within 3' to 5' of the tubesheet can benefit from tube liner installation.

02

Installation timing depends on tube count and site conditions. Field installation eliminates equipment removal requirements, reducing overall turnaround duration compared to shop-based solutions.

03

Tube repairs avoid the costs associated with plugging (reduced heat duty), complete re-tubing, or equipment replacement while maintaining full heat transfer capacity.

04

Various alloys including stainless steel, duplex, Inconel, CuNi, and C276 are available to provide corrosion resistance superior to carbon steel parent tubes.

05

Curran uses proprietary sizing techniques and provides Go-No-Go liners and collar samples for field testing. Professional installation includes hydraulic expansion and rolling at both tubesheet and trailing edge.

Please enter your name and email. We’ll be in touch soon.