Objectives

Repeat of Study 1, but it assumes anti-fouling coating on both tube OD & ID.

This study evaluates a Crude preheat exchanger service heat transfer performance with the following tube material and coatings and estimates the energy savings and CO2 Emissions Reduction:

- Carbon Steel

- Stainless Steel

- Carbon Steel Tube ID & OD Coated

- Stainless Steel Tube ID & OD Coated

Assumptions

- Service – Desalted Crude vs Resid

- Tube ID Coating Thickness – 25 Microns (0.001 inch)

- Tube OD Coating Thickness – 25 Microns (0.001 inch)

- Coating Thermal Conductivity – 0.722 Btu/hr-ft-F

- Fuel Value -$3.50 per MBtu/hr

[Note fuel prices in Asia can be 3X compared to US] - Furnace Efficiency = 0.9

- Network Factor = 0.85

[Part of the Duty Gain in the Exchanger Diminishes Heat Transfer on other Exchangers in the Preheat Train due to changes in temperature differentials] - CO2 Reduction based on EPA Conversion Equations

- Heat Transfer Calculation performed with HTRI XIST

- Assumed Fouling Factor shown in the Comparison Tables below

- All bundles are cleaned yearly

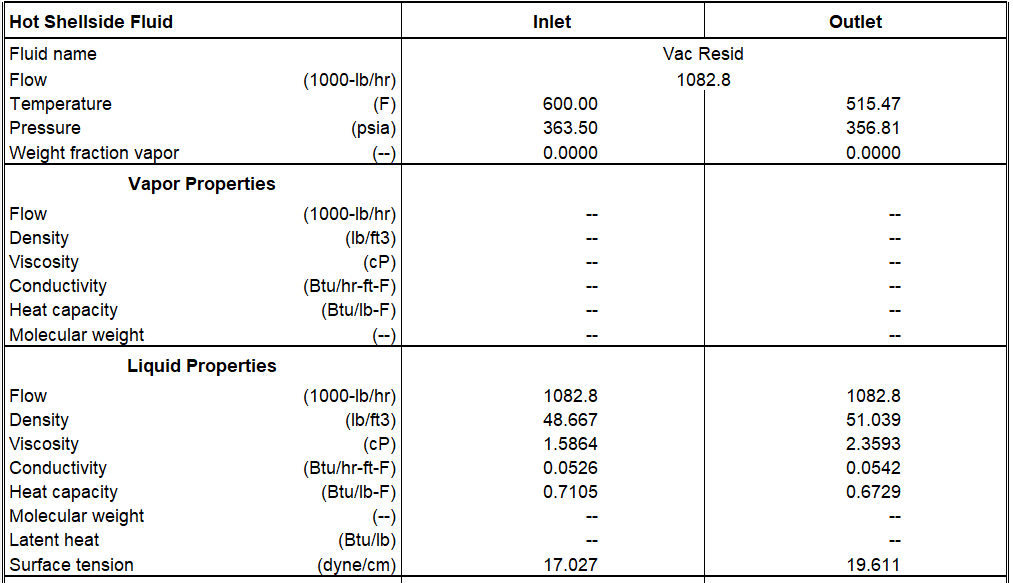

- Assumed Inlet Operating

- Crude Inlet Temp – 400 F

- Crude Rate – 1800 klb/hr

- Resid Inlet Temp – 600 F

- Resid Rate – 1,082 klb/hr

Heat Exchanger Geometry

- TEMA – AES

- Shell Id = 54”

- 1130 Tubes

- 1” Tube OD

- 0.083” tube wall thickness

- 2 Tube Passes

- 20 ft length

- 11 Baffle Cross Passes, Single Vert Seg , 18.8% Cut

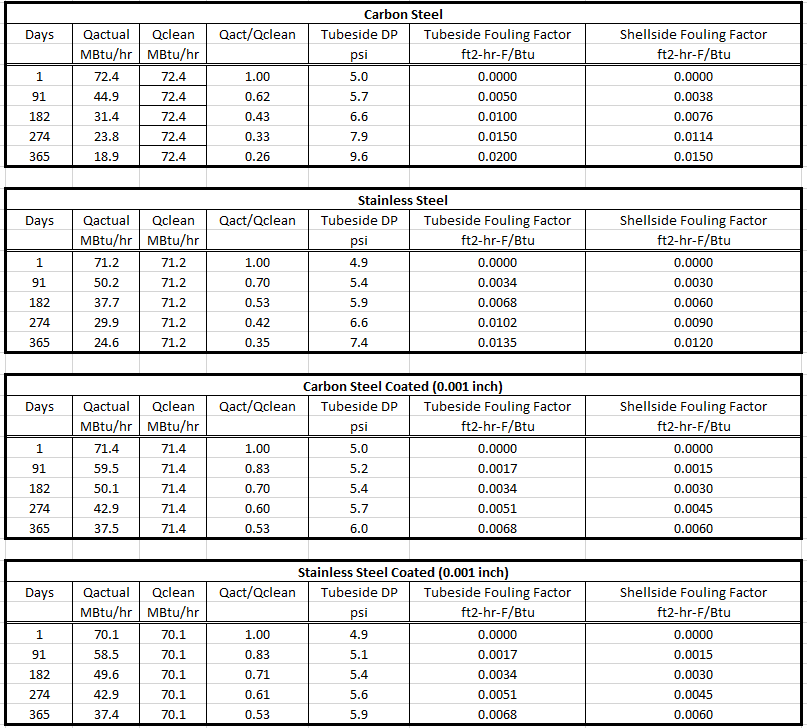

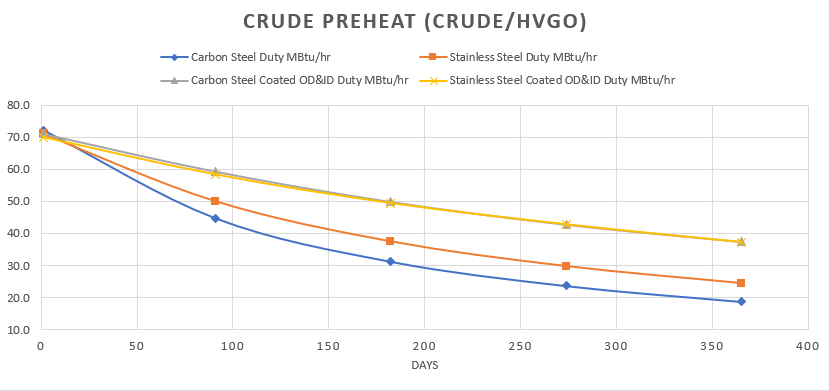

Results

Comparison Tables

Economic & CO2 Reduction Benefit

Coated Versus Carbon Steel

- Annualized Duty Reduction = 14 MBtu/hr

- Energy benefit = $405k a year

- CO2 Equivalent Benefit = 6,131 Tons over 2 years

Coated Versus Stainless Steel

- Annualized Duty Reduction = 9 MBtu/hr

- Energy benefit = $260k a year

- CO2 Equivalent Increase Emissions = 3,937 Tons a year

Note if the Crude preheat furnace is limited and/or the Preheat Train is Hydraulically limited, the margin benefits could be significantly more than the credits listed above.