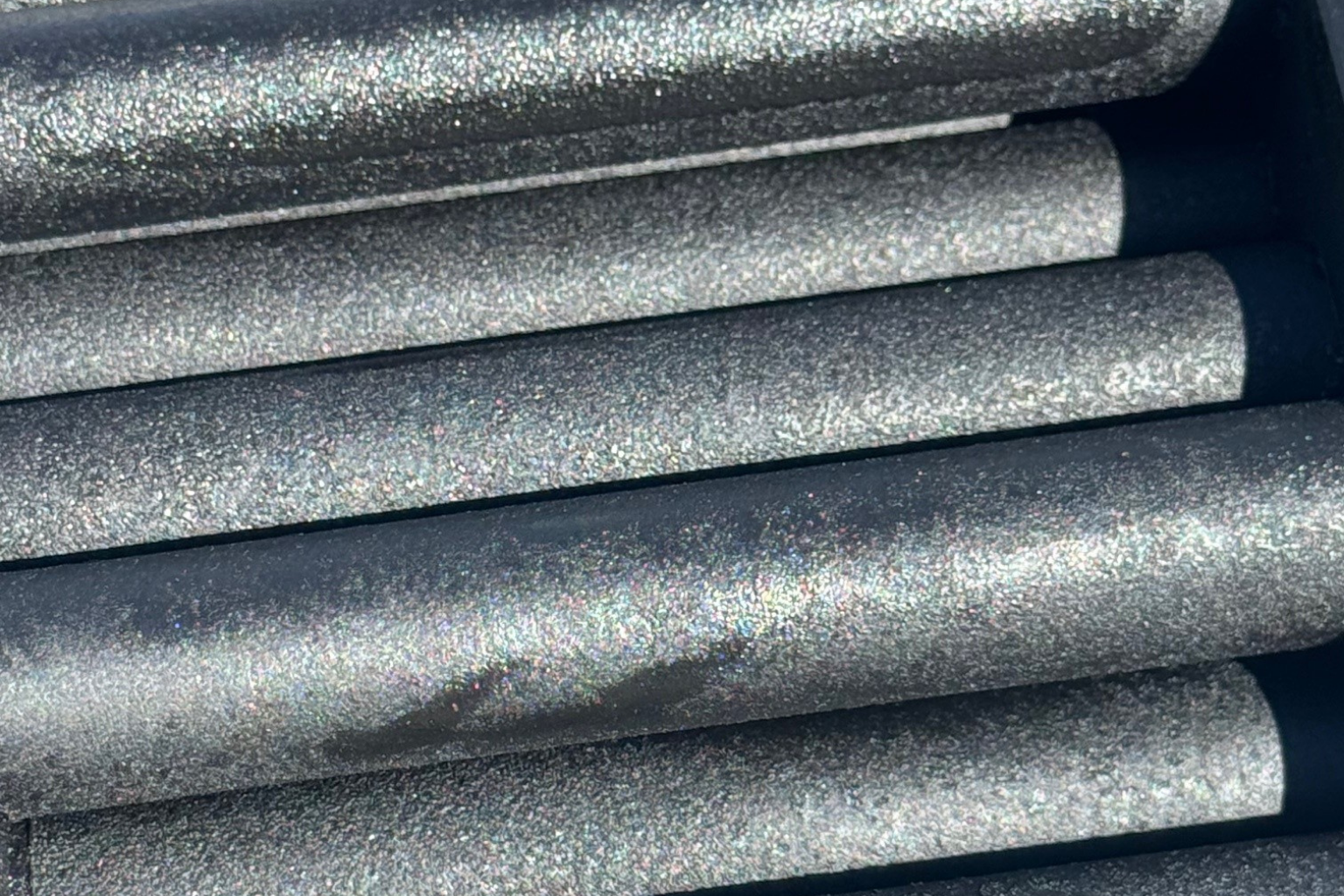

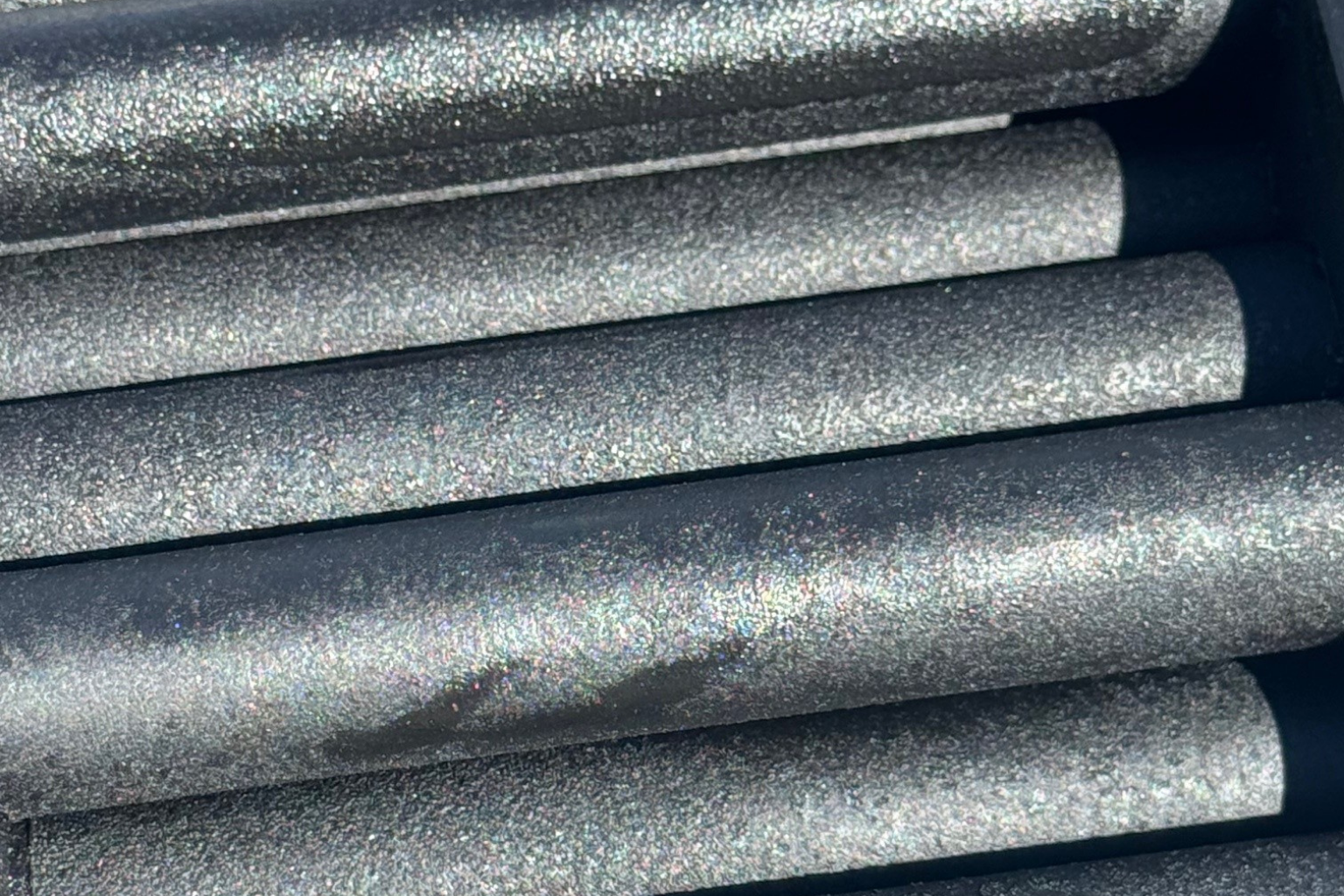

Curran’s fouling-mitigation solutions for crude preheat exchangers are engineered to reduce deposit adhesion on the exchanger substrate. We offer a range of high-performance coatings, including ceramics and other advanced formulations, built for the extreme temperatures of crude service and applicable on both the tube side and shell side.

Featuring low surface energy and low polarity, these hydrophobic and oleophobic barriers limit coke precursor buildup and other foulants, helping maintain heat transfer efficiency, extend run lengths, and reduce the frequency of mechanical cleanings.

Crude preheat trains experience notorious fouling and require as frequent cleanings, eventually leading to a performance degradation and rate cuts.

Routine Cleaning Required by Traditional Systems

Curran’s advanced coatings create ultra low-surface-energy surfaces that prevent foulant adhesion at the molecular level

Intervals Between Cleanings for Coated Systems

Curran’s anti-fouling technology dramatically reduces fouling rates by 50–80%, extending cleaning intervals from just 3–4 months to over 24 months in many cases.

This improves heat recovery, lowers furnace fuel use by up to 15 MMBtu/hr, and saves thousands in daily energy costs—often paying for itself in under 95 days.

By minimizing cleanings and preventing unplanned shutdowns, it enhances reliability, throughput, and environmental compliance across your crude unit.

Field data demonstrates 50–80% decreases in fouling accumulation on treated crude preheat exchangers, maintaining cleaner surfaces for extended periods

Advanced coatings extend cleaning intervals by orders of magnitude – from 3-4 months to 24+ months without hydroblasting or maintenance

Better heat recovery reduces furnace duty by 10-15 MMBtu/hr, saving $2,000-$3,100 per day in fuel costs while reducing CO₂ emissions

Fewer cleanings eliminate bundle replacement costs and lost production, with coating investments recovered in under 95 days through energy savings alone

Stabilized heat recovery enables higher throughput for longer campaigns while reducing unplanned rate cuts or shutdowns due to fouling

Reduced frequency of hazardous cleaning operations and chemical waste disposal, with environmentally compliant coating formulations

Evaluate fouling issues, operating conditions, and metallurgy to recommend optimal anti-fouling solution

Patented tubular grit-blasting technology achieves white metal (SSPC-SP10) condition with optimal anchor profile

Proprietary application methods ensure uniform coverage using specialized spray wands for tube IDs and conventional techniques for ODs

Controlled curing process with comprehensive QC including adhesion tests, thickness verification, and surface analysis

Reinstall treated components without design changes—ultra-thin coating ensures fit and function remain intact.

Track performance with post-installation fouling analysis and receive ongoing technical support for maintenance and cleaning.

Curran International’s 40+ years of coating expertise and global facility network ensure turnkey solutions that integrate seamlessly with your turnaround schedules.

Our engineers evaluate your fouling challenges and recommend optimal coating specifications

Custom application plan coordinated with your turnaround schedule and maintenance windows

Expert technicians apply coatings using proprietary methods at our global facilities

Ongoing technical support and performance monitoring to maximize coating effectiveness

01

Advanced coatings are designed for multi-year service, typically lasting 7–10 years before renewal consideration. Many exchangers remain in service 5+ years with no recoat needed, with surface treatments maintaining effectiveness after 4+ years of operation.

02

Results vary by application, but commonly show fouling rate reductions of 50% or more. Field data demonstrates 20–80% lower fouling factors compared to uncoated service, with some systems effectively mitigating frequent fouling cycles.

03

Cleaning frequency is dramatically reduced. When required, standard high-pressure water jetting (up to 20,000 psi) can be used, with deposits removing more easily due to non-stick surfaces. Water rinses or mild chemical flushes are typically sufficient for maintenance.

04

No measurable negative impact occurs. Treatments are ultra-thin with negligible thermal resistance. Field trials show no negative effect on heat-transfer performance, with many sites reporting higher average coefficients due to sustained cleanliness.

05

Yes, most coating technologies can be applied to used equipment. Advanced ceramic coatings are routinely applied to existing bundles during turnarounds after thorough surface preparation. Specialized surface treatments may require specific processing conditions.

Please enter your name and email. We’ll be in touch soon.