Objectives 2A:

This study evaluates a Crude preheat exchanger service heat transfer performance with the following tube material and coatings and estimates the energy savings and CO2 Emissions Reduction:

- Carbon Steel

- Stainless Steel

- Carbon Steel Tube ID Coated

- Stainless Steel Tube ID Coated

Assumptions

- Service – Desalted Crude vs Heavy Vacuum Gas Oil (HVGO)

- Tube ID Coating Thickness – 25 Microns (0.001 inch)

- Coating Thermal Conductivity – 0.722 Btu/hr-ft-F

- Fuel Value -$3.50 per MBtu/hr

[Note fuel prices in Asia can be 3X compared to US] - Furnace Efficiency = 0.9

- Network Factor = 0.75

[Part of the Duty Gain in the Exchanger Diminishes Heat Transfer on other Exchangers in the Preheat Train due to changes in temperature differentials] - CO2 Reduction based on EPA Conversion Equations

- Heat Transfer Calculation performed with HTRI XIST

- Assumed Fouling Factor shown in the Comparison Tables below

- Coated bundles are cleaned at 2 year frequency

- Non coated bundles are cleaned yearly

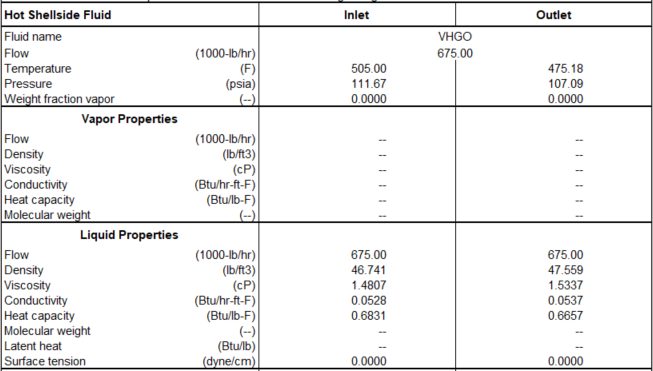

- Assumed Inlet Operating

- Crude Inlet Temp – 370 F

- Crude Rate – 650 klb/hr

- HVGO Inlet Temp – 505 F

- HVGO Rate – 675 klb/hr

- 7 Days Oil Out to Oil In for Exchanger Cleaning

- Maintenance Cost for Cleaning – $40k

- Margin Cost Per Day During Cleaning – Approx $15k per day

Heat Exchanger Geometry

- TEMA – AES

- Shell Id = 50”

- 1054 Tubes

- 1” Tube OD

- 083” tube wall thickness

- 4 Tube Passes

- 20 ft length

- 11 Baffle Cross Passes, Single Vert Seg , 20.9% Cut

Results

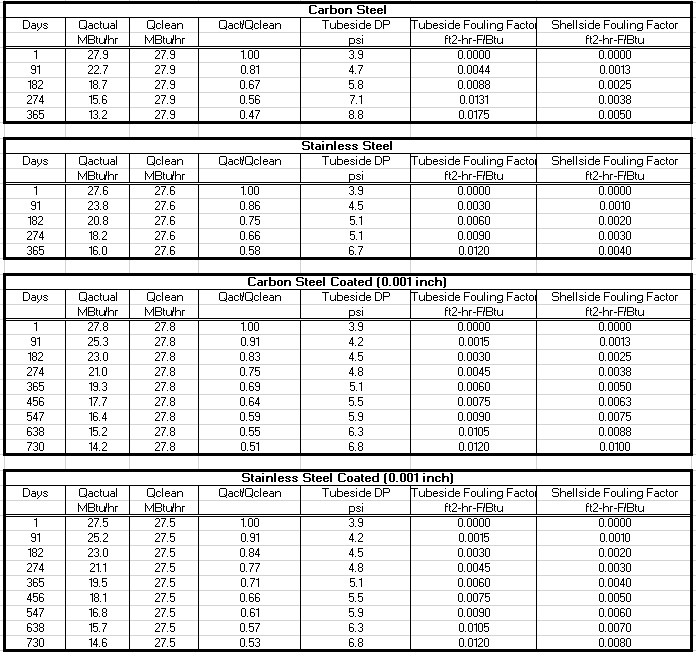

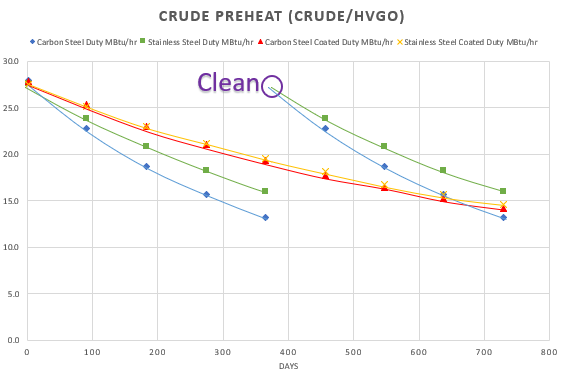

Comparison Tables

Economic & CO2 Reduction Benefit

Coated Carbon Steel (cleaned 2yr interval) Versus Carbon Steel (cleaned yearly)

- Annualized Duty Reduction = 0.6 MBtu/hr

- Energy benefit = $28k over 2 years

- Margin + Maintenance benefit from increasing cleaning interval = $105k+$40k=$145k

- CO2 Equivalent Benefit = 423 Tons over 2 years

- Overall Benefit = $28k + $145 k = $173k

Coated Stainless Steel Versus Stainless Steel

- Annualized Duty Reduction = -0.9 MBtu/hr

- Energy benefit = -$46.8k over 2 years

- Margin + Maintenance benefit from increasing cleaning interval = $96.8k+$40k=$136.7k

- CO2 Equivalent Increase Emissions = 708 Tons over 2 years

- Overall Benefit = -$46.8k + $136.7k = $89.9k