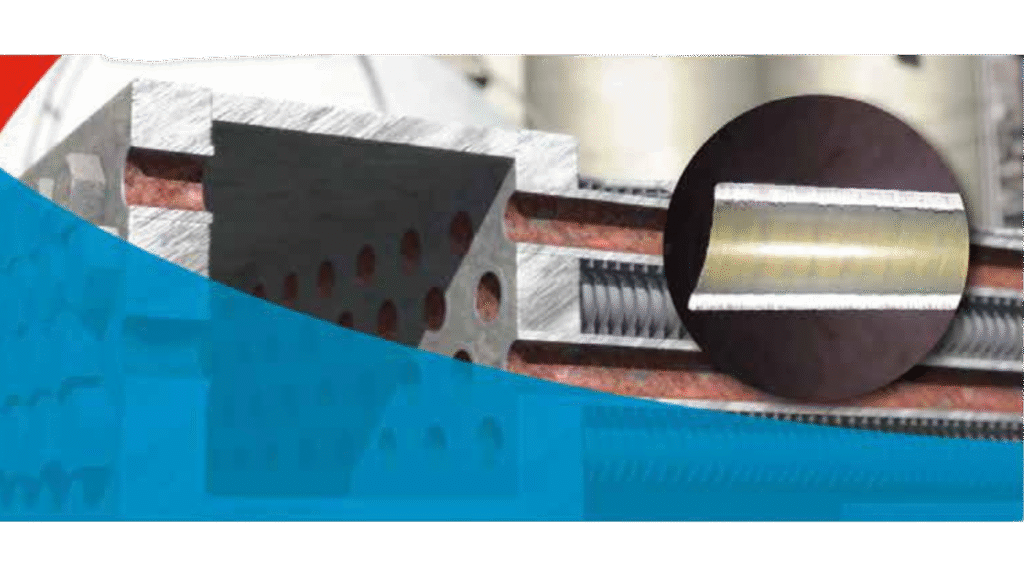

Curran International has unveiled a breakthrough in heat exchanger fouling prevention—Curramix 2500, an ultra-thin, high temperature inorganic coating designed for demanding hydrocarbon and coking service environments. This next-generation coating made its debut at NACE Corrosion 2017 and is already showing exceptional performance in field and laboratory testing.

A New Era in Tube ID Coating Technology

Unlike conventional polymer tube ID coatings used for cooling water applications, Curramix 2500 is inorganic, making it ideal for refinery hydrocarbon services far beyond the temperature limits of traditional coatings.

- Temperature resistance: Retains lubricity up to 1200°F (649°C)

- Application thickness: 25 microns DFT in just one to two coats

- Proven results: Lab-tested in a crude test loop at 700°F (371°C)

The coating’s oleophobic properties mean it cannot be wetted by oils or inks, making it perfectly suited for non-aqueous services such as:

- Pre-crude heaters

- Ethylene transfer line exchangers (TLEs)

Operational Benefits for Refineries

Fouling in crude distillation units directly impacts energy consumption and operational efficiency. By reducing fouling and coking, Curramix 2500 helps refineries:

- Extend run times between maintenance shutdowns

- Improve heat transfer performance

- Lower operational energy costs

- Reduce unplanned outages

Ed Curran, CEO of Curran International, noted: “Our refinery partners have seen promising results. The ability of Curramix 2500 to improve process-critical exchanger efficiency is generating significant interest.”

Tested in Real-World Conditions

Field tests are underway, including installations in:

- A refinery crude coker unit

- Gas service applications

- An exchanger subject to alloy scaling downstream of a catalyst reactor

These tests build on Curran’s proven track record with other thin film coatings such as Curran 1000T, PFA, ETFE fluoropolymers, and baked phenolic coatings applied at 200–250 microns for corrosion and fouling protection.

Proven Expertise in Global Coating Applications

Curran International coatings are in service worldwide, protecting heat exchanger tubes from corrosion, scaling, and fouling in some of the harshest industrial environments. With the launch of Curramix 2500, Curran continues to set new performance benchmarks in ultra-thin, high-performance coating solutions.

Contact Curran International to discuss a trial application of Curramix 2500 and learn how it can improve the efficiency and lifespan of your process-critical exchangers.

📧 Ed Deely – edeely@curranintl.com

📞 +1 281-339-9993