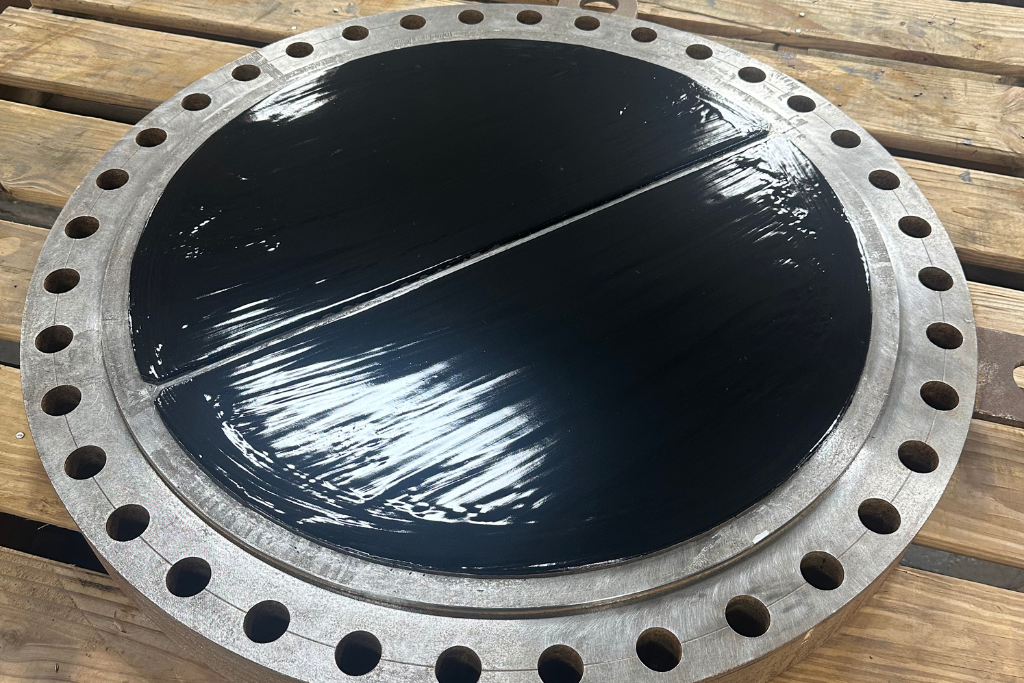

Curran 1500 exhibits broad chemical resistance suitable for refinery and plant services. It is recommended for water (including salt and cooling water), hydrocarbons, steam, many acids, and caustics. For example, it holds up well in sour water strippers, amine units, crude oil, brine, and moderate concentrations of sulfuric or caustic. It's generally not attacked by petroleum products or common process chemicals. For extremely aggressive acids (strong sulfuric, HF, etc.) or high concentrations, it's best to consult with Curran for specific compatibility – but in most cases, Curran 1500 will handle the typical corrosion agents found in process streams.