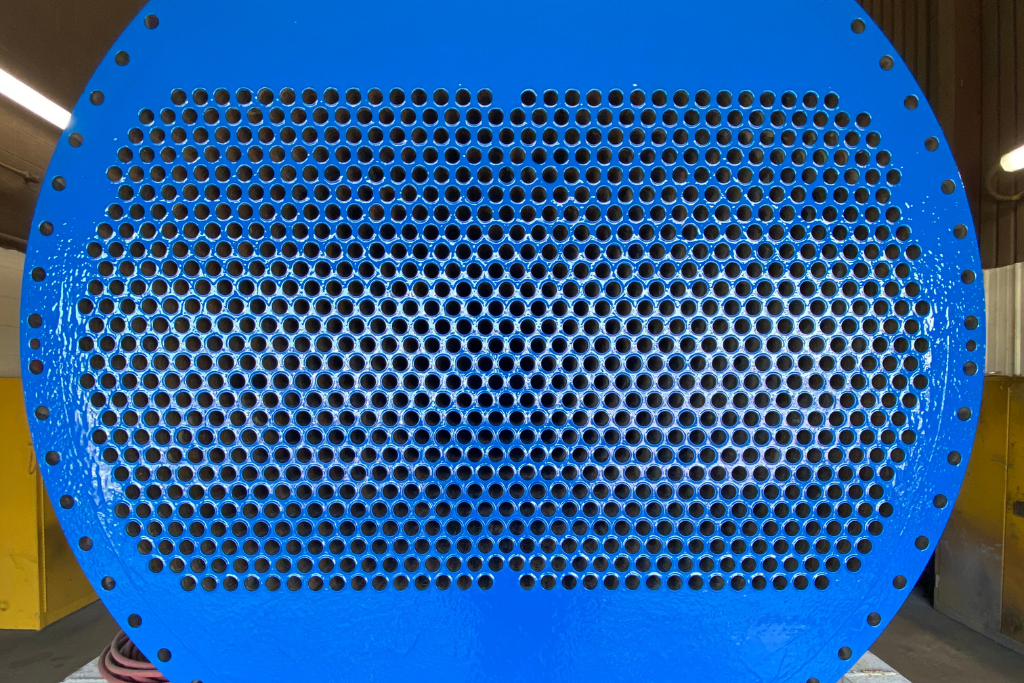

Curran 500 is an advanced two-part, 100% solids epoxy coating formulated for immersed service in harsh industrial environments. This high-build coating can be applied in a single, thick layer to repair and protect steel surfaces exposed to water or hydrocarbons.

Once cured, Curran 500 creates a durable barrier with exceptional corrosion resistance and foul-release properties, ideal for mitigating both rust and fouling deposits on metal equipment. With zero volatile organic compounds (VOC) and a high-gloss finish, Curran 500 provides a smooth surface that reduces fluid drag while protecting critical assets.

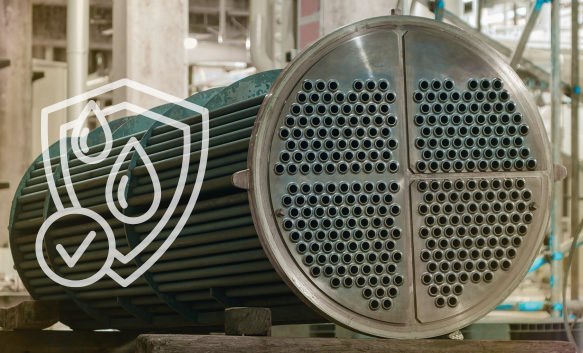

Water-side equipment faces relentless attack from corrosion and fouling in cooling water systems. Traditional coatings often fail prematurely due to poor adhesion, water permeability, or inability to withstand thermal cycling.

Typical uncoated equipment life

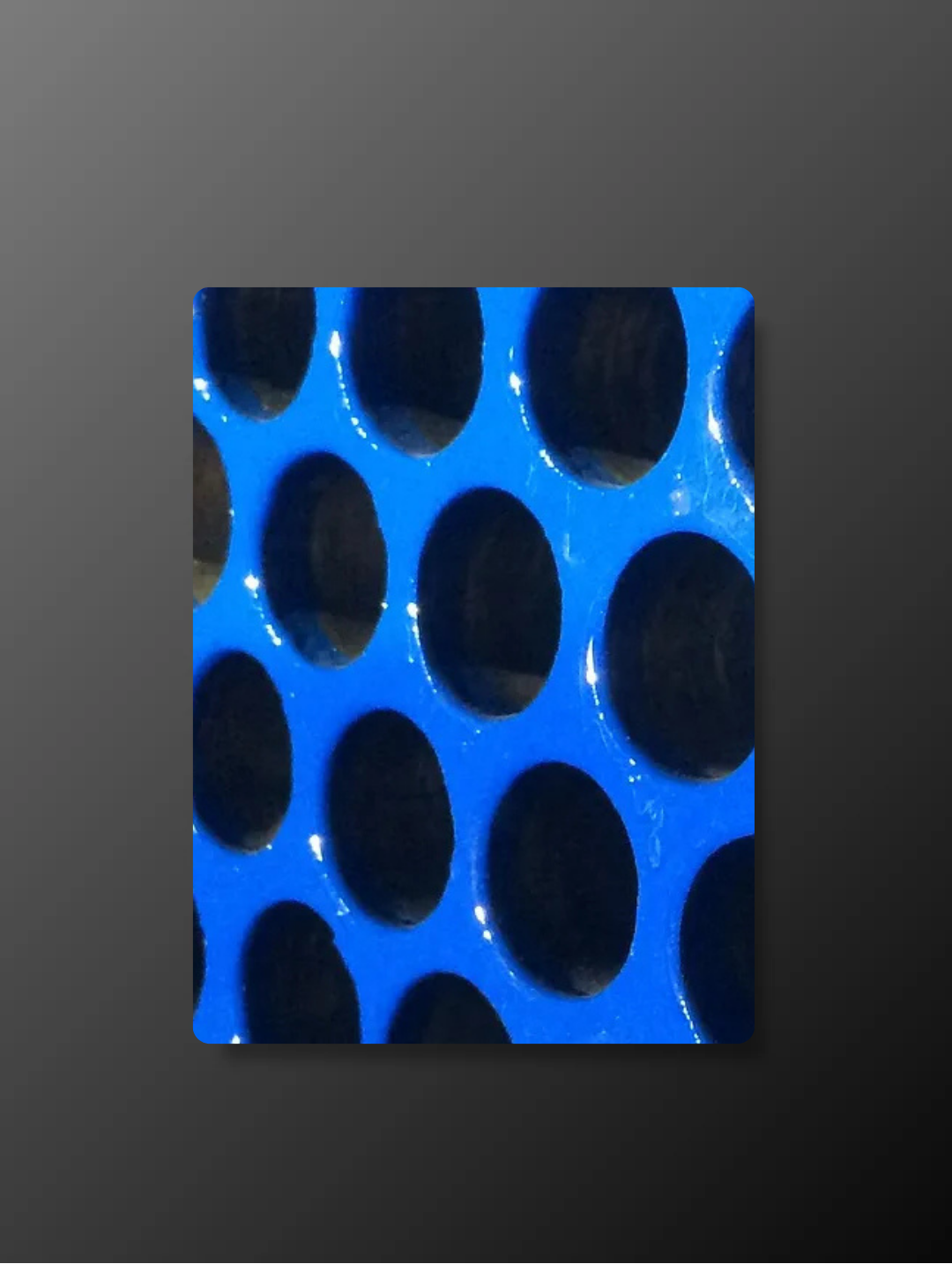

Curran 500’s 100% solids epoxy formulation bonds tenaciously to steel substrates with ~3,800 psi adhesion strength. The coating’s ultra-smooth finish and foul-release properties significantly reduce deposit accumulation.

Adhesion strength with Curran 500

Proven to add 10+ years of operational life to chiller tube sheets and water boxes by preventing corrosion penetration

High-gloss finish impedes attachment of mineral scale, biological growth, and debris, maintaining cleaner surfaces longer

Tested through 20 cycles from 212°F to 32°F with no loss of adhesion or coating integrity

100% solids formulation allows thick-build application in one or two coats, reducing labor time and complexity

Smooth surface reduces fluid drag and maintains heat transfer coefficients between cleaning cycles

Withstands exposure to cooling water chemistries and hydrocarbons across pH 2-13 at ambient conditions

180°F (82°C) continuous immersion

Brush or roller

10+ years proven field performance

Withstands repeated thermal cycling

Tack-free in 5-7 hours, full immersion after 24 hours

Carbon steel, properly prepared

pH 2-13 fluids, hydrocarbons

30-40 mils DFT recommended

Proven performance in refineries, power plants, and chemical facilities worldwide

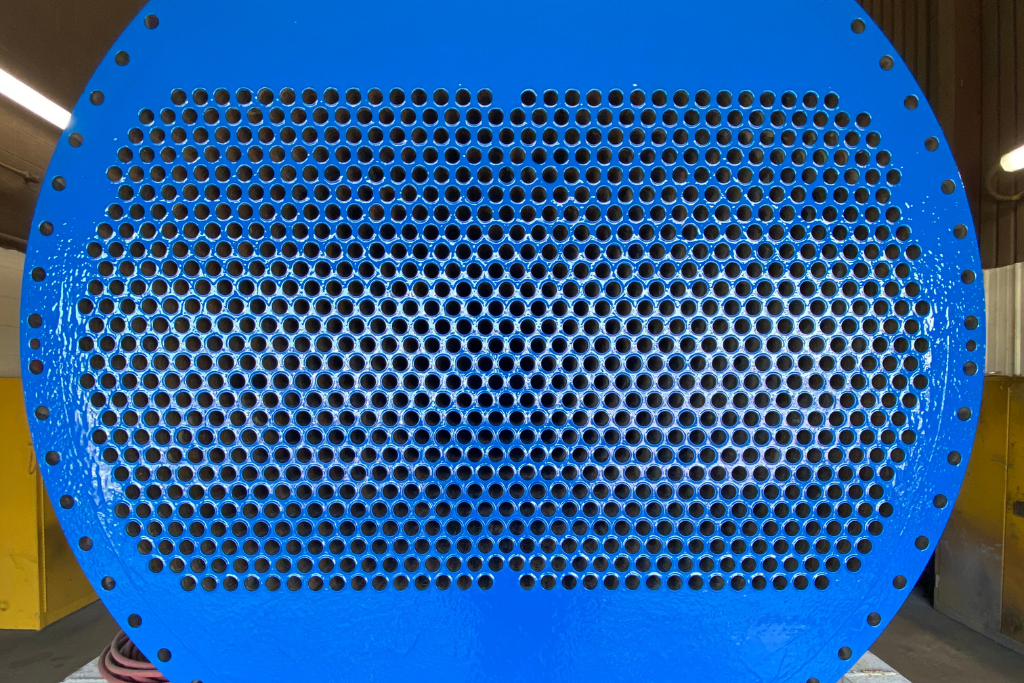

| Equipment | Chiller tube sheets in fin-fan coolers |

| Challenge | Severe crevice corrosion at tube-to-tubesheet joints |

| Solution | Curran 500 applied at 35 mils DFT to waterside |

| Results |

|

| Equipment | Water box interiors and piping |

| Challenge | Continuous water exposure causing metal loss |

| Solution | Curran 500 coating of all wetted surfaces |

| Results |

|

| Equipment | Firewater and seawater piping systems |

| Challenge | Saltwater-induced corrosion |

| Solution | Internal lining with Curran 500 |

| Results |

|

| Equipment | Channel heads in hydrocarbon service |

| Challenge | High humidity and vapor-induced corrosion |

| Solution | Curran 500 application to channel covers |

| Results | Eliminated recurring erosion and pitting |

Proven performance in refineries, power plants, and chemical facilities worldwide

Operational – Gulf Coast Refinery

| Equipment | Chiller tube sheets in fin-fan coolers |

| Challenge | Severe crevice corrosion at tube-to-tubesheet joints |

| Solution | Curran 500 applied at 35 mils DFT to waterside |

Power Generation Facility

| Equipment | Water box interiors and piping |

| Challenge | Continuous water exposure causing metal loss |

| Solution | Curran 500 coating of all wetted surfaces |

Operational – Chemical Processing Plant

| Equipment | Channel heads in hydrocarbon service |

| Challenge | High humidity and vapor-induced corrosion |

| Solution | Curran 500 application to channel covers |

Operational – Offshore Platform

| Equipment | Firewater and seawater piping systems |

| Challenge | Saltwater-induced corrosion |

| Solution | Internal lining with Curran 500 |

Discuss your heat exchanger/chiller corrosion challenges and operating conditions with a Curran team member.

Curran 500 is specified based on operating temperatures, substrate/metallurgy, service media, and equipment type.

Coordinate with Curran to either purchase the material for use by your own applicators, or request a turnkey proposal for in-situ application performed by our experienced personnel.

Enjoy reduced maintenance and improved reliability over the next decade.

01

Curran 500 requires SSPC-SP 6 commercial blast minimum, with 3 mil surface profile for optimal adhesion. Higher levels of surface preparation will extend coating life.

02

Equipment must be taken offline, cleaned, and dried before application. The coating can return to water immersion service 24 hours after application when tack-free

03

Applications have routinely demonstrated 10+ years of service life in cooling water systems, with some installations exceeding that timeframe.

04

With ~3,800 psi adhesion strength and 7-9 perms water vapor transmission, Curran 500™ provides superior barrier protection compared to traditional epoxy coatings.

05

Yes, damaged areas can be repaired by abrading the affected area and applying additional coats to the required DFT following proper surface preparation.

Please enter your name and email.

We’ll email the data sheets shortly.