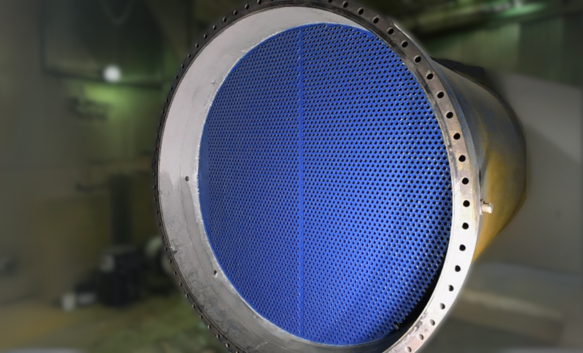

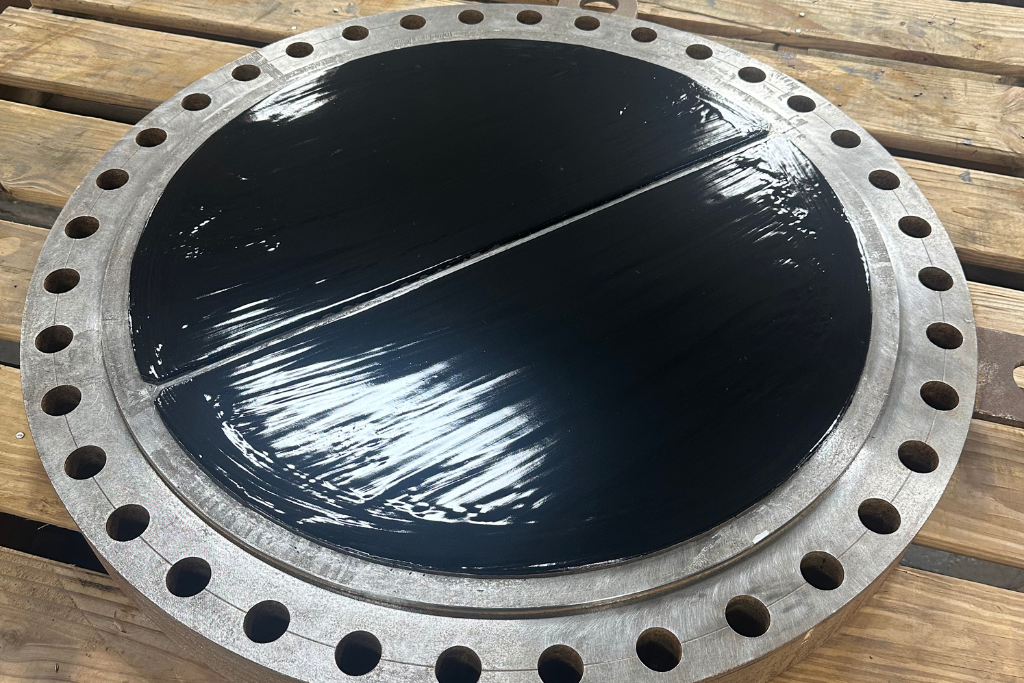

Curran 560 is an advanced carbon fiber-reinforced epoxy coating engineered to strengthen and protect industrial equipment. This high-performance composite coating exhibits excellent flex modulus, superior adhesion, and thermal expansion matching to resist cracking under extreme conditions. Designed for demanding applications including heat exchanger components, pump casings, marine environments, and leaking tanks where thermal distortion exceeds substrate tolerance.

Equipment failures from thermal cycling, corrosion, and coating limitations drive frequent maintenance cycles and structural degradation.

Maintenance due to unprotected surfaces

Carbon fiber epoxy matrix technology provides structural reinforcement with chemical resistance for extended service life.

from 212°F to 32°F with no coating damage

Provides long-term protection in water, chemicals, and hydrocarbons up to 180°F, effectively shielding metal from corrosive process fluids and biofouling.

Maintains integrity through extreme temperature swings with laboratory-proven resistance to 20 rapid thermal cycles without adhesion loss.

Carbon fiber matrix adds mechanical strength to substrates, enabling hole-bridging repairs and reinforcement of thinning walls.

High-gloss finish reduces fouling accumulation and cleaning frequency, with deposits cleaning off more easily during maintenance.

Smooth surface reduces fluid drag in marine environments and piping, improving process performance and energy efficiency.

Ambient cure with 5-7 hour return to water service minimizes maintenance window impact and eliminates high temperature curing requirements.

180°F (82°C) continuous wet exposure with thermal cycling resistance 212°F to 32°F

Spray or trowel application in controlled shop or field conditions with ambient cure

Long-term service design with 8-10+ years proven life extension

Highly tolerant to thermal stress with tailored coefficient of expansion

Ambient cure:

tack-free 5-7 hours, full cure 24-48 hours at 77°

Carbon steel, stainless steel, metallic alloys with SSPC-SP 6 to SP 10 surface prep

Broad resistance pH 2-13, hydrocarbons, water treatment chemicals

32-50 mils DFT recommended for optimal performance

Discuss your corrosion challenges and operating conditions with a Curran team member.

Curran 560 is specified based on operating temperatures, substrate/metallurgy, service media, and equipment type.

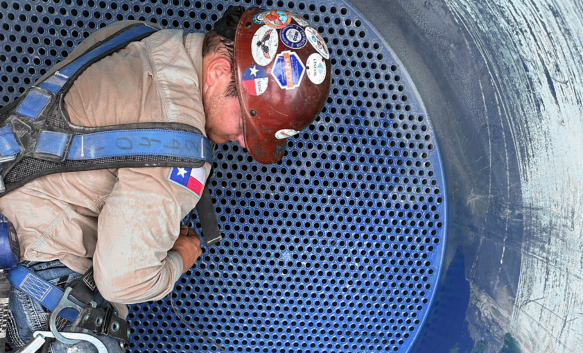

Coordinate with Curran to either purchase the material for use by your own applicators, or request a turnkey proposal for in-situ application performed by our experienced personnel.

Track service life extension and performance improvements.

01

Curran 560 is reinforced with micronized carbon fiber, creating a composite layer with high flexural modulus and thermal expansion matching. This allows it to flex with equipment rather than crack under thermal or mechanical stress, while also providing structural reinforcement capabilities.

02

Curran 560 provides continuous wet service up to 180°F (82°C) and withstands thermal cycling from 212°F to 32°F. It offers broad chemical resistance from pH 2-13 and compatibility with hydrocarbons, making it suitable for most industrial process environments.

03

At 77°F, Curran 560 becomes tack-free in 5-7 hours and can return to water immersion service at that point. Full cure occurs in 24-48 hours. The recoat window is 2-24 hours for additional layers if needed.

04

Curran 560 can be applied to both new and existing equipment. For used equipment, proper surface preparation (SSPC-SP 6 to SP 10) is critical. Many successful retrofits have been completed during maintenance turnarounds to extend equipment life.

05

The recommended dry film thickness is 32-50 mils. This thickness provides optimal structural reinforcement benefits while ensuring proper curing and performance. A 3-quart kit covers approximately 30 sq/ft at 40 mils thickness.

Please enter your name and email.

We’ll email the data sheets shortly.