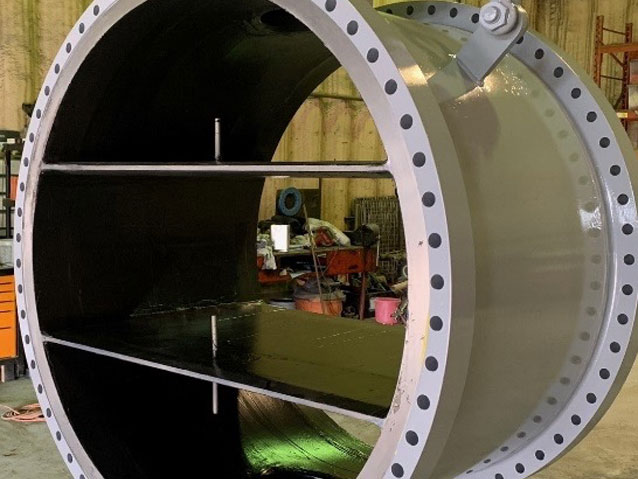

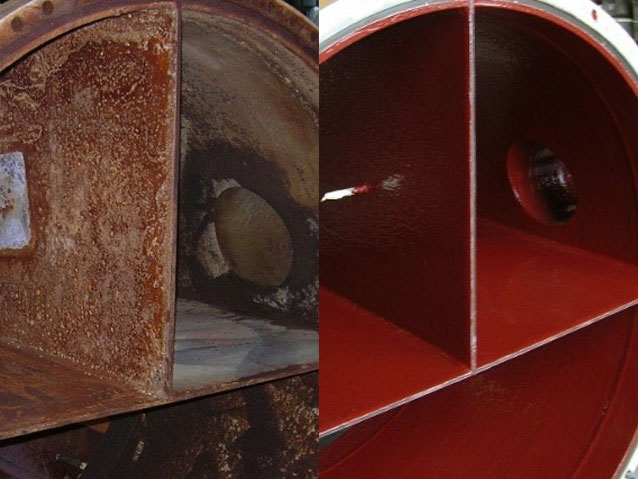

Cooling water exchanger components—channels, bonnets, and covers—often require focused maintenance to remain fit-for-duty. Curran coatings provide extended coverage, preventing corrosion and enhancing reliability.

For chillers, condensers, and HVAC systems, Curran 500 epoxy offers versatile protection. This 100% solids epoxy rebuilds corroded or pitted steel surfaces and provides wide-pH resistance for service temperatures up to 180°F.

All Curran coatings have been tested to ASTM standards for:

- Cathodic disbondment

- Surface adhesion

- Abrasion resistance

Fast Turnaround for Maintenance

Curran’s shop facilities in Houston and Edmonton allow accelerated curing using gas-fired ovens, ensuring coated components are ready for return to service quickly.

For exchanger channels, sealing surfaces, and bonnets, specifying Curran 1500 guarantees superior protection. This ambient-cured, paste-grade novolac epoxy withstands hot excursions up to 385°F and is ideal for flanging-up components for extended service.

Clients have relied on Curran 1000T for cooling water tube ID coatings for over a decade. By combining Curran 1500 coatings with stainless steel anodes, clients report longer anode life and improved corrosion resistance. Curran 1500 is also available for contractor applicators, simplifying in-plant maintenance and just-in-time coating projects.

Learn More

For datasheets, test reports, and application guidance on Curran 1500 and 500 epoxy coating systems, contact Ed Deely at edeely@curranintl.com or 281.339.9993. Visit www.curranintl.com for more information.

Catch Curran: Learn More About Advanced Exchanger Coatings and Services

Curran International provides multiple opportunities to explore its innovative anti-fouling and corrosion-resistant coatings and complete global service portfolio.

Upcoming Industry Events:

- NACE Corrosion 2021 Conference and Expo – Salt Lake City, UT; April 18–22, 2021

- API 2021 Inspection and Mechanical Integrity Summit – San Antonio, TX; June 7–10, 2021

Connect With Curran Anytime

If you can’t wait until these events, you can reach out directly to Ed Deely to learn more about Curran coatings, condenser restoration, tube liner installation, and other turnkey services.

Contact: edeely@curranintl.com | 281.339.9993