Don’t settle for a short service life. Demand more from your protective coatings.

Too often, fixed plant equipment suffers from premature coating failure — leading to unplanned maintenance, shortened service cycles, and expensive repairs. The belief that a coated component can only last a single 4–6 year operating period before a turnaround is not an unavoidable reality.

In most cases, early coating failure can be traced to preventable issues, such as:

- Operating equipment beyond the coating’s functional design limits.

- Inadequate surface preparation or residual contaminants.

- Out-of-spec application or incorrect film thickness.

- Returning an uncured coating to immersion service.

When coatings fail, corrosion to exchanger tubesheets, channels, and bonnets puts equipment integrity and uptime at risk. In turn, emergency repairs during outages often come at expedited rates and with added scheduling complications.

Engineered for Extreme Conditions

Curran Coatings are designed specifically for the most demanding refinery and petrochemical cooling water services worldwide. These 100% solids epoxy systems provide:

- Immersion temperature resistance up to 365°F.

- High-adhesion performance.

- Resistance to cathodic disbondment.

By matching coating properties to all operational demands — including online steam cycling and chemical cleaning — Curran delivers longer service life and lower lifetime maintenance costs.

The Importance of Surface Preparation

Coating professionals agree: 70% of coating performance depends on surface prep. Curran’s process ensures:

- Clean-blasted steel to SSPC or NACE standards.

- Removal of all surface contaminants.

- Proper anchor profile.

- Film thickness applied exactly to spec — too thin risks early permeation, too thick risks cracking and poor inter-coat adhesion.

Even a perfectly applied coating can fail if returned to service before full cure. That’s why Curran uses controlled curing techniques — including heat lamps, warm air circulation, and, in their shop, a specialized oven that achieves full epoxy cure in just four hours. This enables fast turnaround of coated exchanger components without compromising quality.

Curran Coating Solutions for Every Application

Curran 500™

- Two-part 100% solids epoxy, versatile and easy to apply by spray, brush, or roll.

- Designed for all power plant and chiller cooling water systems.

- Ideal for chilled-water tubesheets and steam condensers.

Curran 1000R™

- High-temperature immersion service for cooling water, hydrocarbons, and process streams.

- Two-part 100% solids novolac epoxy, brush or roll applied.

- Water and steam resistant to 365°F; tolerates excursions above 400°F.

- Suitable for exchanger tubesheets in severe environments.

Curran 1200™

- Two-part 100% solids novolac epoxy formulated for tanks and vessels in hydrocarbon and solvent services.

- Spray-applied in single coats of 20–24 mils.

- Engineered for high-volume coating applications.

Curran 1500™

- Hybrid novolac epoxy, 100% solids, designed for cold wall services.

- Atlas Cell tested in deionized water at 365°F under pressure.

- Machinable when fully cured, making it ideal for repairing corroded steel, flanges, channels, bonnets, and uninsulated vessels.

Made in the USA, Applied Worldwide

Curran Coatings are manufactured in Greater Houston, Texas and specified globally. Every project benefits from Curran’s technical guidance and proven track record in protecting high-value assets.

📩 Contact Curran International

- US Sales: Ed Deely — edeely@curranintl.com

- Canada & Overseas Sales: Alex Barre — abarre@curranintl.com

- ☎ Phone: (281) 339-9993

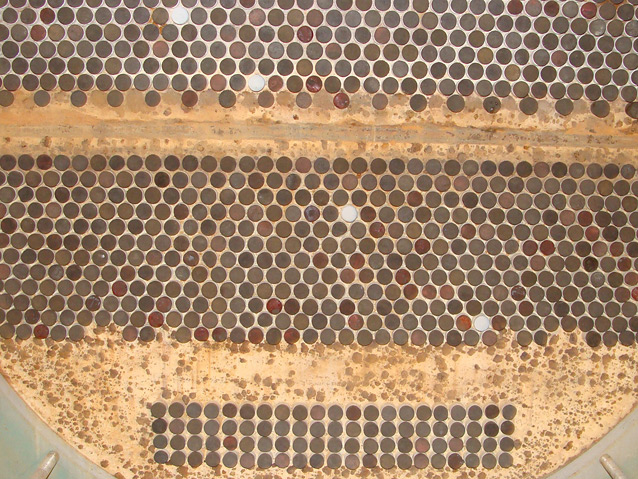

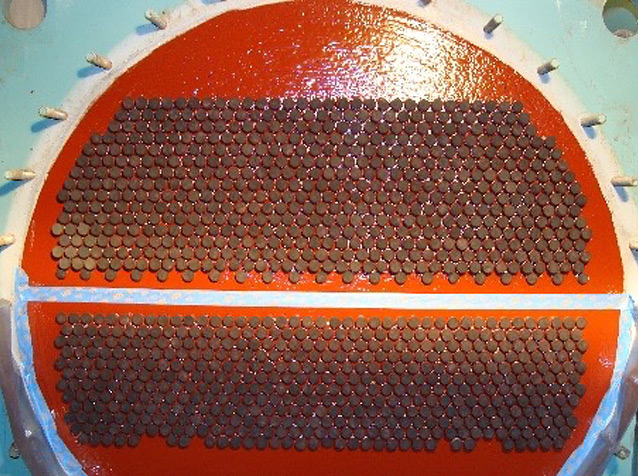

Before & After Example: A chiller tubesheet coated with Curran 500™ is now protected from galvanic corrosion, with tube and tubesheet crevice joints fully sealed — extending service life and improving reliability.