Curran International has partnered with Danish Technological Institute (DTI) to deliver advanced anti-fouling coating solutions for plate and tubular heat exchangers worldwide. This collaboration helps plant operators save time, reduce maintenance costs, and increase heat exchanger efficiency.

The Challenge: Crude Oil Fouling in Heat Exchangers

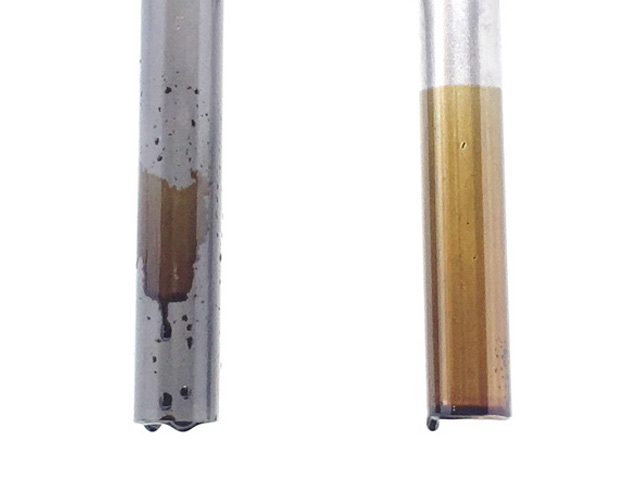

In crude oil extraction and processing, heat exchangers are essential for heating and cooling to stabilize the product. But fouling from crude-oil-derived materials builds up on exchanger surfaces, reducing heat transfer efficiency, forcing costly shutdowns, and creating frequent cleaning cycles that consume resources and extend downtime.

The Solution: Low Surface-Energy Coatings

By applying a low-surface-energy coating to plate heat exchangers, fouling can be dramatically reduced — extending service life by up to six times longer before maintenance is required.

DTI specializes in custom-made anti-fouling coatings like CORE Coat 030, a Sol-Gel-based organic-inorganic hybrid designed for both shell-and-tube and plate exchangers. It’s applied in ultra-thin layers (as low as 5–10 µm), minimizing any impact on heat transfer while providing powerful fouling and scaling resistance, even in high-saltwater environments.

Proven Results from a Global Partnership

Curran International and DTI have already completed numerous projects for offshore platforms and refineries worldwide.

One recent success:

- Client: Major energy corporation in Southeast Asia

- Service: Coating of plate and frame heat exchanger components during scheduled maintenance

- Execution: Coating application at an OEM service depot near the offshore platform

- Outcome: Enhanced fouling resistance, reduced cleaning frequency, and minimized downtime

This combination of DTI’s formulation expertise and Curran’s global application services — available at facilities in Houston, Rotterdam, Singapore, Edmonton, and India or on-site — ensures clients receive turnkey coating solutions anywhere in the world.

Leadership on the Partnership

“Our joint work gives operators solutions that increase production, lower energy use, reduce cleaning events, and minimize health, safety, and environmental risks — especially offshore,” said Edward L. Curran, CEO of Curran International.

“We had worked successfully together for years; the natural next step was a global collaboration,” added Claus Bischoff, Director at DTI.

Global Reach, Local Service

From onshore refineries to offshore platforms, Curran and DTI provide a one-stop-shop for advanced fouling prevention — helping operators cut costs, boost uptime, and extend asset life.

📩 Contact: Alex Barre, General Manager, Curran International

📧 abarre@curranintl.com | ☎ 281.339.9993