Reducing Fouling and Maintenance in Critical Services

Curran International has expanded its portfolio of low-surface-energy coatings designed to combat fouling in crude processing heat exchangers. Targeted applications include crude pre-heaters, vacuum bottoms, FCC slurry exchangers, produced water, and desalting services, where fouling can reduce operational efficiency and increase maintenance costs.

Innovative Materials and Techniques

Curran leverages organic hybrid, inorganic ceramic, and PFA/PTFE coatings to provide reliable anti-fouling performance at temperatures up to 750ºF. Field-installed trials show that coated exchangers can achieve up to three times longer operational runs between shutdowns, minimizing maintenance interruptions.

Key coatings in the portfolio include:

- Curramix – ID, OD, and PFE applications for FCC and vacuum bottoms; effective in heavy gas and oil immersion up to 750ºF.

- StreaMax™ – ID and PFE for hydrocarbons; resistant to paraffins, asphaltenes, H₂S, and CO₂, suitable up to 500ºF.

- DTI Sol Gel – ID and PFE for low-temperature crude (125ºF) and produced water (194ºF).

*ID – tube ID; OD – tube OD; PFE – Plate Frame Exchanger

Ultra-Thin Coatings for Maximum Efficiency

Some Curran coatings are functional at 5–15 microns, dramatically reducing surface tension to <30 dynes/cm² and surface roughness to Ra 0.5 microns. These thin films:

- Improve release and fluid shear at the substrate

- Minimize product attachment and fouling nucleation sites

- Maintain heat transfer efficiency

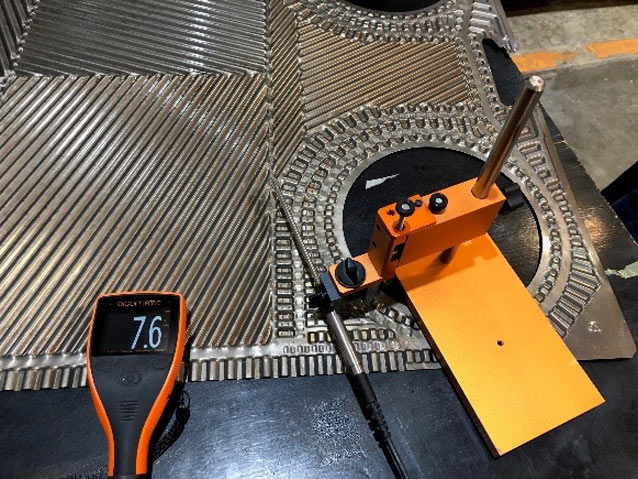

Plate & Frame Exchanger Solutions

In collaboration with the Danish Technological Institute (DTI), Curran applies DTI Sol Gel inorganic-organic hybrid coatings to plate and frame exchangers, including offshore production platforms. Applications are coordinated with OEM maintenance schedules globally, ensuring minimal operational disruption while improving production efficiency and reducing cleaning events.

Global Capabilities

Curran provides field and shop applications at locations in Houston, Edmonton, Rotterdam, and Singapore, ensuring support for a wide range of refinery and petrochemical operations.

Proven Performance

Field trials spanning 15 to 60 months demonstrate consistently favorable results compared with uncoated exchangers, proving Curran’s coatings are an effective, long-term solution to reduce fouling, protect equipment, and sustain throughput.

Contact Curran

To learn more about anti-foul heat exchanger coatings and the full Curran portfolio, contact:

Edward Curran | 281.339.9993 | ecurran@curranintl.com