Curran International, well-known for its industry-leading dry-abrasive grit blasting for tube ID cleaning and surface preparation, also offers another powerful cleaning solution—CO₂ dry ice blasting. This non-abrasive cleaning method is ideal for intricate surfaces, delicate equipment, and applications where abrasive media cleanup is not practical.

Why Choose Dry Ice Blasting?

Dry ice blasting is the preferred choice when:

- Surface delicacy matters – Safe for wood, stone, alloys, and sensitive metals

- Intricate surfaces require thorough cleaning without damage

- Decontamination is a priority in sensitive environments

- Nonconductive cleaning is needed for live electrical equipment

- Zero secondary waste is important – the CO₂ pellets sublimate into gas, leaving no residue

Applications of Curran’s Dry Ice Blasting Services

Our CO₂ non-abrasive blasting is effective for:

- Steam and gas turbine fixed shells

- Electric motor windings and armatures

- Processing plant alloy towers and trays

- Substations, switchgear, and transformers

Dry ice blasting will not create a profile on metal, making it perfect for removing contaminants without altering the base surface.

How Dry Ice Blasting Works

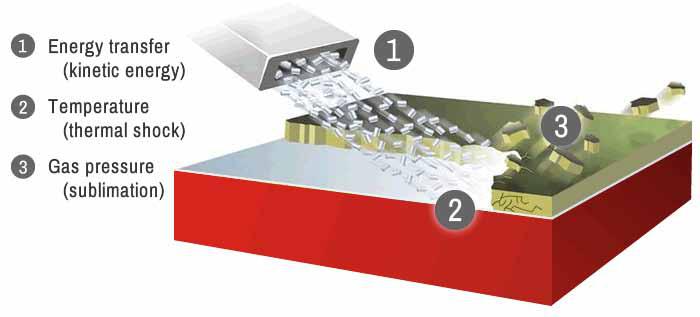

Dry ice cleaning is effective due to two key principles:

- Thermal Shock – Extreme cold causes contaminants to contract and separate from the substrate.

- Kinetic Energy – High-velocity CO₂ pellets impact the surface, delivering cleaning power without abrasion.

When the solid CO₂ pellets hit the surface, the instantaneous sublimation turns the pellets into gas, expanding to 800 times their volume in milliseconds. This rapid expansion creates a micro-explosion effect that lifts away contaminants without damaging the surface.

Considerations for Dry Ice Blasting

While dry ice blasting is highly effective, there are operational factors to consider:

- Small blasting radius (~1 in²) means larger surfaces take longer to clean

- Requires high-pressure air compressors (140–180 psi)

- Cold chain management is critical—CO₂ pellets must remain solid for maximum impact

- On-site CO₂ pellet makers are available but can be costly

Grit Blasting vs. Dry Ice Blasting

Both blasting methods have their place in industrial maintenance:

- Grit blasting is best for aggressive surface preparation and creating surface profiles

- Dry ice blasting is best for non-abrasive cleaning, decontamination, and delicate applications

Curran International brings decades of blasting expertise—whether you need abrasive grit blasting or precision dry ice cleaning.