Curran International provides Eddy Current Tube Testing (ECT)—a reliable, cost-effective method to identify tube wall loss, cracks, pits, and other defects before they cause costly downtime. By detecting damage early, ECT helps extend heat exchanger availability and prolong equipment lifespan.

How Eddy Current Tube Testing Works

Eddy Current Testing uses an alternating current (AC) magnetic field to induce electrical currents—called eddy currents—in non-ferrous materials. These currents flow along the material’s geometry but are disrupted by nonconductive areas like cracks, corrosion pits, or thinning metal.

When calibrated against a known standard, ECT instruments can:

- Detect and locate tube defects

- Measure defect size and severity

- Quantify tube wall loss

By analyzing signal amplitude, phase angle, and shape, Curran’s NDE Technicians can accurately diagnose issues without removing tubes from service.

Case Study: Detecting Stress Corrosion Cracking in Feedwater Heaters

A power facility contacted Curran International after experiencing multiple tube leaks in their feedwater heaters.

Step 1 – Initial Inspection:

A walk-down inspection revealed no obvious external issues.

Step 2 – 100% Eddy Current Inspection:

The ECT scan revealed multiple cracks located at or near tube support plates—classic signs of Stress Corrosion Cracking (SCC).

Step 3 – Root Cause Analysis:

Although plant management initially ruled out SCC due to the absence of chlorides in the system, further investigation revealed a hidden culprit:

- Years earlier, a biocide containing trace chlorine had been used in cooling towers.

- When leaks occurred, the maintenance team often used sawdust in the intake to plug leaks, delaying repairs.

- The chlorides from the biocide entered the condensate, causing SCC and leading to premature tube failures.

Step 4 – Metallurgical Examination:

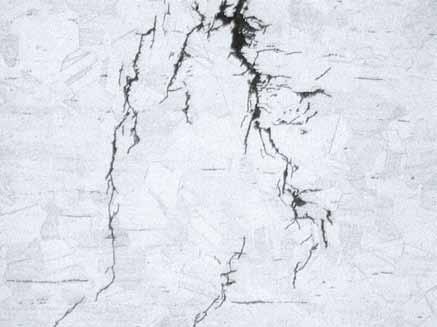

A pulled tube sample confirmed highly branched transgranular cracks originating from chloride-induced SCC.

Results & Corrective Actions

- Cracking was found in four of five feedwater heaters tested.

- Preventative measures were implemented to extend equipment life until retubing with chloride-resistant alloys could be performed.

- Biocide chemistry was changed to prevent recurrence.

- A comprehensive ECT program was recommended for the condenser and other critical heat exchangers.

Why Choose Curran for Eddy Current Testing?

- Experienced NDE Technicians with industry-proven expertise

- Advanced calibration and defect quantification methods

- Ability to detect hidden damage before catastrophic failure

- Tailored corrective and preventative maintenance plans

Don’t wait for tube failures to force an unplanned outage. Curran can help identify the root cause of damage and put corrective actions in place to minimize future risk.