When it comes to protecting your cooling water equipment, Curran 1500 coating delivers superior, long-lasting corrosion resistance—even on heavily pitted surfaces.

Tackling Corrosion in Cooling Water Channels

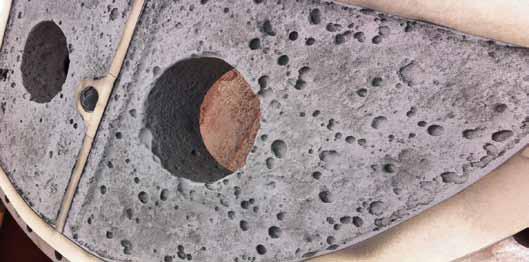

In many plants, corrosion pits deeper than 0.0625” develop on channel surfaces exposed to cooling water. These pits create a challenge for equipment longevity and maintenance costs.

Curran’s solution? A multi-coat application of Curran 1500, applied at 2-3 coats with a total dry film thickness (DFT) averaging 0.100”. This creates a homogeneous corrosion-resistant film that greatly extends service life and protects vulnerable steel surfaces.

Why Do Coatings Fail Prematurely?

Plant operators often face frustration when immersion coatings fail well before their expected lifespan. Common root causes include:

- Coatings not designed for actual operating conditions

- Poor surface preparation before coating application

Curran addresses these issues with high-performance 100% solids coatings that provide:

- Superior adhesive strength

- Excellent resistance to cathodic disbondment

- Proven durability in hot immersion environments

Surface Preparation: The Foundation of Long-Term Protection

Proper surface preparation is critical for immersion coatings to perform. Starting with a clean, contaminant-free surface is essential.

Curran follows industry standards from NACE and the Society of Protective Coatings (SSPC), ensuring:

- Consistent application practices

- Thorough surface prep and evaluation

- Coating coverage that meets or exceeds specifications

Tested and Proven Performance

Curran 1500 coatings come backed by rigorous ASTM testing, including:

- Tensile adhesion testing

- Cathodic disbondment resistance

- Abrasion resistance

- Atlas Cell testing up to 185°C (365°F) for 30 days

In immersion cycle testing, Curran 1500 has performed without failure even at 400°F, demonstrating robust thermal and chemical resistance. Adhesion pull tests have shown strengths up to 3800 PSI.

Designed for the “Cold Wall” Challenge

One major cause of coating failure in hot immersion service is the “cold wall” effect—when a hot internal surface is adjacent to a significantly cooler external surface, causing thermal stress that can blister coatings.

Few epoxies can withstand this, but Curran 1500 is formulated to resist thermal cycling and cold wall stresses, ensuring protection even during upset conditions.

Versatile Application and Use Cases

Curran 1500 is ideal for:

- Cooling water exchanger components

- Equipment with pitted or damaged surfaces

- In-service repairs and new fabrications

Its paste-grade formulation allows excellent wetting in crevices, such as tube-to-tubesheet joints, and easy application with a plastic coating blade. Once cured, it can even be machined at flanged mating surfaces for precise fitment.

Contact Curran International

To learn more about Curran 1500 and our full range of protective coating solutions for immersion and hot water services, contact Curran International at (281) 339-9993 or email edeely@curranintl.com.