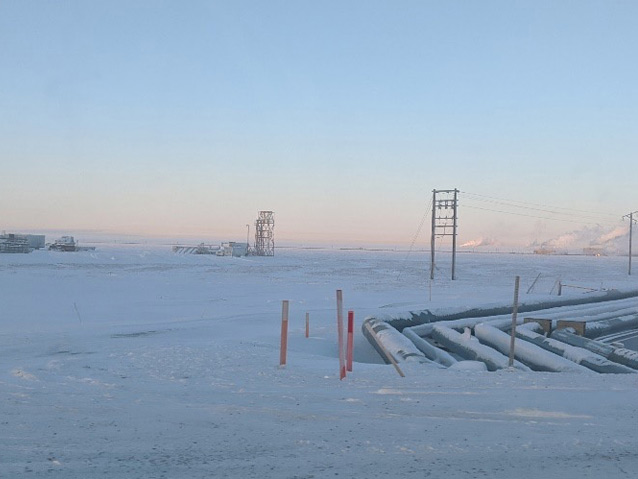

In January, a Curran International crew traveled 300 miles north of the Arctic Circle to Deadhorse, Alaska, elevation 15 feet, population 25, to apply an anti-foul exchanger coating during routine maintenance for a Prudhoe Bay pipeline operator.

Extreme Conditions, Exceptional Work

The Arctic winter offered temperatures as low as -40°F and more than 23 hours of nighttime darkness, providing the team a rare chance to witness the Aurora Borealis while on assignment. Thanks to CCI Industrial Services, the Curran crew worked in a weather-hardened maintenance shop, performing surface preparation and full-length tube ID coating in a controlled environment.

The exchanger operates in 190°F produced-water service, where chlorides, particulates, and organic compounds from oil and gas wells contribute to fouling and corrosion. Regular maintenance schedules had not fully mitigated these challenges, impacting heat exchanger efficiency and reliability.

Minimal Thickness, Maximum Results

The pipeline operator specified a low-surface energy, omniphobic Curran coating applied to the full-length tube IDs. At less than 2 mils thick, the coating reduced surface tension, minimized foul attachment, and maintained optimal heat transfer performance.

This application highlights Curran’s ability to deliver anti-fouling solutions in extreme environments, combining technical precision with field adaptability.

Put Curran’s Coatings to Work

Curran’s portfolio of anti-fouling and corrosion-resistant coatings can improve reliability and performance across a wide range of services and operating conditions.

For more information or to review your operating conditions, contact Ed Curran at ecurran@curranintl.com or 281.339.9993.