Curran’s Fin Fan Tube Cleaning is a patented dry abrasive cleaning method that removes tenacious scale and deposits from air cooler tube IDs without water introduction.

Using high-velocity grit delivered through proprietary nozzles, this turnkey service prepares tubes for high-integrity NDE inspections while restoring heat transfer efficiency through complete scale removal.

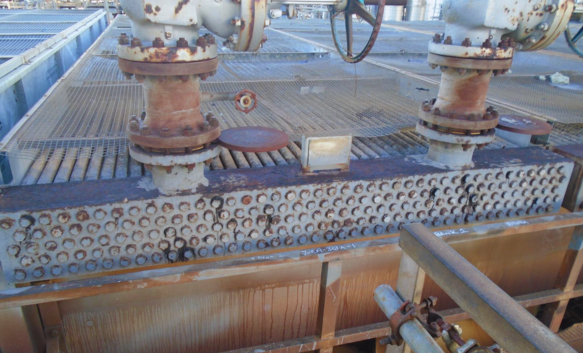

Air cooler tubes accumulate tenacious calcium carbonate scale and hydrocarbon deposits that resist traditional cleaning methods.

This fouling reduces heat transfer efficiency and prevents accurate NDE data acquisition.

Hydro Pressure Still Ineffective

Curran’s patented dry grit blasting delivers turbulent, high-velocity cleaning that scours full-length tube IDs to IRIS-ready cleanliness. The vacuum-tight pitch and catch containment system bridges headers, keeping catwalks clean.

Velocity Air & Grit Delivery

Fin fan tube cleaning delivers measurable improvements in heat transfer efficiency and inspection reliability.

By achieving IRIS-level cleanliness without water introduction, facilities reduce turnaround time while enhancing data quality for informed maintenance decisions.

Remove fouling deposits to recover thermal performance and reduce energy consumption

Achieve greater probe fill factor and sensitivity to small defects with clean tube surfaces

Eliminate cleaning rework and minimize equipment downtime with predictable execution

Mitigate under-deposit corrosion and reduce mechanical tube plugging requirements

Maintain consistent heat removal capacity and avoid unplanned outages

Complete cleaning in First-Third of outage timeline with no water drying delays

Position blast pots, dust collectors, and containment systems with electrical tie-ins

Partner with the industry leader in dry abrasive tube cleaning for reliable heat exchanger performance

Share your equipment details and inspection requirements for customized solution

Coordinate equipment staging and utility connections for seamless execution

Experience predictable cleaning with real-time quality verification

Receive documented results and enhanced NDE data for maintenance planning

01

Curran's patented nozzles bridge the header box on both sides, preventing grit entry while one technician blasts and another catches debris. This eliminates the need for elevated containment and allows work from existing catwalks.

02

The dry grit blast process is compatible with all common tube metallurgies including carbon steel, stainless steel, admiralty brass, and copper-nickel alloys. Dwell times are calibrated to prevent wall loss.

03

Typical four-bank air cooler cleaning completes in 6 days including mobilization, execution, and demobilization. Per-tube cleaning times range from 5-30 seconds depending on fouling severity.

04

Grit blast cleaning enables IRIS, RFT, and ECT inspections with enhanced sensitivity. The clean surface provides a better probe fill factor and reduces background noise for accurate defect sizing.

05

All spent blast media is collected through vacuum-tight containment into client-provided waste bins or drums. Approximately 2 cubic yards of waste generates per 4,400 pounds of blast media used.

Please enter your name and email. We’ll be in touch soon.