When refinery inspection and reliability teams gathered at a Saudi Aramco maintenance facility, they expected a cleaning demonstration. What they saw was proof that Curran’s grit-blasting technology can outperform conventional methods—and do it fast.

The Challenge: Hydro-Lancing Left Too Much Behind

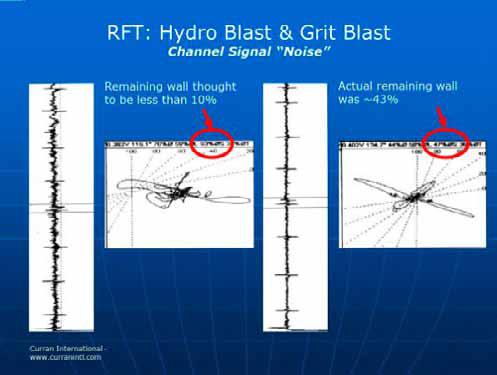

Straight and U-tube carbon steel exchangers had already been hydro-lanced, but the cleaning was incomplete.

The problem?

- Heavy surface scale still restricted the inspection probe from traveling more than a few inches into the tubes.

- Without a clear path, inspectors couldn’t gather the data they needed.

The Curran Solution: 40 Seconds to a Clean Tube

Curran’s grit-blast cleaning method was put to the test—side-by-side against the hydro-lanced tubes.

The results:

- In just 40 seconds, grit-blasting removed the remaining scale

- A borescope confirmed a clear, full-length tube

- The inspection probe passed end-to-end without obstruction, enabling complete inspection data collection

Why It Matters for Global Refineries

This wasn’t just a demo—it was proof of how faster, more thorough cleaning can directly improve inspection accuracy and reliability planning.

With international partners and representatives in the Middle East, Singapore, Rotterdam, and Edmonton, Curran International delivers this level of cleaning performance worldwide.

Contact:

📧 Alex Barre — abarre@curranintl.com

📞 (281) 339-9993