Preventing Erosion in Quench Water Exchangers

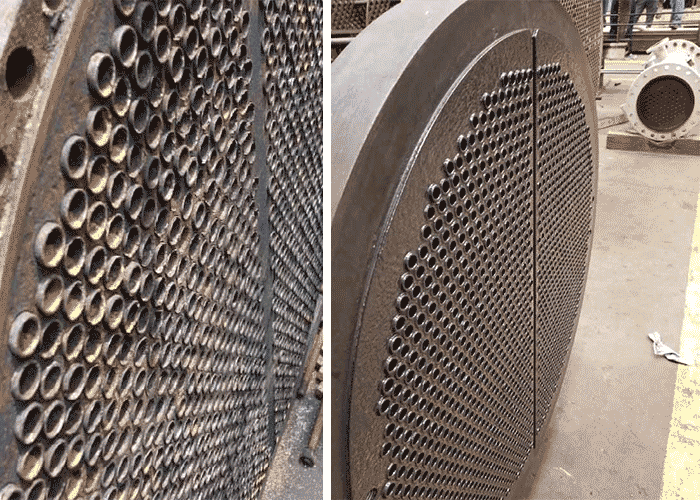

During routine maintenance of quench water exchangers, plant inspectors observed tube-end erosion across most of the bundle. Many tubes were eroded flush with the tubesheet, threatening sealing integrity. The plant’s tube-side service includes hot, turbid quench water and hydrocarbons, with fluid velocities below 3 ft/second.

To safeguard the exchanger’s functionality, tubesheet remediation and protective coating were selected as the most effective solution.

Selecting the Right Coating

Curran 1500, a high-functionality novolac hybrid epoxy coating, was chosen for its mechanical strength and suitability for cold-wall service.

- Cold-wall service occurs when one side of steel is exposed to hot water while the opposite side is cooler. Standard coatings risk blistering under these conditions.

- Curran 1500 is 100% solids, 0 VOC, and designed to withstand the molecular kinetic energy of hot immersion service.

Step-by-Step Project Execution

- Surface Preparation: Tubesheets were grit-blasted to NACE 1 white metal, and soluble contaminants (chlorides) were remediated.

- Primer Application: Using a short brush, a primer coat was applied at tube and tubesheet joints. The primer encapsulated crevices and extended about ¾” down the tube to prevent erosion.

- Curran 1500 Coating: Two coats were applied, achieving 32–40 mils total thickness across the tubesheets. The amine-catalyzed coating cures at ambient temperatures.

The result: restored tube-end protection, preserved sealing integrity, and enhanced corrosion resistance.

Why This Matters

Curran 1500 provides a durable, high-performance solution for challenging tubesheet environments. It is suitable for a wide range of industrial applications, including fixed equipment and pressure vessels exposed to hot immersion and cold-wall conditions.

Learn More

Contact Ed Deely for details about Curran coatings and tubesheet restoration solutions:

- Email: edeely@curranintl.com

- Phone: 281.339.9993