Introduction

In power plants, refineries, and industrial facilities, condenser tube cleanliness directly impacts heat transfer efficiency, energy consumption, and equipment life cycle. Fouling, scaling, and under-deposit corrosion are persistent challenges, often leading to reduced performance and costly downtime.

This case study compares traditional mechanical cleaning methods—metal scrapers and nylon tube brushes—with tubular grit blasting (media blasting) to demonstrate which method achieves the highest standard of tube restoration and ensures long-term reliability.

What is Tubular Grit Blasting?

Tubular grit blasting, also referred to as media blasting, is a surface preparation technique that uses compressed air to propel fine, non-destructive abrasive media through condenser tubes. Unlike mechanical brushes or scrapers, grit blasting removes hard, tenacious deposits without damaging the tube wall.

This method restores tubes closer to their original surface condition, improves heat exchanger efficiency, and provides a superior surface for nondestructive examination (NDE) by minimizing background noise and improving signal clarity.

Section 1 – Traditional Mechanical Cleaning

Mechanical methods such as metal scrapers and nylon tube brushes have been widely used for decades. While they can dislodge loose deposits, these tools have limited effectiveness against hard, baked-on fouling and corrosion scale.

- Metal scrapers risk damaging tube surfaces, introducing scratches that can become corrosion initiation points.

- Nylon brushes provide a gentler clean but are generally ineffective against mineral deposits or hard scale.

- Neither method exposes the bare tube wall, leaving residual deposits that restrict heat transfer and increase back pressure.

Section 2 – Tubular Grit Blasting Process

In this study, condenser tubes underwent media blasting at varying dwell times (30 seconds, 1 minute, 2 minutes). The process effectively stripped away oxide layers, scaling, and fouling, restoring a clean metallic surface.

Key advantages include:

- Complete removal of stubborn deposits.

- Exposure of the true tube wall condition.

- Enhanced thermal conductivity due to cleaner surfaces.

- Longer-lasting results compared to mechanical cleaning methods.

Section 3 – Impact on Reliability and NDE

Cleanliness is not just about efficiency—it’s also about reliability. Tubes cleaned with media blasting showed significant improvements in nondestructive evaluation (NDE) accuracy.

- Reduced background noise enabled higher sensitivity to small defects.

- A better fill factor and cleaner signals resulted in faster data acquisition.

- Early detection of pitting, wall loss, and other defects became possible, allowing predictive maintenance rather than reactive repairs.

Results

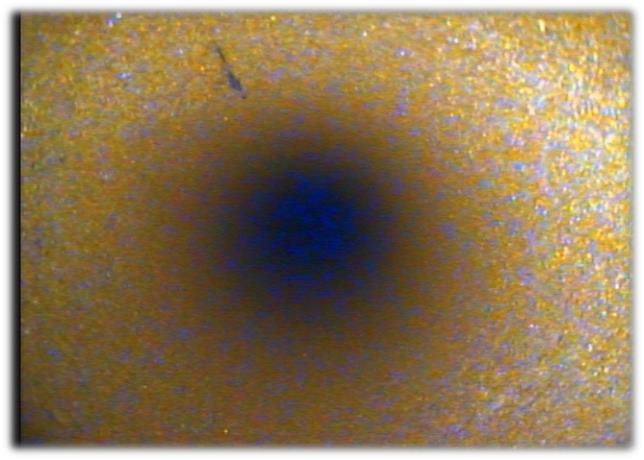

The side-by-side comparison revealed clear differences:

- As Found Condition: Heavy fouling and scaling reduced performance and complicated inspection.

- After Metal Scrapers / Nylon Brushes: Partial cleaning with residual deposits still clinging to the tube wall.

- After Grit Blasting: Fully restored tubes with visible metallic surfaces, ready for inspection and optimized for heat transfer.

Lessons Learned:

- Media blasting removes hard deposits more effectively than mechanical cleaners.

- Eliminating under-deposit corrosion risks extends tube longevity.

- Cleaner tubes reduce tube velocity and back pressure, improving unit performance.

- Efficiency gains often offset the additional cost of grit blasting within a single maintenance cycle.

Conclusion

When it comes to condenser tube cleaning, not all methods are equal. While traditional mechanical tools provide temporary results, tubular grit blasting offers a superior long-term solution. By fully restoring surfaces, enabling more accurate inspections, and improving thermal performance, grit blasting helps facilities maximize uptime, extend equipment life, and achieve measurable cost savings.

Contact Us

Are your condenser or heat exchanger tubes limiting performance?

Contact Curran today to learn how tubular grit blasting services can restore efficiency, enhance reliability, and provide a measurable ROI on your next maintenance cycle.