INTRODUCTION

Curran has spent the last 12 years in a JDA with A Super Major Oil & Gas Refiner creating advanced coatings & surface treatments aimed at significantly reducing fouling and corrosion in crude preheat exchangers.

Our collaboration led to a breakthrough surface treatment that delivers superior results.

The results speak for themselves, as Minimox has proven to enhance efficiency, reduce maintenance, and extend equipment life in critical operations.

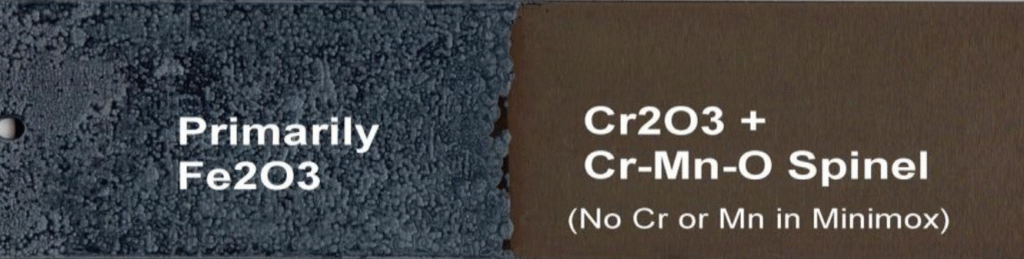

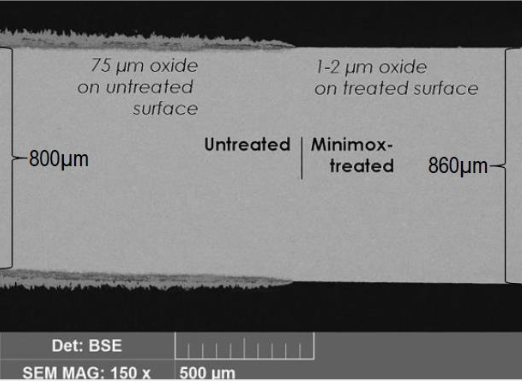

Before: 75 μm Oxide + Pitting

After: 1-2 μm Oxide + Minor Pitting

What is REO Surface Treatment?

- It’s a Self-protective alloy treatment.

- Not a traditional, continuous coating, more like surface treatment.

- Has no measurable coating mass or coating thickness

- Protects from high temperature oxidation and imparts low surface energy

SECTION 1: Minimox Technical Benefits

- Low surface energy leading to low fouling and coking rates.

- Eliminates high temperature metal dusting.

- Creates thin and smooth layer Flexible & robust

- High temperature stability. No REO imposed limits.

- Inside and outside surfaces can be protected.

- No VOC, pH = 7

- Can be applied by dipping or spraying. Curing at 400 °C for 1 hour

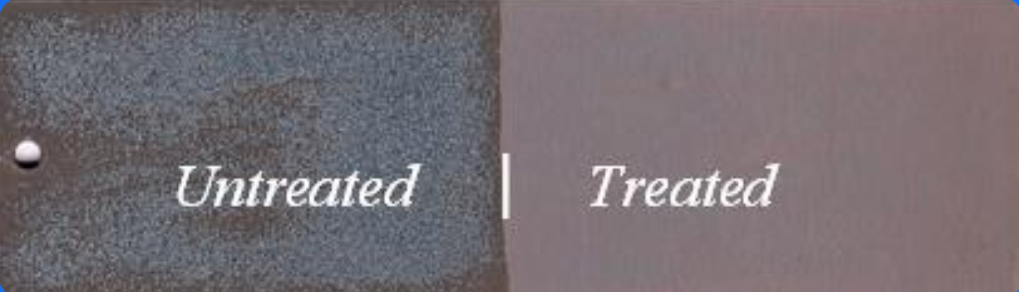

See the difference: Uncoated VS Coated Coupon

Untreated coupon: thick flaking brown oxides

REO treated coupon: thin gold colored oxide with adherent spinel – improved surface integrity

SECTION 2: Minimox Lab Testing Results

Bench Tests: Minimox Efficacy

Oxidation Reduction: Cross section of 410 SS coupon shows about 60 μm metallic loss due to untreated side

Carburization Reduction: 316L coupon partially treated with Minimox, held in a carburizing furnace for 168 days at 760°C

Super Major Testing in Correlation w/ Fouling

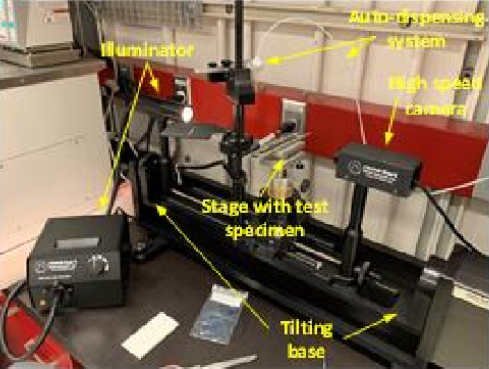

Ramé-Hart Model 590 automated tensiometer used for coupon SFE measurements

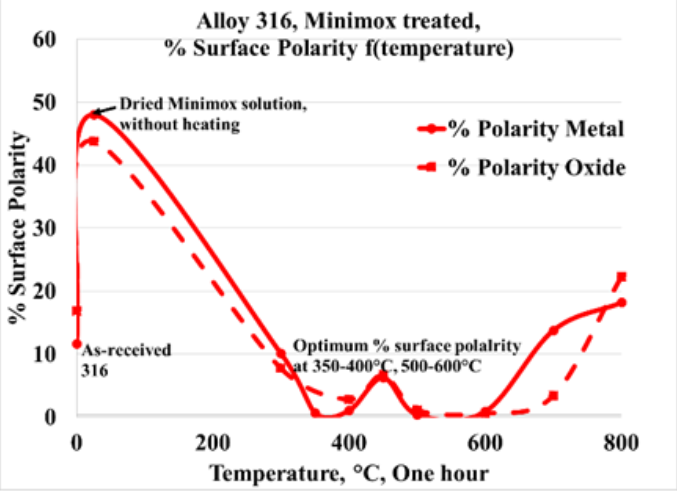

Quantifying polar component of total SFE allows surface polarity to be calculated

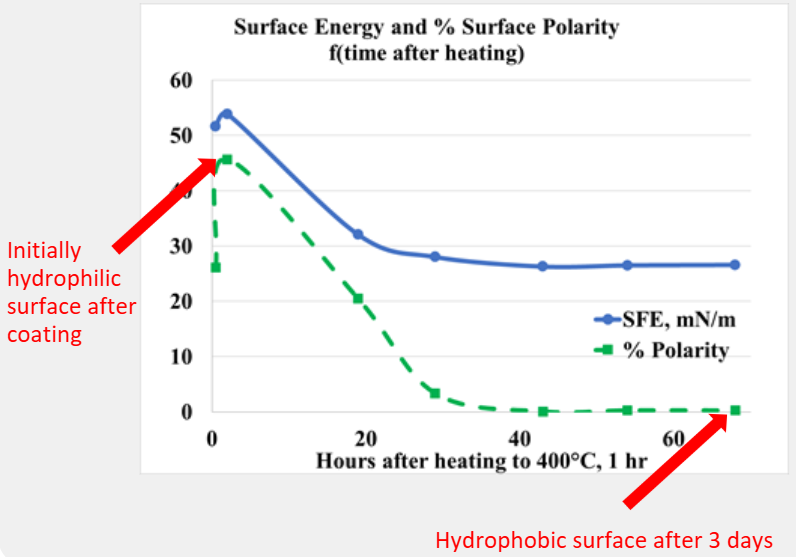

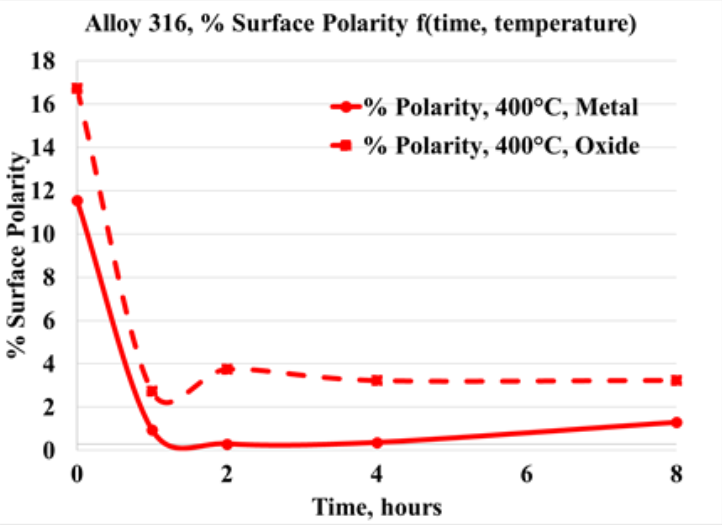

Surface energy and % surface polarity as a function of time after heating (400°C, 1 hr)

Minimizing energy of a surface reduces the strength of any potential adhesive interaction between the surface and a fouling material

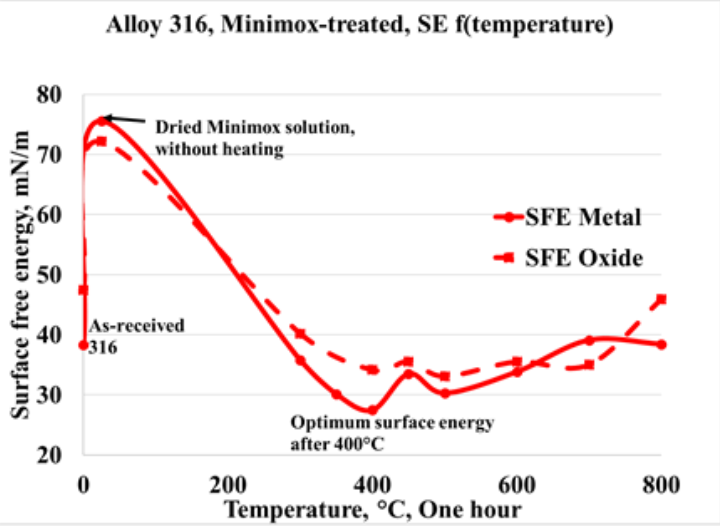

Surface Energy of Minimox-Treated Alloys

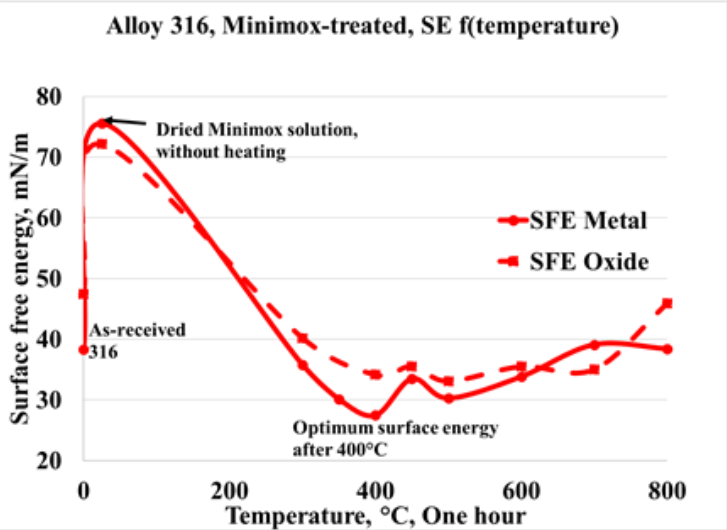

Surface energy of 316L stainless after coating with Minimox 721 and heating for one hour at various temperatures

Temperature for optimum surface energy was 400 °C for one hour.

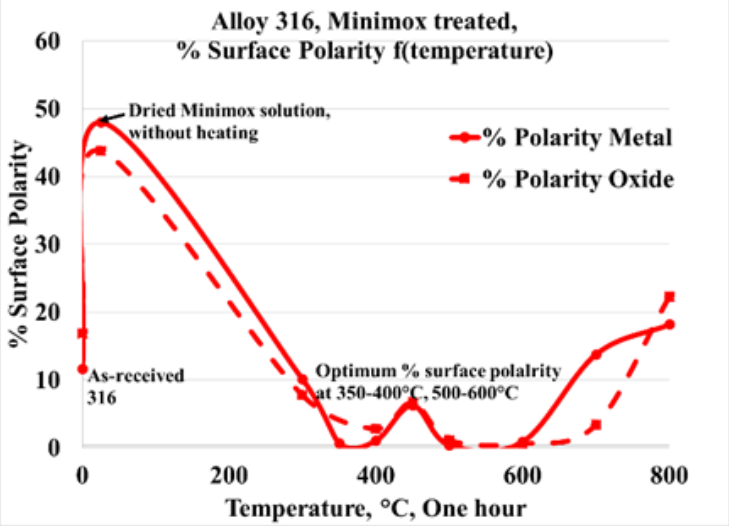

Percent surface polarity of 316L after coating with Minimox 721 and heating for one hour at various temperatures

Temperature for optimum percent surface polarity was 400 °C for one hour

Effects of time on the surface energy and surface polarity (Kinetic experiments)

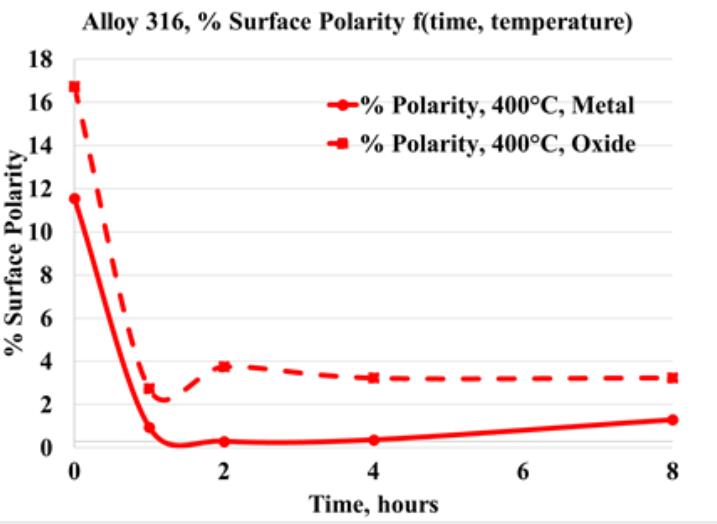

% Surface polarity of 316L after coating with Minimox 721 and heating to 400°C in air for various times

Heating the sample for longer times at 400°C in air still leads to very low percent surface polarity.

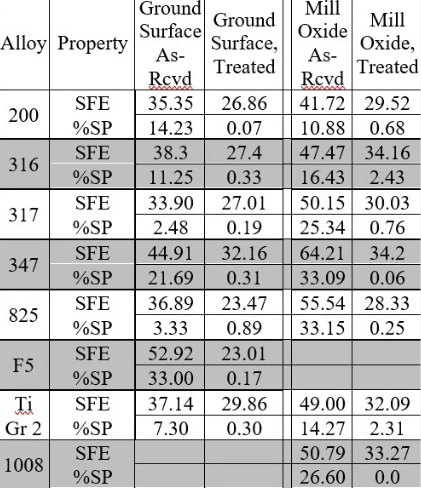

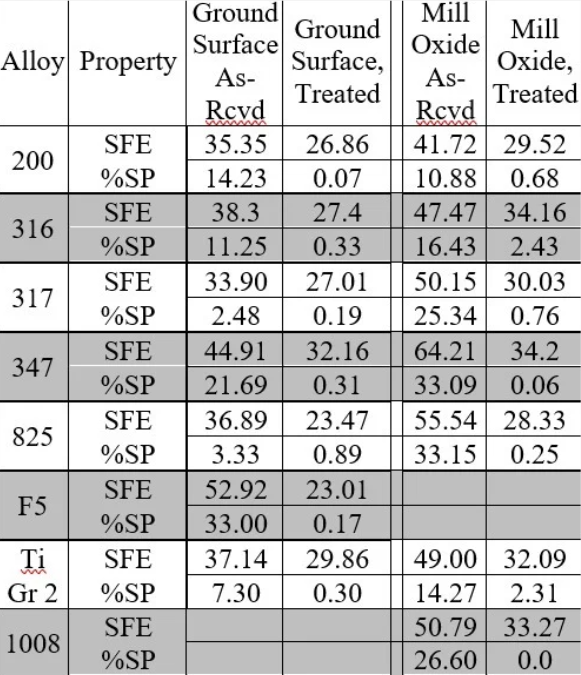

Surface free energy (SFE, mN/m), and % surface polarity (%SP) of selected alloys for 200 grit Ground Surface and Mill Oxide Surface

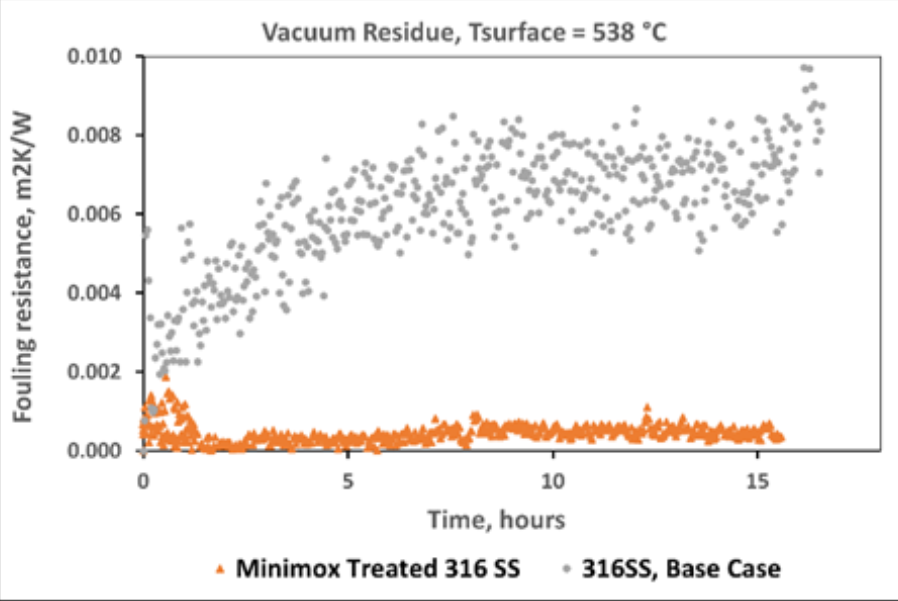

Fouling Resistance of Minimox-Treated Alloys

- Fouling experiments performed in test rig utilizing electrically heated vertical tube equipped with multiple stationary thermocouples measuring surface temperatures

- Fouling resistance tests for Minimox-treated tubes performed with vacuum residue in once-through mode and test tube temperature of 538 °C; corresponds to skin temperatures in Coker furnace tubes

- The once-through operation limited test run to 16 hours

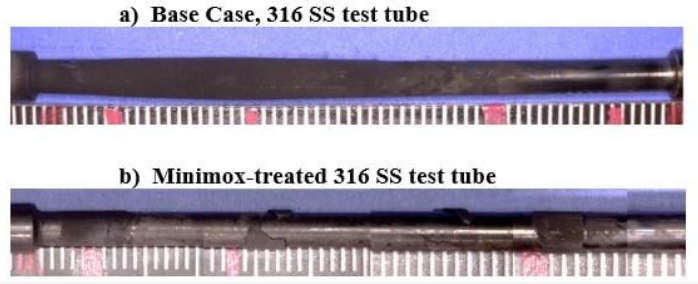

Fouling resistance for Minimox treated 316 SS test tube in a once-through experiment

Reduction in coke formation in vacuum residue fluids

Minimox treatment reduced coke formation by about 80% and adhesion of coke to tube was greatly reduced too

Reduction in fouling in other process fluids

- Similar fouling resistance tests caried out for lighter, less challenging process fluids handled in the refineries

- Experiments performed in recirculation mode for 40 -50 hours with 316 SS tubes

- Results led to same conclusion that Minimox treatment of stainless-steel tubes reduced fouling rates and accumulation of deposits

Surface Energy of Minimox-Treated Alloys

Surface energy of 316L stainless after coating with Minimox 721 and heating for one hour at various temperatures

Temperature for optimum surface energy was 400 °C for one hour.

Percent surface polarity of 316L after coating with Minimox 721 and heating for one hour at various temperatures

Temperature for optimum percent surface polarity was 400 °C for one hour

Effects of time on the surface energy and surface polarity (Kinetic experiments)

% Surface polarity of 316L after coating with Minimox 721 and heating to 400°C in air for various times

Heating the sample for longer times at 400°C in air still leads to very low percent surface polarity

Surface free energy (SFE, mN/m), and % surface polarity (%SP) of selected alloys for 200 grit Ground Surface and Mill Oxide Surface

SECTION 3: Super Major Case Study

Introduction:

In an industry where operational efficiency and equipment longevity are critical, minimizing fouling and coking in heat exchangers can lead to significant cost savings and improved performance.

A Super Major Oil & Gas Refiner recently conducted a year-long study using Minimox, a cutting-edge surface treatment technology, to coat both the internal and external surfaces of crude preheat exchangers.

The results? Substantial improvements in efficiency, reduced maintenance costs, and extended service life.

Background:

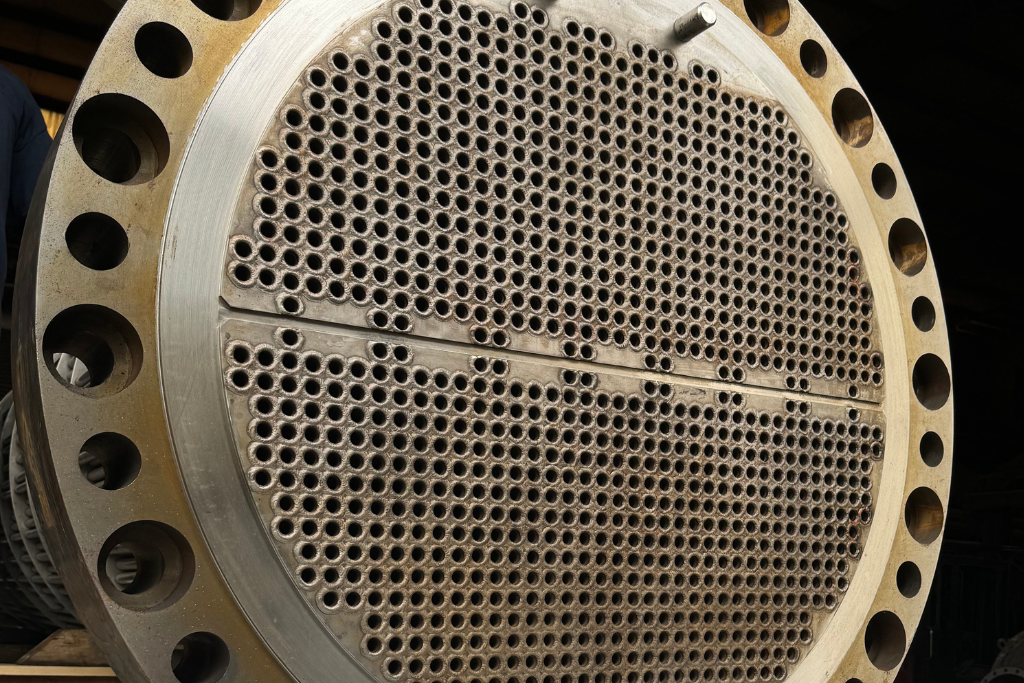

A Super Major Oil & Gas Refiner implemented Minimox surface treatments on several key heat exchangers within their crude preheat train, focusing on two units:

- ESE Isomax E-540: Hydroprocessing feed/effluent exchanger.

- RIC Crude E-1165: Crude-to-resid flash exchanger.

These exchangers play a critical role in preheating crude oil before entering the furnace, an essential step in refinery operations. Historically, fouling and coking have been persistent issues, leading to inefficiencies, higher energy consumption, and costly downtime for maintenance.

The Challenge:

Crude preheat exchangers are prone to fouling and coking due to the high temperatures and complex feedstocks used in refineries. This results in:

- Increased fuel consumption due to higher furnace inlet temperatures.

- More frequent shutdowns for cleaning and maintenance.

- Decreased thermal efficiency, negatively impacting overall refinery performance.

The Super Major Oil & Gas Refiner was seeking a solution that could mitigate these issues, improve the performance of their heat exchangers, and reduce operational costs.

The Results: Significant Efficiency Gains and Costs Savings

RIC Crude E-1165 (Crude-to-Resid Flash Exchanger):

- Service duration: In operation since August 2023.

- Rf improvement: 50% increase in thermal efficiency.

- Furnace Inlet Temperature Reduction (dT): 1.5°F drop.

- Energy savings: Reduced energy consumption by 3.0 MMBTU/hr (per SmartPM runs).

Key takeaway: The 50% improvement in fouling resistance on the crude preheat exchanger significantly reduced energy costs and delayed the onset of performance degradation.

ESE Isomax E-540 (Hydroprocessing Feed/Effluent Exchanger):

- Service duration: In operation since October 2023.

- Rf improvement: 20% increase in thermal efficiency.

- Furnace Inlet Temperature Reduction (dT): 11°F drop.

- Energy savings: Reduced energy consumption by 2.0 MMBTU/hr (per HTRI runs).

Key takeaway: The 20% improvement in fouling resistance led to increased operational efficiency, reducing the need for frequent maintenance and lowering operational costs.

Bonus Data:

Crude Vacuum Column Wash Bed (Minimox Treated Grid and Structured Packing):

- Service duration: In operation since July 2020.

- Observed results: Minimox was still present nearly four years later, with a delayed onset of bed fouling by 16 months.

Key benefit: The Super Major Oil & Gas Refiner avoided costly maintenance shutdowns and saw continuous performance, despite less-than-ideal initial application conditions.

SECTION 4: Conclusion

The ROI of Minimox Coating:

The Super Major Oil & Gas Refiner’s experience demonstrates that even a one-week delay in fouling or coking can offset the cost of applying Minimox. In fact, the cost savings generated by the additional uptime often exceeds the initial investment in the coating.

Minimox provides a clear business case for refineries looking to reduce downtime, increase throughput, and improve energy efficiency in their crude preheat exchangers. The application of Minimox offers:

- Longer intervals between cleanings, reducing maintenance costs.

- Reduced energy consumption, leading to significant fuel savings.

- Improved throughput, allowing refineries to process more challenging feedstocks.

- Allow Faster and Easier Hydroblast Cleaning: Data showed Hydroblast Cleaning was 7 to 10X Faster on Minimox Coated Exchangers.

Are you ready to achieve similar results?

Contact us to request a free consultation to learn more about the application process and the data behind The Super Major Oil & Gas Refiner’s success.

+1 281 339-9993 | sales@curranintl.com | www.curranintl.com