Protecting personnel and the environment from hazardous emissions like benzene is critical for refinery operations. Curran International recently provided a proven solution to prevent benzene leaks from refinery heat exchangers — safeguarding workers and complying with EPA regulations.

The Benzene Leak Challenge

Benzene is classified by the EPA as a Group A known human carcinogen, making any atmospheric leaks a serious health and environmental concern. A major refinery contacted Curran after identifying leaks in their benzene condensers, risking exposure to plant personnel and potential regulatory violations.

Diagnosing the Problem: Tube-to-Tubesheet Weld Erosion

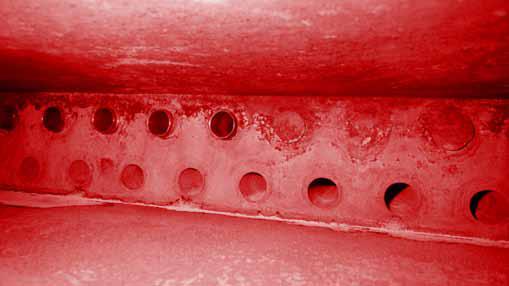

Upon arrival, Curran’s technicians inspected the affected condensers. They found that benzene flow through the condenser headers was eroding the tube-to-tubesheet welds, compromising the integrity of the tube joints. This damage allowed benzene to vent through the annulus behind the header tube plates — undetected by routine plant monitoring.

Targeted Repair: Cleaning, Coating, and Tube Liners

Grit Blasting and Advanced Coating Application

Curran focused initially on the west-end headers where the issue was reported. Using dry abrasive grit blasting, technicians cleaned the tubesheets, wrappers, and covers to prepare the surface. They then applied Curran 1500, a cutting-edge two-part, 100% solids epoxy coating formulated for high-temperature immersion service (up to 365°F / 185°C). This organic/inorganic hybrid coating provides long-term corrosion protection in harsh process environments.

Full-Length AL-6XN Tube Liner Installation

Due to ongoing tube leaks, Curran installed full-length AL-6XN stainless steel liners using a hydraulic expansion method. This technique ensures a tight, uniform bond between liner and parent tube over the entire length — restoring tube integrity without removal.

An Unexpected Leak Discovery and Resolution

Pressure testing after repairs revealed leaks in the east-end header, which had never been detected by plant personnel. The sealing of west-end headers and liner installation allowed these previously hidden defects to be located and repaired. This comprehensive approach prevented further benzene escape, protecting both the environment and refinery workers.

Why Choose Curran for Heat Exchanger Integrity and Leak Repairs?

- Expert inspection and testing services identify hidden leaks and corrosion before they escalate

- Advanced coating technologies provide durable protection in high-temperature, corrosive process streams

- Proven tube liner installation restores tube condition with minimal downtime

- Solutions tailored to EPA compliance and personnel safety requirements

Contact Curran International for Heat Exchanger Leak Solutions

If you have concerns about the integrity of your heat exchangers or need expert assistance with inspection, coating, or repair, contact Curran’s experienced professionals for peace of mind and compliance assurance.

David Grimes

Phone: 513.222.1501

Email: dgrimes@curranintl.com