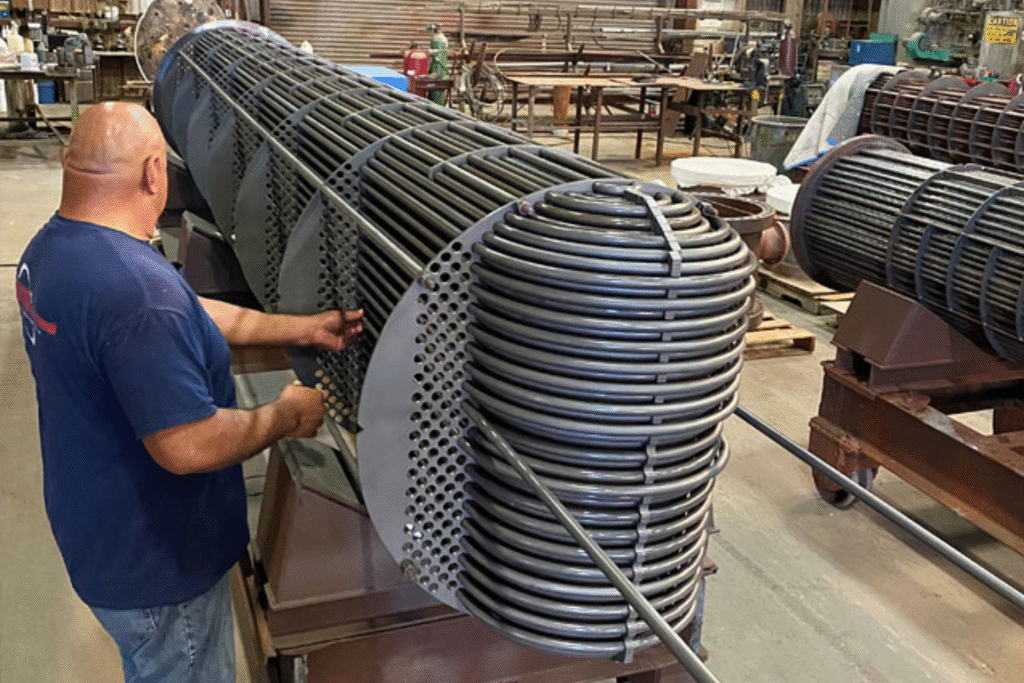

Curran International is redefining heat exchanger coating technology with low-surface-energy thin films that dramatically reduce fouling, extend service life, and sustain heat transfer efficiency in refinery and petrochemical operations.

Why Low Surface Energy Matters

The anti-foul performance comes from applying a low-surface-energy film to the inside of heat exchanger tubes. This increases the fluid contact angle at the tube surface, delivering superior hydrophobic and oleophobic performance.

Compared to uncoated carbon steel, Curran Coatings reduce surface energy by more than three times. Over time, this performance gap widens — while uncoated tubes accumulate oxides and precipitates that raise surface tension up to six times higher than when new, coated tubes maintain their clean, low-energy surfaces. The result: less fouling, fewer hydro-lance cleanings, and longer operational runs.

Thin Film, Maximum Impact

Curran’s coatings are applied in ultra-thin films (just 5–38 microns) to preserve thermal performance. This makes them ideal for both in-service upgrades and in-kind replacement exchangers where maximum heat-transfer is critical.

Engineered for Harsh Conditions

Refinery and petrochemical plants can select from Curran Thin Film Coatings designed for all cooling water sources and hydrocarbon streams, withstanding temperatures up to 750°F. These preceramic polymer coatings deliver high thermal stability and chemical resistance for:

- FCCU Feed

- Vacuum Bottoms

- Crude Pre-Heat Exchangers

- Feed Effluent Exchangers

- Crude Stabilizer Feed Bottoms

Proven Operational Gains

Results speak for themselves:

- 36 months of continuous operation achieved where annual cleaning was previously required.

- Heat transfer performance sustained over time, extending run times three times longer than uncoated steel.

With 25+ coated process-critical exchangers installed at major refineries worldwide, Curran’s portfolio includes silicone, ceramic, and hybrid coatings for carbon steel, stainless steel, CuNi, and titanium alloys.

Complete Anti-Fouling & Corrosion Solutions

Curran’s low-surface-energy portfolio complements its cooling water exchanger tube coating line, including Curran 1000T, a high-performance epoxy that combines durable corrosion protection with proven anti-foul performance.

📩 Contact: Alex Barre, General Manager, Curran International

📧 abarre@curranintl.com | ☎ 281.339.9993