Executive Summary

This case study details how Curran International’s specialized coating technology transformed the performance of critical cooling water exchangers in a refinery’s Fluid Catalytic Cracking (FCC) unit. What began as a reliability improvement project resulted in significant operational efficiency gains across multiple parameters, delivering substantial value beyond the initial corrosion prevention objective.

Client Challenge

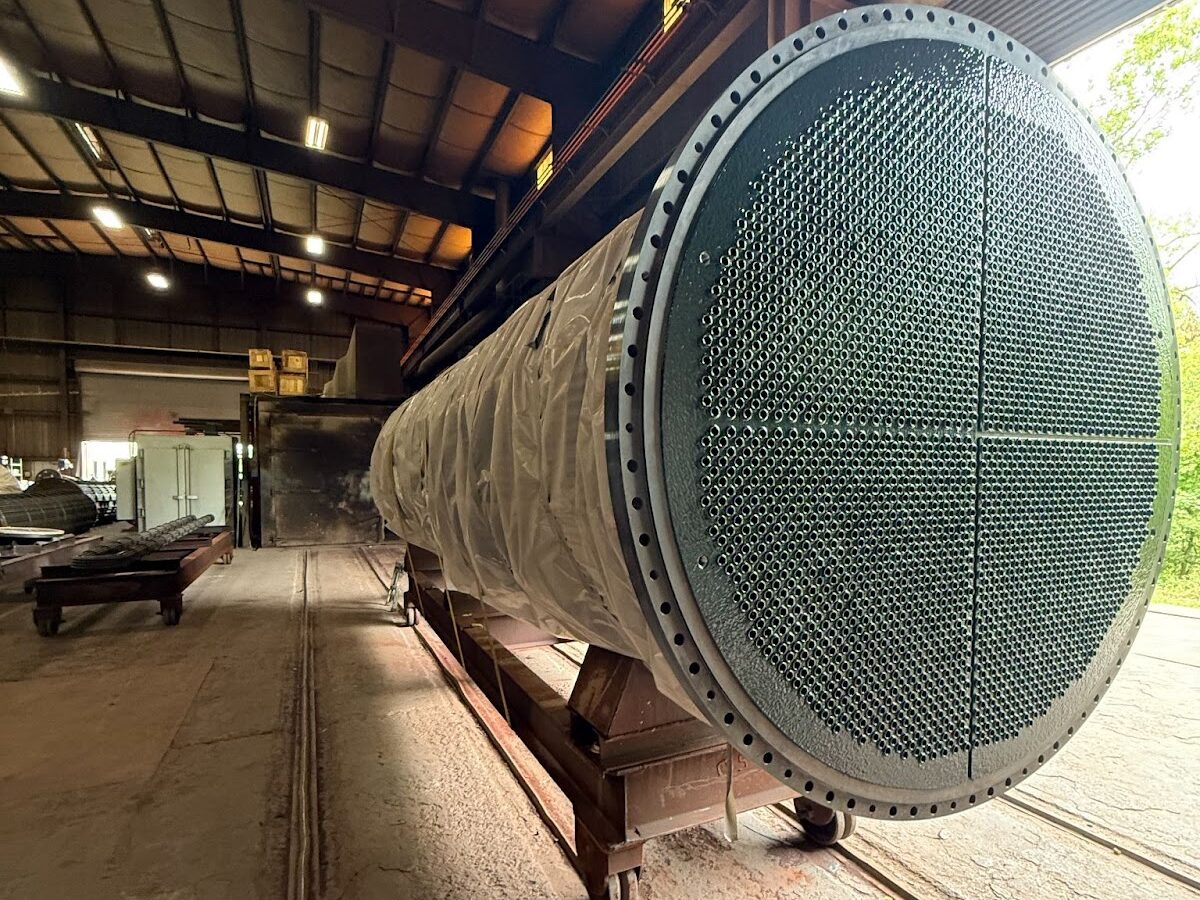

A major refinery operator was experiencing performance limitations in their FCC unit due to cooling water constraints. The refinery already had positive experiences with Curran’s coating solutions, having previously applied them to over 120 exchangers throughout their facility. The FCC unit engineer identified six critical cooling water exchangers where corrosion and fouling were affecting performance:

- Four Main Column Overhead Trim Condensers (Z413-S08 G/H/E/F)

- Two HP Receiver Overhead Trim Condensers (Z414-S02 E/F)

The initial goal was straightforward: reduce corrosion and fouling on the cooling water side of these exchangers to extend equipment life and maintain reliable performance. Like many clients, the refinery initially approached Curran International’s coatings as primarily a corrosion prevention solution.

Technical Solution

Curran International applied their 1000T coating to the cooling water side of the critical FCC exchangers. The implementation was carried out in phases:

- Main Column Overhead Trim Condenser (Z413-S08 G/H) – November 23-30, 2017

- Main Column Overhead Trim Condenser (Z413-S08 E/F) – December 4-15, 2017

- HP Receiver Overhead Trim Condenser (Z414-S02 E/F) – December 26, 2017 to January 4, 2018

The coating service addressed several technical issues simultaneously:

- Eliminated cooling water side corrosion

- Reduced fouling tendency by creating a smooth, low-friction surface

- Maintained or improved heat transfer efficiency

- Enhanced fluid flow characteristics through the exchanger tubes

Results and Benefits

The application of Curran’s specialized coating delivered remarkable improvements far beyond the initial corrosion prevention goals. Comprehensive data analysis revealed significant operational enhancements:

1. Substantial Cooling Water Flow Improvements

The coating resulted in dramatic increases in cooling water flow through the treated exchangers:

| Exchanger ID | Flow Before Coating (m³/hr) | Flow After Coating (m³/hr) | % Increase |

| Z413-S08 G/H | 4,916 | 5,851 | 19% |

| Z413-S08 E/F | 4,858 | 5,851 | 20% |

| Z414-S02 E/F | 4,932 | 5,851 | 19% |

Overall, the net cooling water increment at the ZFCC cooling water header increased by approximately 950 m³/hr, with the total cooling water flow rate increase in all three exchangers reaching approximately 1,250 m³/hr after Curran coating. This improvement occurred while running five cooling water pumps (with one pump out for maintenance).

2. Enhanced FCC Process Performance

The improved cooling water flow unlocked several operational benefits:

- Increased Reactor Temperature: Operators gained the ability to increase reactor temperature by 7-8°C, reaching 545-548°C at 215 KBPSD while still respecting unit constraints including:

- WGC interstage pressure limits

- LV010 change over

- Reg Secondary Cyclone Velocity limits

- Reduced Propylene Loss: Propylene loss in fuel gas was dramatically reduced to less than 1%, even at higher fuel gas levels and increased reactor temperatures, improving overall propylene yield.

- Improved Condensation Performance: The Main Column Receiver (Z413-V03) showed improved condensation at reduced Main Column Overhead pressure (2.35 kg/cm² G) with WGC suction pressure at 1.81 kg/cm² G at the higher reactor temperature.

3. Lower Energy Consumption

The project delivered meaningful energy savings:

- Reduced HP Steam Consumption: Despite operating at higher reactor temperatures, the wet gas compressor steam consumption decreased significantly:

- December 1, 2017: ROT @ 548°C; WGC-1/2 steam consumption @ 130/129 TPH

- December 30, 2017: ROT @ 547°C; WGC-1/2 steam consumption @ 121.5/121.1 TPH

This reduction was attributed to improved condensation and improved gas concentration hydraulic limitation.

4. Process Optimization

The Curran coating in the HP receiver overhead trim condenser (Z414-S02) directly improved:

- Tail end pressure for maximum stripper overhead pressure limits

- Absorption capacity in the primary absorber by maximizing operating pressure

Financial Impact

While the case study does not include specific financial calculations, the multiple areas of improvement translate to significant financial benefits:

- Increased Throughput Capability: The ability to operate at higher reactor temperatures enables potential throughput increases.

- Improved Product Yields: Reduced propylene loss translates directly to increased saleable product.

- Energy Savings: Lower HP steam consumption reduces operational costs.

- Extended Equipment Life: Reduced corrosion and fouling improves reliability and reduces maintenance expenses.

- Deferred Capital Expenditure: Avoiding or delaying the need for cooling water system upgrades or replacements.

Client Testimonial

“The Curran coating not only prevents fouling and corrosion of the tubes but also provides a significant increase in process efficiencies. The coating results in:

a) No fouling and hence no reduction in heat transfer efficiencies

b) No reduction in cooling water flow as there is no fouling

c) No corrosion of tubes

d) Significant reduction in heat exchanger cleaning times during shutdown

All the above advantages pay back the cost of coating…It is requested to consider this coating technique at your sites.”

– Head of Corrosion and Inspection – Fixed Equipment and Piping for 35+ years at Major India Refinery

Future Optimization Potential

Curran’s fluid flow simulation modeling services identified additional optimization opportunities. The design cooling water flow rate for the system is 7,500 m³/hr, compared to the post-coating achieved flow of approximately 5,851 m³/hr.

Further improvements could be realized through:

- Pump assessment and potential rebuilding or replacement of degraded pumps

- Pigging or replacement of cooling water main headers to remove accumulated solids

With these additional measures, even greater performance improvements could be possible:

| Exchanger ID | Flow Before Coating (m³/hr) | Potential Flow After Coating + Further Optimization (m³/hr) | Potential % Increase |

| Z413-S08 G/H | 4,916 | 7,500 | 53% |

| Z413-S08 E/F | 4,858 | 7,500 | 54% |

| Z414-S02 E/F | 4,932 | 7,500 | 52% |

Conclusion

This case study demonstrates how Curran International’s specialized coating technology delivers value far beyond simple corrosion protection. By addressing fouling and flow restrictions in critical cooling water exchangers, the coating enabled substantial operational improvements throughout the FCC unit, including:

- Net gain of 950 m³/hr from the cooling water network

- Increased reactor operating temperature by 7-8°C

- Dramatically reduced propylene losses

- Improved absorption capacity in the primary absorber

- Enhanced condensation at reduced overhead pressures

- Reduced HP steam consumption despite higher operating temperatures

- Improved overall FCC performance with propylene losses consistently below 1%

The project demonstrates that strategically applied specialty coatings can deliver process improvements that significantly exceed the initial reliability objectives, unlocking hidden value in existing equipment.