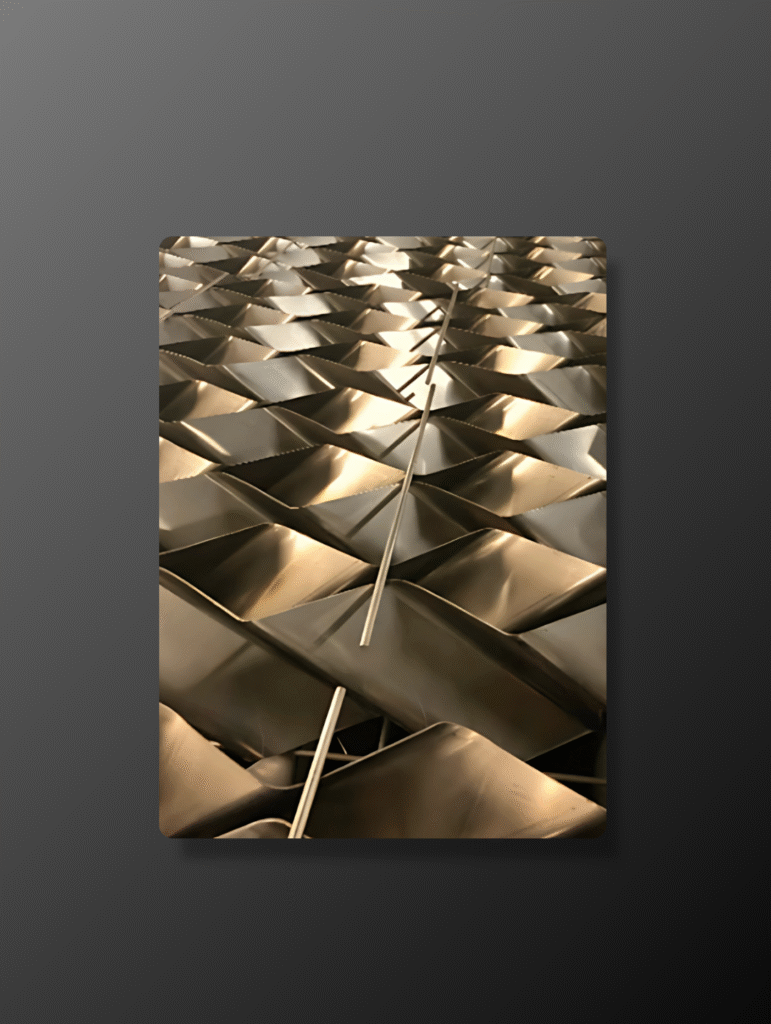

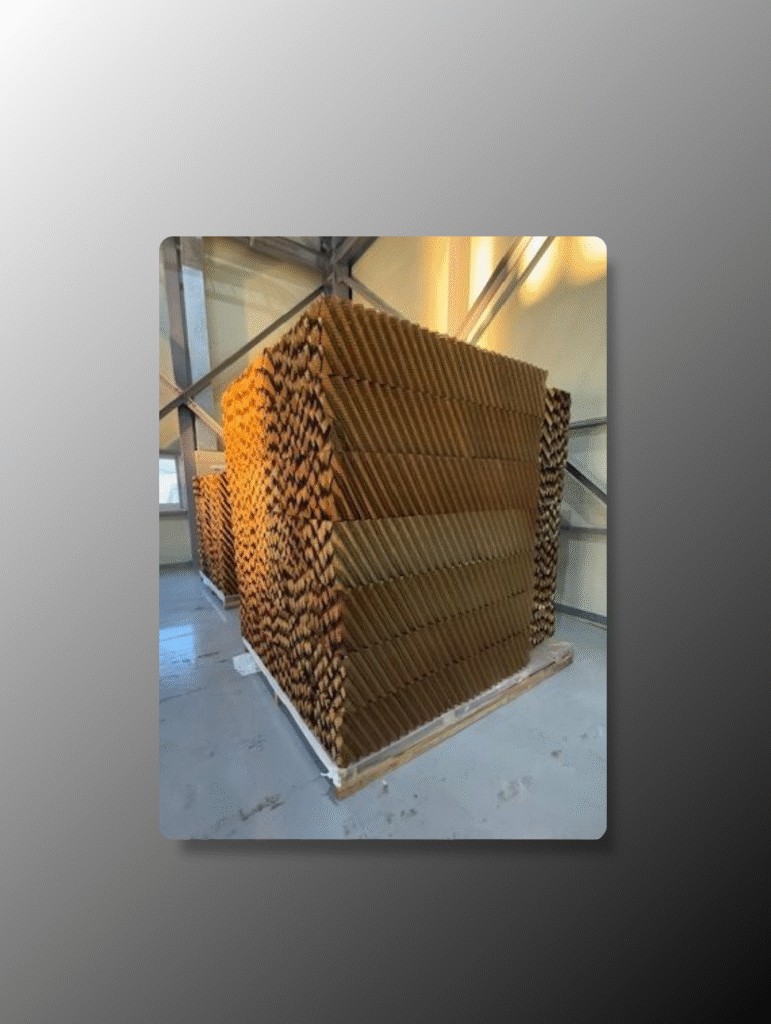

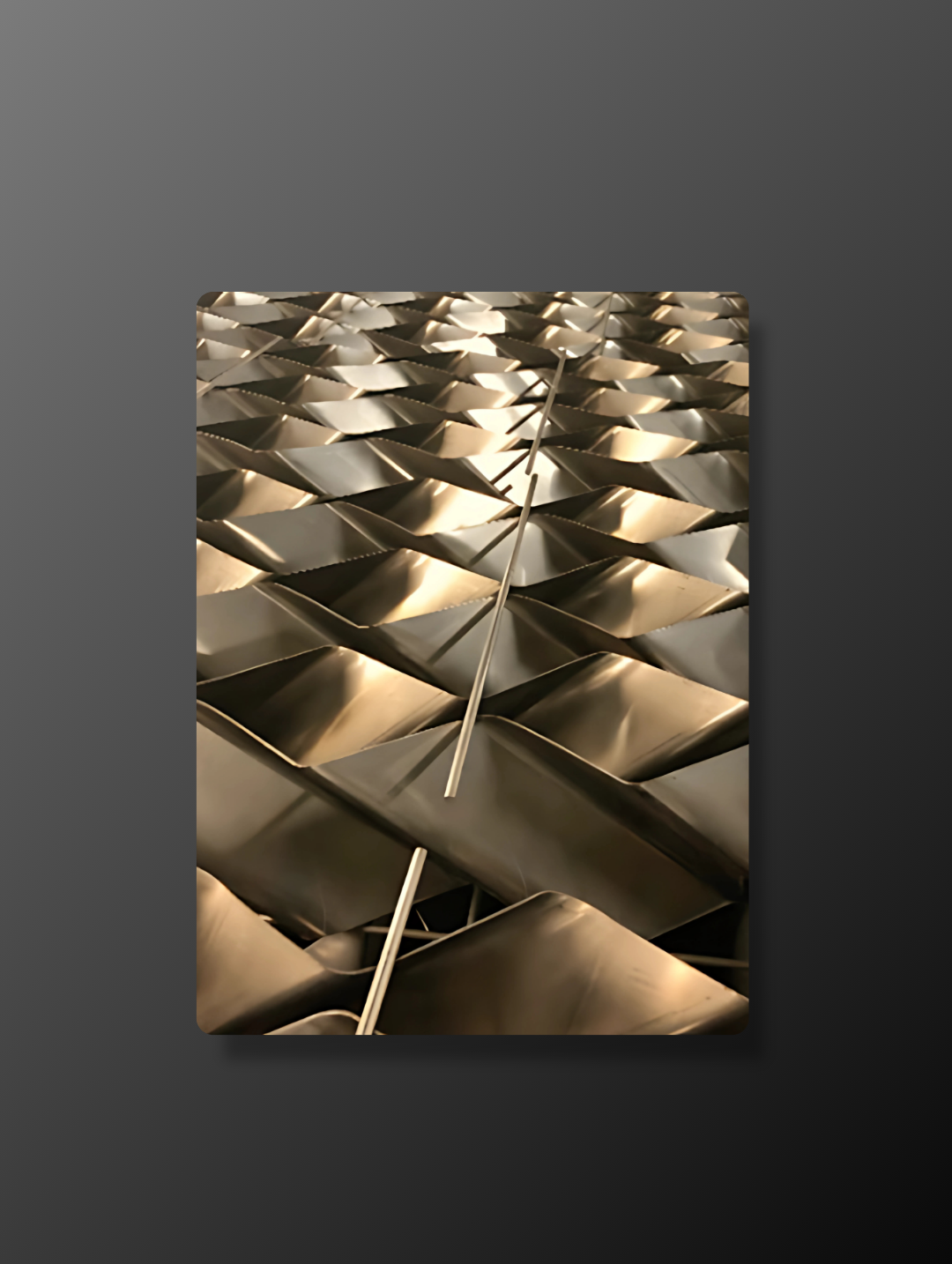

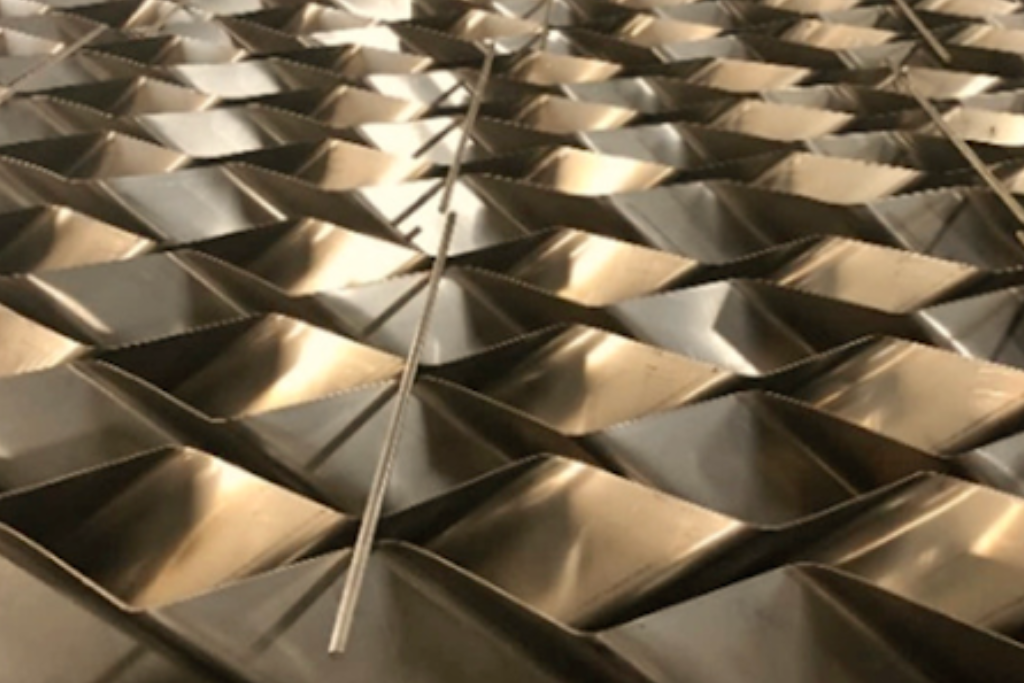

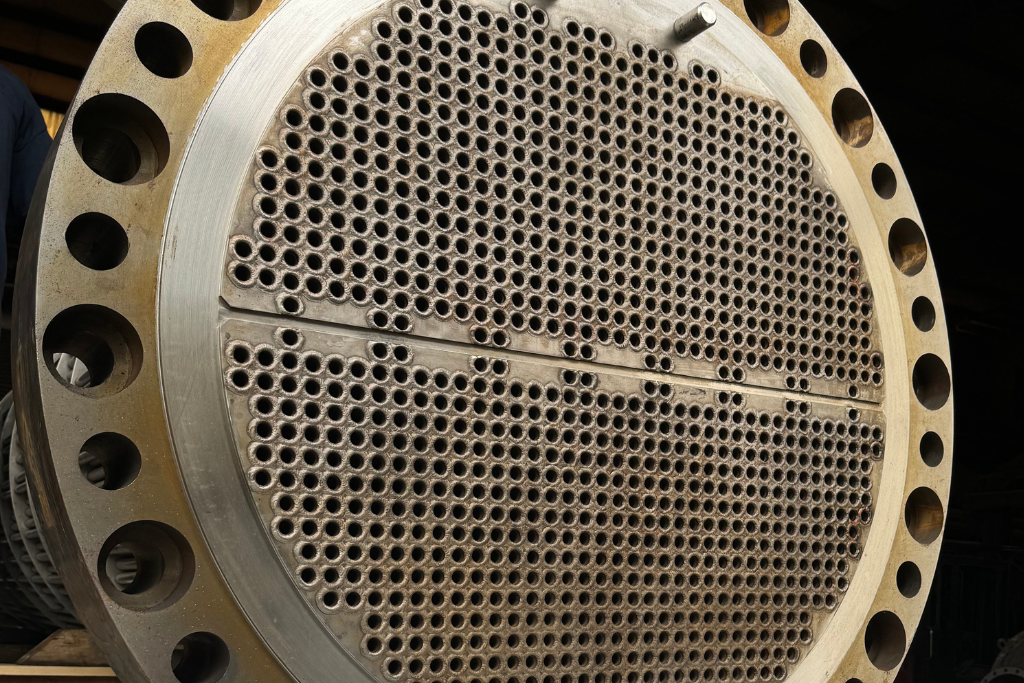

Rare Earth Oxide Surface Treatment streamlines maintenance by making fouling easier to remove—reducing cleaning time, water usage, and labor costs. Its slick, durable surface allows for rapid foulant release, even after extended service runs. Unlike traditional coatings that degrade under pressure, REO Surface Treatment withstands aggressive cleaning, including up to 20,000 PSI hydroblasting, without loss of integrity. When cleanings are necessary, they are faster, more effective, and far less disruptive—saving time and cutting turnaround costs.