For decades, utilities and power plant owners have accepted a frustrating reality: hiring multiple contractors to maintain their tubular heat transfer equipment. One company provides heat exchanger cleaning services, another handles testing and inspection, and yet a third implements repairs and corrective actions.

This fragmented approach costs you more time, more money, and unfortunately, often delivers less than satisfactory results.

The Problem with Multiple Contractors

We’ve seen it countless times – equipment owners struggling with the same challenges:

Communication Nightmares

Managing multiple project teams creates a logistics and communication headache for your project managers. Different crews, different schedules, different standards – it’s a recipe for confusion and delays.

Finger-Pointing When Issues Arise

When problems occur during any phase of the project, you’re suddenly caught in the middle of contractors blaming each other. Nobody takes full responsibility, and you’re left managing the chaos.

Higher Costs and Extended Timelines

Multiple mobilizations, separate project management fees, and coordination delays add up quickly. What should be a streamlined maintenance project becomes an expensive, drawn-out ordeal.

Our Solution: Complete Turnkey Heat Exchanger Maintenance

For over three decades, we’ve eliminated these problems by being your one-source solution. Here’s how our integrated approach works:

Mixed Expert Teams

Our crews combine mechanical specialists and NDE (non-destructive examination) experts who work together on every project. These aren’t separate teams coordinating – they’re integrated professionals who’ve collaborated for years and know exactly what each phase requires.

Comprehensive Service Portfolio

We handle every aspect of your heat exchanger cleaning services, inspection, and repair needs:

- Condenser tube cleaning using advanced tube ID grit blasting techniques

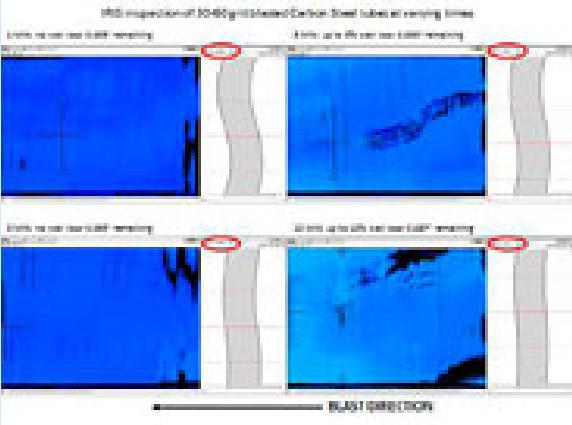

- Complete NDE inspection services including Eddy Current, Remote Field, Near Field, IRIS, and Eddy Current Array

- Heat exchanger coating with our proprietary thin film protective coating systems

- Industrial tube sheet coating for long-term protection

- All necessary mechanical repairs and corrective actions

Technology Independence

Unlike equipment manufacturers tied to specific products, we’re a service company with the freedom to choose the best method for your equipment’s unique needs. This flexibility ensures optimal heat exchanger cleaning services tailored to your specific requirements.

The Predictive Maintenance Advantage

We don’t just clean and repair – we track and analyze your equipment’s performance trends. This data-driven approach enables predictive maintenance for heat exchangers that:

- Prevents problems before they impact performance through early intervention

- Increases system uptime by addressing issues proactively

- Enhances equipment longevity through strategic maintenance timing

- Improves heat transfer performance consistently over time

Why Our Integrated Approach Delivers Superior Results

Seamless Project Flow

When your entire project team has worked together for years, there are no handoff delays or miscommunication gaps. Each specialist knows what’s expected and when, creating smooth project execution from start to finish.

Single Point of Accountability

You have one contact for the entire work scope. No more managing multiple relationships or trying to determine who’s responsible when questions arise.

Optimized Resource Utilization

Our integrated crews eliminate redundant mobilization costs and maximize efficiency through coordinated work planning.

Consistent Quality Standards

Every phase of your project follows the same rigorous quality standards and customer satisfaction commitment, ensuring consistent results across all services.

Proven Results Across Three Decades

Our comprehensive approach consistently delivers:

- Reduced overall project costs compared to multi-contractor approaches

- Shorter project timelines through streamlined coordination

- Higher quality outcomes from integrated team expertise

- Improved equipment reliability through coordinated maintenance strategies

- Better long-term performance from our predictive maintenance tracking

Our Commitment to Your Success

When you entrust your turnkey heat exchanger maintenance to our team, you transfer the complexity from your project managers to our skilled technicians. We handle the coordination, communication, and quality control so you can focus on what matters most – keeping your plant running efficiently.

Our experience spans numerous power plant condenser repair projects and industrial heat exchanger applications worldwide. This expertise, combined with our comprehensive service capabilities, makes us your ideal single-source partner for all tubular heat transfer equipment needs.

Ready to Simplify Your Next Heat Exchanger Project?

Experience the difference of working with one team, one point of contact, and one commitment to excellence. Our integrated approach to heat exchanger inspection, cleaning, and coating services eliminates the headaches of multi-contractor management while delivering superior results.

Contact us at (281) 339-9993 or dgrimes@curranintl.com to discuss your upcoming maintenance projects. Visit our website to download our comprehensive service brochure and learn more about our complete heat exchanger solutions.

With over 35 years of experience serving power plants and industrial facilities worldwide, we continue to prove that one source truly means one job well done.