When carbon steel valves must operate in highly corrosive fluid service, standard materials often fall short of providing reliable, long-term performance. PFA fluoropolymer coatings offer superior resistance to corrosive environments that would quickly compromise mild steel components.

We’ve been applying these specialized protective coatings for more than 14 years, developing the expertise needed to achieve homogenous protective films that serve as effective corrosion-resistant barriers.

Understanding PFA Fluoropolymer Coating Technology

PFA (Perfluoroalkoxy) fluoropolymer coatings are engineered for exceptional chemical resistance in applications where conventional coatings fail. These advanced coating systems:

- Resist aggressive chemical attack that degrades standard protective coatings

- Form homogenous protective films when properly applied and cured

- Provide long-term barrier protection against corrosive fluid contact

- Maintain integrity in service conditions that destroy conventional materials

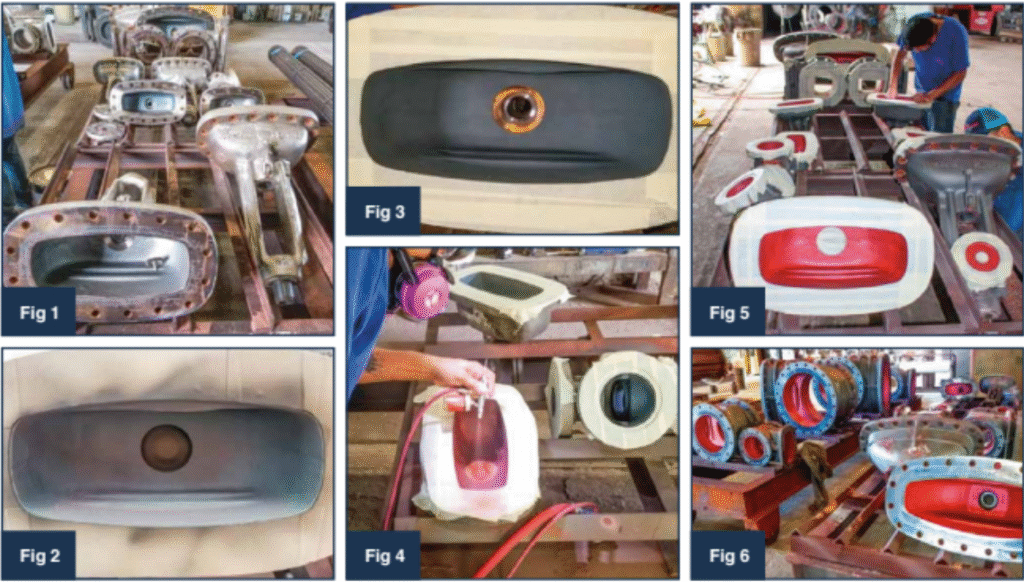

Recent Project: Gate Valve Coating for Refinery Service

A recent project completed in our facility demonstrates the comprehensive approach required for successful PFA coating applications in critical industrial service.

Project Specifications and Requirements

A refinery client specified PFA coating application for a series of gate valves designed for corrosive fluid service. The project parameters included:

- Carbon steel valve construction requiring enhanced corrosion protection

- PFA coating specification added to improve service life expectations

- Stainless steel pipe connections to the coated valve assemblies

- Unassembled valve delivery from OEM for coating application

Critical Pre-Application Assessment

Before any coating work begins, comprehensive substrate evaluation is essential:

Visual Inspection Protocol

- Weld uniformity assessment on new fabrication components

- Excess splatter identification and removal requirements

- Overall component quality evaluation for coating suitability

Chemical Contamination Testing

- Machining lubricant testing to identify cleaning requirements

- Soluble chloride testing on substrate surfaces

- Surface preparation planning based on contamination findings

Precision Surface Preparation: The Foundation of Success

Strategic Masking and Protection

Following client specifications, gasket seating areas at flanges were masked and protected to maintain critical sealing surfaces while allowing coating application on all other areas.

NACE 1 “White Metal” Standard

All surfaces designated for coating receive grit-blasting to NACE 1 “white metal” cleanliness. This thorough surface preparation:

- Creates optimal anchor profile for coating adhesion

- Removes all surface contaminants that could compromise coating bond

- Provides uniform surface condition across all coated components

The Art and Science of PFA Application

Precision Prime Coat Application

The initial prime coat application at precise thickness is essential to coating system success. This critical first layer:

- Establishes proper foundation for subsequent coating builds

- Ensures uniform coverage across complex valve geometries

- Creates chemical bond with prepared substrate surface

Skilled Application Technique

Our coating technicians use fine spray application methods to achieve optimal coating distribution. The PFA coating system requires exceptional skill because:

- The coating system is delicate and easily applied incorrectly

- Multiple coats are required to reach desired thickness specifications

- Pinhole-free surface must be achieved for effective protection

- Holiday testing verifies coating integrity throughout the process

Controlled Curing: Critical for Long-Term Performance

High-Temperature Cure Requirements

The PFA system requires heat cure at 650°F with each coating application. Our large convection oven accommodates batched loads of components while maintaining precise temperature control.

Time-Critical Curing Process

The curing cycle demands patience and precision:

- More than 24 hours of controlled heat-up and cool-down cycles

- Gradual temperature ramping prevents coating delamination

- No acceleration possible – rushing the process causes coating failure

- Complete restart required if coating delaminates from improper heating

Quality Control Throughout Curing

Each curing cycle includes:

- Dry film thickness verification to meet specification requirements

- Holiday testing to confirm pinhole-free coating integrity

- Visual inspection for any signs of coating defects or delamination

Final Protection: Release Top Coat Application

After multiple base coat applications pass all specification requirements, a specialized “release” top coat is applied. This final protective layer:

- Reduces adhesion of corrosive scales to coated surfaces

- Prevents deposit buildup that could compromise long-term performance

- Provides additional chemical barrier for enhanced protection

- Maintains smooth surface finish for optimal fluid flow characteristics

Why PFA Coating Expertise Matters

Complex Application Requirements

Successful PFA coating requires:

- Specialized equipment including high-temperature ovens

- Skilled technicians experienced with fluoropolymer application

- Comprehensive quality control throughout multi-step process

- Understanding of failure modes and prevention strategies

Long-Term Performance Benefits

Properly applied PFA coatings deliver:

- Superior corrosion resistance in aggressive chemical service

- Extended valve service life reducing replacement frequency

- Reduced maintenance requirements through enhanced chemical protection

- Improved system reliability in critical process applications

Applications Beyond Gate Valves

Our 14+ years of PFA coating experience extends across multiple industrial applications:

- Process equipment components in chemical service

- Pipe fittings and connections requiring corrosion protection

- Instrumentation housing in corrosive environments

- Custom fabricated components designed for aggressive service

Comprehensive Fluoropolymer Coating Services

PFA represents just one option in our complete range of fluoropolymer coating capabilities. Different applications may benefit from other fluoropolymer systems, each with specific advantages for particular service conditions.

Technical Consultation Available

Our coating specialists can help determine:

- Optimal coating system for your specific service conditions

- Application requirements and timeline considerations

- Quality control standards appropriate for your application

- Long-term performance expectations based on service environment

Ready to Enhance Your Equipment’s Corrosion Resistance?

When standard materials and coatings aren’t sufficient for your corrosive service applications, specialized PFA fluoropolymer coatings provide proven protection that extends equipment life and improves reliability.