Watching your heat exchanger performance decline tube by tube is frustrating and expensive. Every time another tube fails and gets plugged, you’re not just losing capacity – you’re accelerating the failure of remaining tubes and moving closer to costly equipment replacement.

There’s a better approach than the endless cycle of plugging failed tubes.

Why Tube Failure is Inevitable (But Manageable)

From day one of operation, your heat exchanger tubes face relentless attack from multiple sources:

- Erosion from high-velocity fluids wearing away tube walls

- Corrosion from aggressive chemicals and temperature cycling

- Mechanical stress from thermal expansion and vibration

- Fouling deposits that accelerate localized corrosion

The standard response – plugging failed tubes – seems logical but creates a cascade of problems:

The Plugging Spiral

As you plug more tubes, several detrimental effects compound:

- Thermal performance suffers proportionally to plugged tube percentage

- Inlet velocities increase in remaining tubes, accelerating erosion

- Heat transfer efficiency drops, forcing harder operation of remaining equipment

- Premature failures accelerate due to higher stress on fewer tubes

Eventually, you reach the point where plugging percentage necessitates complete retubing or heat exchanger replacement – an expensive reality that proper tube protection could have prevented.

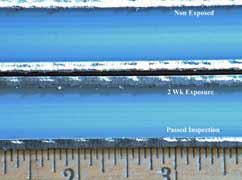

Solution 1: Thin-Film Tube ID Protective Coatings

Our thin-film tube ID coating process transforms vulnerable bare metal tubes into protected, high-performance assets that deliver years of additional reliable service.

Our Proprietary Preparation Process

Success starts with proper surface preparation using our proprietary tube ID grit blasting process:

- Complete removal of all contaminants and active corrosion cells within tube IDs

- Elimination of scale buildup that compromises heat transfer

- Creation of optimal anchor profile for superior coating adhesion

Advanced Coating Application Method

Our specialized application process ensures comprehensive protection:

- Compressed air propulsion drives coating applicators through complete tube length

- Superior capillary action forces coating into cracks, pits, and small through-wall holes

- Protective barrier formation seals defects and prevents further degradation

- Boundary release properties prevent fouling buildup between maintenance cycles

Performance Benefits You’ll Measure

Coated tubes consistently deliver:

- Extended service life with additional years of reliable operation

- Cleaner running between planned outages and turnarounds

- More efficient cleaning during routine maintenance activities

- Renewable protection – coatings can be reapplied as needed years later

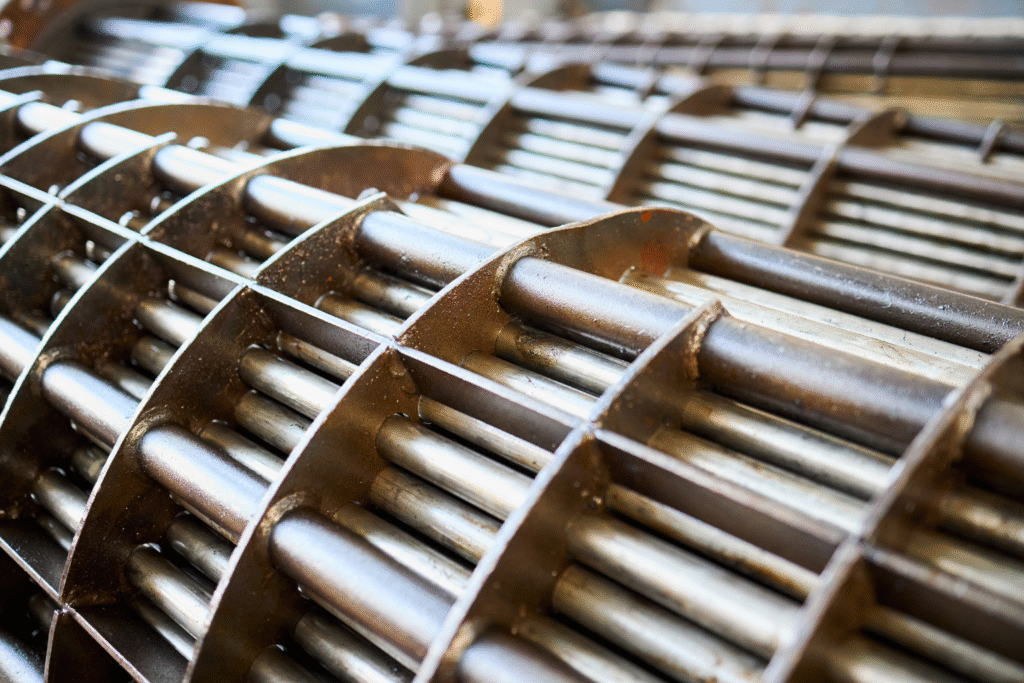

Solution 2: Hydraulic Tube Liners and Sleeves

For tubes with significant wall loss, cracking, or through-wall defects, our hydraulic tube liner installation provides complete structural restoration.

Comprehensive Tube Preparation

Proper preparation is critical for liner success:

- Patented tube ID grit blasting removes all scale and contaminants completely

- Bare metal restoration eliminates insulating deposits between liner and parent tube

- Quality assurance inspection ensures cleanliness before liner installation

Why Thorough Cleaning Matters

Other companies often use high-pressure water lancing, which leaves scale remnants that:

- Reduce thermal heat transfer by trapping insulating deposits

- Create premature liner failures through hot spots and trapped corrosion cells

- Compromise performance by preventing complete metal-to-metal contact

Professional Hydraulic Expansion Process

Our installation method ensures optimal performance:

- 100% metal-to-metal contact through complete hydraulic expansion

- Full-length expansion eliminates air gaps and insulation effects

- Precise trimming and flaring for proper tube sheet integration

- Thin-wall construction (.028″ or less) minimizes velocity and heat transfer impacts

Material Selection Expertise

We help you choose the optimal liner material for your specific environment:

- Erosion-resistant stainless steel for high-velocity applications

- Corrosion-resistant alloys for aggressive chemical environments

- Application-specific materials matched to your operational conditions

Repair Capabilities That Restore Full Function

Our hydraulic liner process can successfully repair:

- Tubes with excessive wall loss from corrosion or erosion

- Cracked or pitted tubes with structural integrity issues

- Through-wall defects that compromise tube function

- Multiple tube problems in comprehensive restoration projects

The Economics of Proactive Protection

Before defaulting to tube plugging, consider the long-term costs:

Traditional Plugging Approach

- Immediate capacity loss with each plugged tube

- Accelerated failure of remaining tubes

- Declining efficiency and increasing operating costs

- Eventual complete equipment replacement

Proactive Protection Investment

- Extended equipment life with years of additional service

- Maintained thermal performance through protected tubes

- Reduced maintenance frequency and improved reliability

- Deferred replacement costs while maximizing asset value

Our Commitment to Your Success

Our objective is simple: help you maximize the performance and reliability of your tubular heat transfer equipment. Whether through thin-film protective coatings or hydraulic liner installation, both services go a long way toward achieving this goal.

Don’t wait until your next tube failure forces another plugging decision. Let our professionals evaluate whether proactive tube protection makes sense for your specific performance and reliability challenges.

Contact us at (281) 339-9993 or reach out to David Grimes at dgrimes@curranintl.com to discuss your tube protection options. Our team can assess your current situation and recommend the most effective approach for extending your heat exchanger investment.

With decades of experience in tube protection and restoration, we’ve helped facilities worldwide avoid premature equipment replacement through proactive tube protection strategies.