PTFA/PFE is a high-performance fluoropolymer coating system engineered to prevent corrosion and scaling in heat transfer equipment and vessels operating in severe hydrocarbon and corrosive environments.

This PTFE coating technology delivers robust protection to assets subject to aggressive chemical and corrosive environments. Applicable to tanks, vessels, piping, heat exchangers, and beyond.

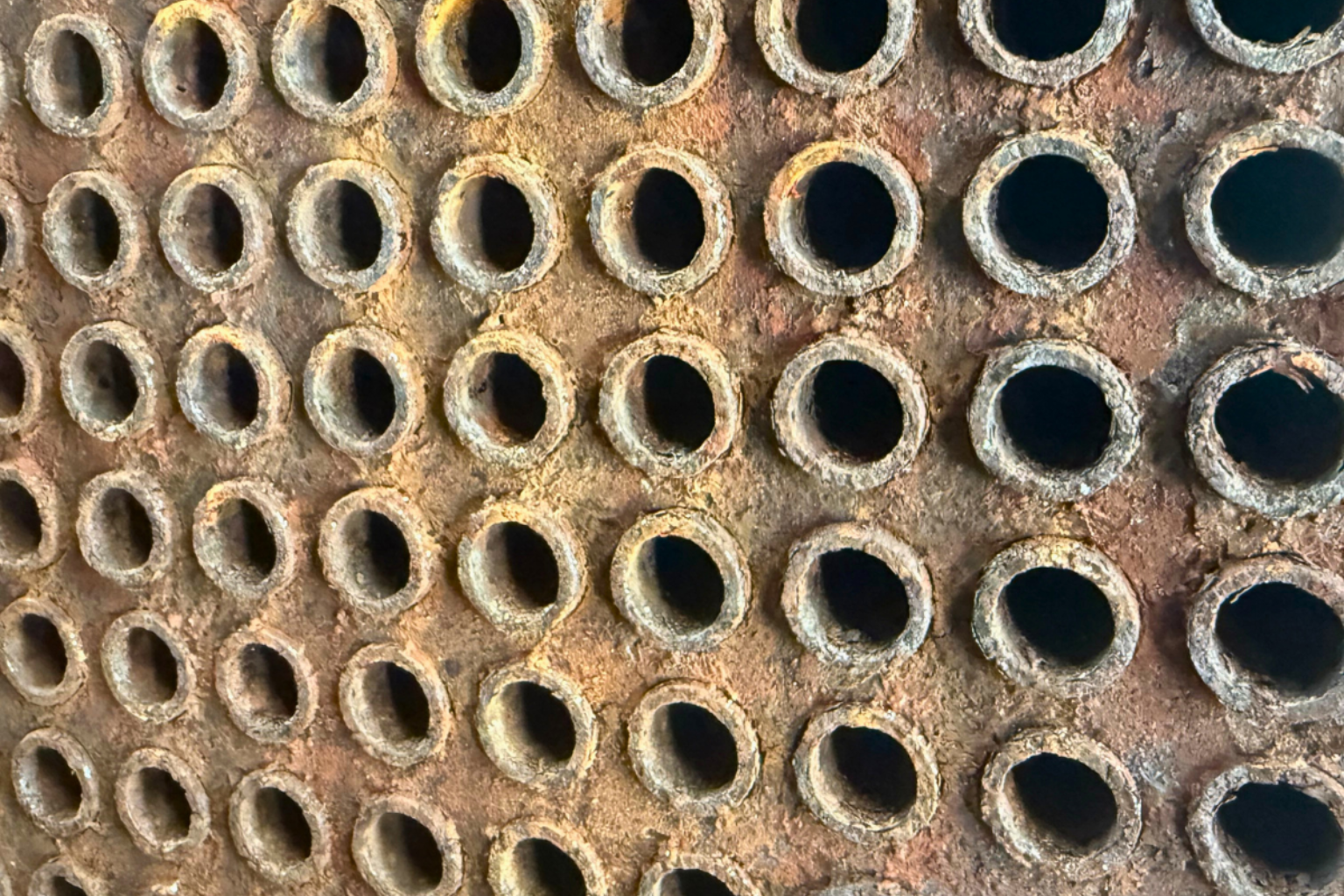

Heat exchangers in hydrocarbon processing face relentless fouling from mineral scale, viscous crude, and organic deposits, forcing frequent shutdowns and costly cleaning cycles.

Reduction in heat transfer efficiency

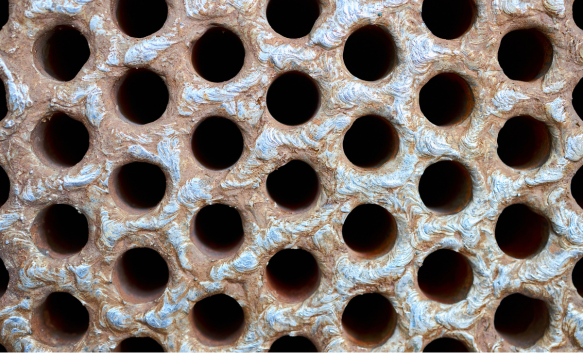

PTFA/PFE fluoropolymer technology creates a non-stick barrier that resists corrosion and enables easy removal of deposits with low-pressure water cleaning.

Design duty performance maintained

Provides outstanding protection against harsh chemicals, including acids, bases, and solvents. Its non-reactive barrier prevents corrosion and surface degradation, even in aggressive environments, helping extend equipment life and reduce maintenance needs.

Non-stick surface properties enable easy deposit removal with low-pressure water hoses, eliminating aggressive chemical cleaning requirements.

Maintains its mechanical and chemical integrity across a wide temperature range, performing reliably in both high-heat and cryogenic conditions. This makes it ideal for systems exposed to thermal cycling or extreme process temperatures.

Lower cleaning costs, reduced chemical usage, and extended equipment life deliver substantial cost savings per exchanger unit.

Acts as a highly effective barrier against gas and liquid penetration, making it ideal for sealing and lining applications where containment and leak prevention are critical.

Continuous operation at temperatures up to 500°F (260°C) for demanding thermal applications.

Proven performance in the world's most challenging heat exchanger applications

| Equipment | Heat exchangers handling recycled condensate for well injection, yielding crude and bitumen |

| Challenge | Severe fouling in down-tube sections due to mineral scaling and viscous crude causing frequent cleaning cycles required to maintain performance |

| Solution | PTFA/PFE applied to heat exchanger tubes to reduce fouling and improve performance using Curran’s proprietary application process |

| Results |

|

Proven performance in the world's most challenging heat exchanger applications

Canadian Oil Sands • Major Refinery • Active •

| Equipment | Heat exchangers handling recycled condensate for well injection, yielding crude and bitumen |

| Challenge | Severe down-tube fouling required frequent cleanings. |

| Solution | PTFA/PFE applied for fouling control |

Partner with Curran International for advanced anti-corrosion coating technology

01

PTFA/PFE is a Generation 2 fluoropolymer coating system specifically engineered for extreme anti-fouling performance in hydrocarbon environments. Unlike conventional coatings, it provides exceptional resistance to mineral scale, viscous crude, and organic deposits while maintaining non-stick properties that enable easy cleaning.

02

PTFA/PFE is designed for continuous operation at temperatures up to 500°F (260°C), making it suitable for high-temperature heat exchanger applications in refining and oil sands operations.

03

Field evaluations demonstrate PTFA/PFE performance for 16+ months without decline in heat transfer efficiency. Service life depends on specific operating conditions and maintenance practices.

04

Yes, PTFA/PFE can be applied to both new fabrication and used equipment. The coating works on the interior surfaces of heat exchanger tubes, tubesheet, and channel areas.

05

PTFA/PFE's non-stick properties allow for easy cleaning with low-pressure water hoses. However, avoid caustic cleaners with pH greater than 10 and do not use hydroblasting, as this may remove the coating.

06

Yes, PTFA/PFE is extensively used in Steam-Assisted Gravity Drainage (SAGD) sites for produced water coolers, where it drastically reduces fouling from residual clays, free oil, and organic deposits.

07

PTFA/PFE uses Curran's proprietary application method in a controlled shop environment. The coating system includes a primer, midcoat, and topcoat that must be properly cured using controlled

Please enter your name and email.

We’ll email the data sheets shortly.