For decades, Curran tube-ID coatings have protected cooling water exchanger tube bundles from corrosion, delivering long-term reliability and significant cost savings. Recent projects highlight the value these coatings provide in extending exchanger life and reducing maintenance costs.

Louisiana Refinery – 14 Years of River Water Service

A Gulf Coast refinery had a 304 stainless steel exchanger operating with river water cooling. Originally, tube IDs and tubesheets were coated with Curran. After 14 years of service, the exchanger was pulled for replacement:

- Passed a hydro test

- No tube degradation observed in reliability inspections

The refinery performed restoration work, including:

- Curran cleaning and removal of the old coating

- ECT and IRIS NDE inspections

- Recoating with a new Curran tube-ID coating

Inspection results showed no defects, confirming the longevity and protective quality of Curran coatings.

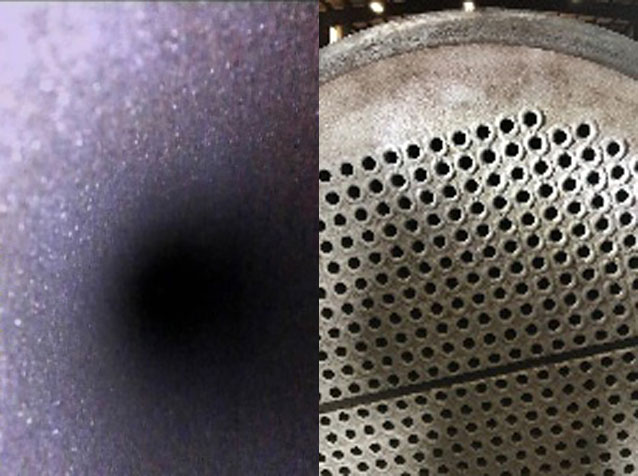

Texas Refinery – Coated vs. Uncoated Comparison

Two floating-head exchangers, installed in 2011, operated on the same cooling water circuit. Only one exchanger was coated with Curran tube-ID coating. Both were pulled in 2020 for cleaning and IRIS NDE.

Observations after cleaning:

- Coated tube: Maintained a smooth, defect-free ID

- Uncoated tube: Showed generalized surface corrosion along the tube ID and tubesheet

These images demonstrate how Curran coatings protect tube bundles, preventing corrosion and extending service life—even when operating under identical conditions.

A Long-Term Value-Add

- Curran tube-ID coatings have been used as a cost-effective protective measure for carbon steel and stainless steel exchangers for over 30 years

- Coatings allow for extended runtimes, fewer cleanings, and reduced unplanned maintenance

- Gulf Coast refineries continue to rely on Curran coatings as a proven solution for long-term exchanger protection

Curran Tube-ID Coating – A Proven History

Epoxy and baked phenolic coatings have a long-standing track record in mitigating corrosion and fouling in refinery and petrochemical operations. These durable, thin-film coatings provide:

- Superior adhesion

- Homogeneous finish

- An inert barrier against cooling water ionic exchange

Curran Coatings are tested for immersion service up to 365°F, making them suitable for most cooling water systems.

Optimized Protection for All Alloys

Cooling water scaling and corrosion have historically challenged crude and petrochemical manufacturing. Curran’s tube-ID coatings provide targeted protection:

- Carbon steel: Downtube coatings applied pinhole-free at 8–12 mils

- Less reactive alloys (stainless steel, copper-nickel, titanium): Coating applied at <4 mils

Even with inherently corrosion-resistant alloys, Curran’s thin-film coatings optimize fouling release, reducing the need for cleaning and preventing premature tube failure.

A Proven Track Record

Curran International began full-length tube coating in 1991 as part of an Electric Power Research Institute (EPRI) evaluation project. The goal: salvage steam condenser tubes suffering early pitting and failure.

- In-situ application demonstrated the effectiveness of Curran’s coatings

- Since then, Curran has developed high-performance epoxy coatings for 365°F immersion service across nearly all cooling water systems

Figures:

- Figure 1: Formerly coated exchanger and tubesheet after Curran cleaning and coating removal for IRIS NDE

- Figure 2: Uncoated exchanger and tubesheet after Curran cleaning for IRIS NDE

Learn More

To explore Curran International’s proven heat exchanger coatings:

🌐 Curran Heat Exchanger Protective Coatings

📞 281.339.9993

Catch Curran Live

Meet the Curran team and learn how they reduce failures, extend equipment life, and improve thermal transfer worldwide:

- API 2022 Inspection and Mechanical Integrity Summit – Henry B. Gonzalez Convention Center, San Antonio, TX, August 9–11, 2022

- AMPP 2023 Annual Conference + Expo – Colorado Convention Center, Denver, CO, March 19–23, 2023