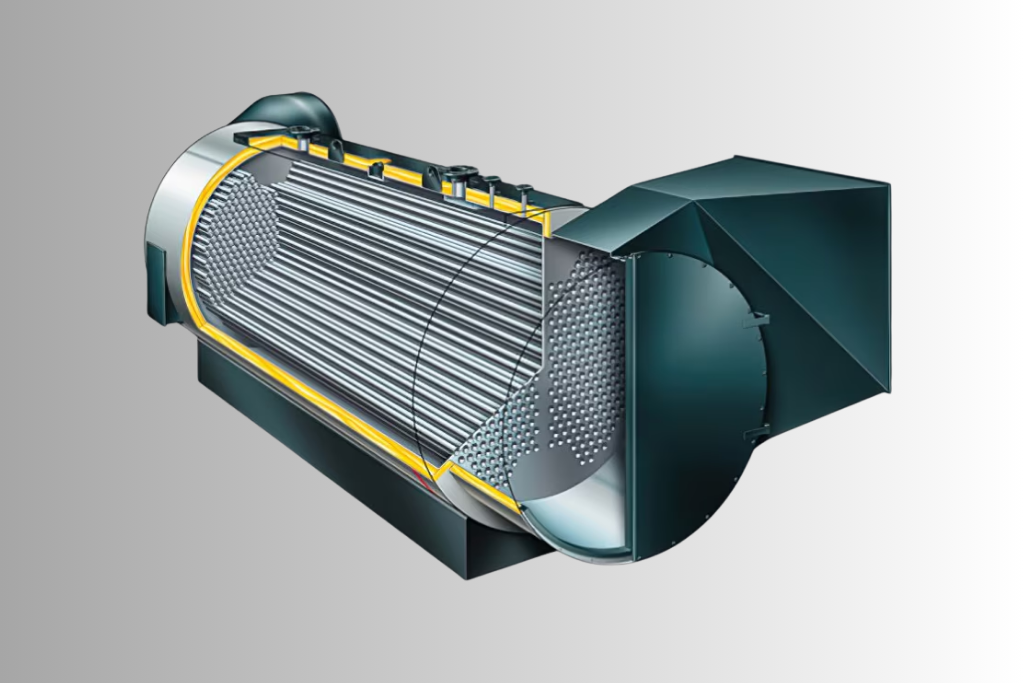

Curran’s SRU Cleaning is a specialized dry abrasive cleaning service for sulfur recovery unit exchangers, including Claus boilers, waste heat boilers, tail gas units, and condensers. This waterless cleaning method removes sulfur-based deposits and corrosion products from tube IDs, enabling accurate NDE inspections while protecting refractory materials from moisture damage.

SRU exchangers face severe fouling from sulfur compounds and corrosion products. Traditional hydro blasting introduces moisture that damages refractory and creates operational delays.

Hydro Pressure Still Ineffective

Dry grit blasting completely removes deposits while protecting refractory integrity. Tubes are inspection-ready immediately after cleaning with no drying time required.

Scale Removal Achievement

Curran’s dry cleaning method eliminates moisture-related delays and refractory damage while delivering superior tube cleanliness. This enables accurate integrity assessments and extends equipment run lengths between turnarounds.

No water introduction prevents costly refractory damage and eliminates drying delays

Achieve cleanliness levels required for advanced NDE methods previously impossible with hydro blasting

Immediate inspection readiness with no drying period required

Complete scale removal prevents under-deposit corrosion

Restore thermal efficiency by removing insulating deposits

Clean tubes reduce pressure drop and flow restrictions

Discuss your SRU cleaning requirements

Define equipment and turnaround schedule

Deploy specialized crews and equipment

Complete cleaning with quality verification

01

Our waterless process eliminates moisture introduction, preventing refractory damage and avoiding costly drying delays that can extend turnaround schedules.

02

Our high-velocity grit removes sulfur compounds, iron sulfide scale, corrosion products, and other tenacious deposits that resist traditional cleaning methods.

03

Yes, we have specialized procedures for U-tube cleaning with careful attention to inner radius dwell times to prevent through-wall damage.

04

Cleaning times vary by exchanger size, but our predictable per-tube cleaning rates allow accurate scheduling, typically completing bundles in 1-3 shifts.

05

Our calibrated dwell times and controlled process parameters ensure safe cleaning across all common SRU metallurgies including carbon steel, stainless steel, and exotic alloys.

Please enter your name and email. We’ll be in touch soon.