Advanced Hybrid Materials Deliver Maintenance Savings

Curran International has partnered with material formulators to develop advanced foul-release coatings for plate and frame exchangers (PFEs). Using sol-gel based hybrid materials, these coatings were initially demonstrated on offshore crude production platforms, showing significant reductions in fouling and cleaning requirements.

Field Trials Show Fewer Cleaning Events

Client data confirms the value of coated PFEs. In low-temperature (60°C) crude oil and water separators, coated exchangers extended uninterrupted service from 6 months to 3 years. In other trials, fouling was reduced by 30% over 32 weeks between maintenance intervals. Curran has established procedures to apply these coatings globally at OEM service depots, enabling plate disassembly, cleaning, and maintenance before coating.

Lower Maintenance Costs and Improved Efficiency

These thin-film coatings reduce surface tension (<30 dynes/cm²) and surface roughness (Ra ~0.05 microns), improving release performance at the plate substrate. Longer maintenance intervals lead to measurable operational efficiency gains and reduced annual maintenance costs. Sol-gel coatings are applied at 5–15 microns on stainless steel, aluminum, titanium, and Inconel plates, creating a smooth, low-energy surface that does not significantly impact heat transfer.

Key Benefits:

- Hydrophobic and oleophobic performance

- Optimized release at the fluid-substrate interface

- Minimized product attachment and fouling

- Improved shear under normal operating conditions

Why Clean PFEs Matter

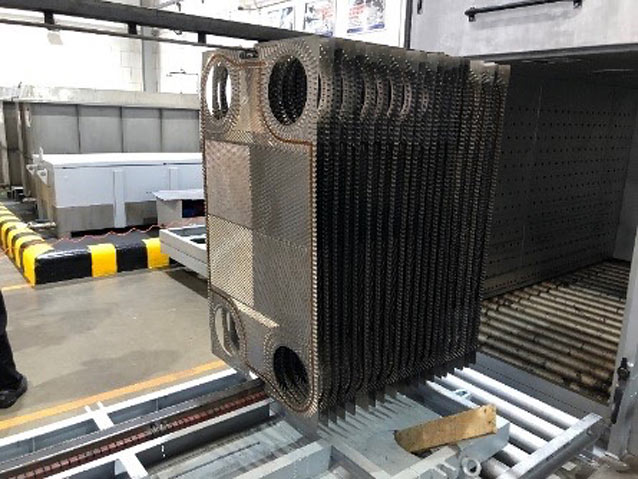

PFEs are widely used where space is limited—offshore platforms, food and dairy processing, and chemical operations. Their compact design and high turbulence make them efficient, but also prone to fouling in the 2–4 mm channels between plates. Cleaning may be performed on-line or through full disassembly, often at OEM depots where plates are cleaned, gaskets replaced, and reassembled.

Curran Expertise in Anti-Foul Coatings

Curran applies coatings at OEM depots or field locations. In-service plates are disassembled, cleaned, and prepped for coating. Gasketed areas are protected during coating application, which is fully cured prior to reassembly. Testing with a Dyne pen confirms that coated surfaces maintain low surface energy (<30 dynes/cm²), ensuring maximum foul-release performance.

Put Curran’s Coatings to Work

Curran’s portfolio of anti-foul coatings and proven application expertise help reduce maintenance, improve exchanger efficiency, and extend service life.

Contact:

Edward Curran – ecurran@curranintl.com | 281.339.9993