Executive Summary

- Client: Major Gulf Coast Petrochemicals & Refining Complex.

- Challenge: The failure of multiple conventional cleaning methods—including 20,000 PSI hydroblasting and offsite ultrasonic cleaning—to prepare a critical U-tube exchanger for a required IRIS inspection during a time-sensitive turnaround.

- Solution: Expedited, off-site tubular grit blasting at Curran International’s specialized Dickinson, TX facility.

- Result: Extended the asset’s reliable service life by over two years, avoiding the immediate and significant capital expenditure for a replacement bundle.

During a critical plant turnaround, a major petrochemical producer faced significant delays when conventional methods like 20k PSI hydroblasting failed to clean a U-tube exchanger for a vital IRIS inspection. By leveraging Curran International’s specialized grit blasting technology, the bundle was cleaned to a perfect, inspection-ready standard in just five days. This rapid and effective solution provided the client with precise data on the asset’s condition, allowing them to confidently return it to service and defer a major capital investment.

The Challenge: When Conventional Cleaning Creates Costly Delays

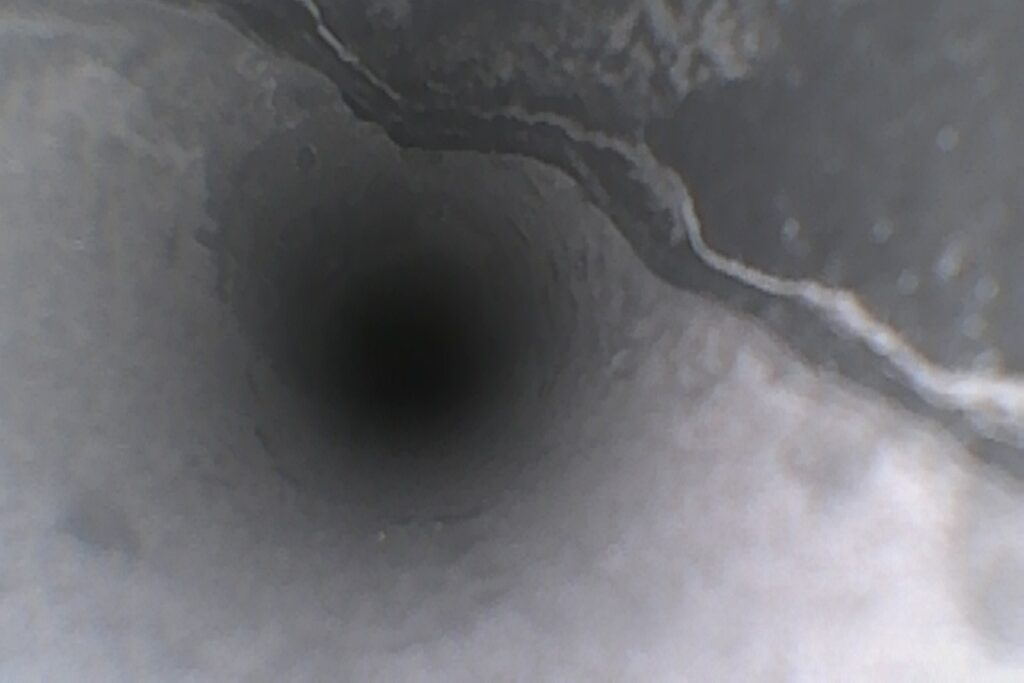

The operational challenge was significant. Tenacious, hard-baked deposits inside the 334 U-tubes were impervious to their standard cleaning protocols. First, onsite high-pressure (20k PSI) hydroblasting and mechanical scrapers failed to remove the stubborn tube scale. A second attempt, sending the bundle for offsite ultrasonic cleaning, also fell short of the required cleanliness. With each failed attempt, the turnaround schedule delays mounted, and the risk of a forced, multi-million dollar bundle replacement grew. Without reliable inspection data, the plant was flying blind—forced to choose between running a potentially compromised asset or incurring a massive, unbudgeted capital expense.

[See the Borescope view of the tenacious internal tube deposits that conventional cleaning methods could not remove, preventing accurate inspection.] 👇

The Solution: A Strategic & Methodical Approach

With their primary and secondary cleaning plans exhausted, the client transported the U-tube bundle to Curran International’s dedicated cleaning facility in Dickinson, Texas. Our team immediately recognized why previous methods had failed and deployed a targeted grit blasting strategy.

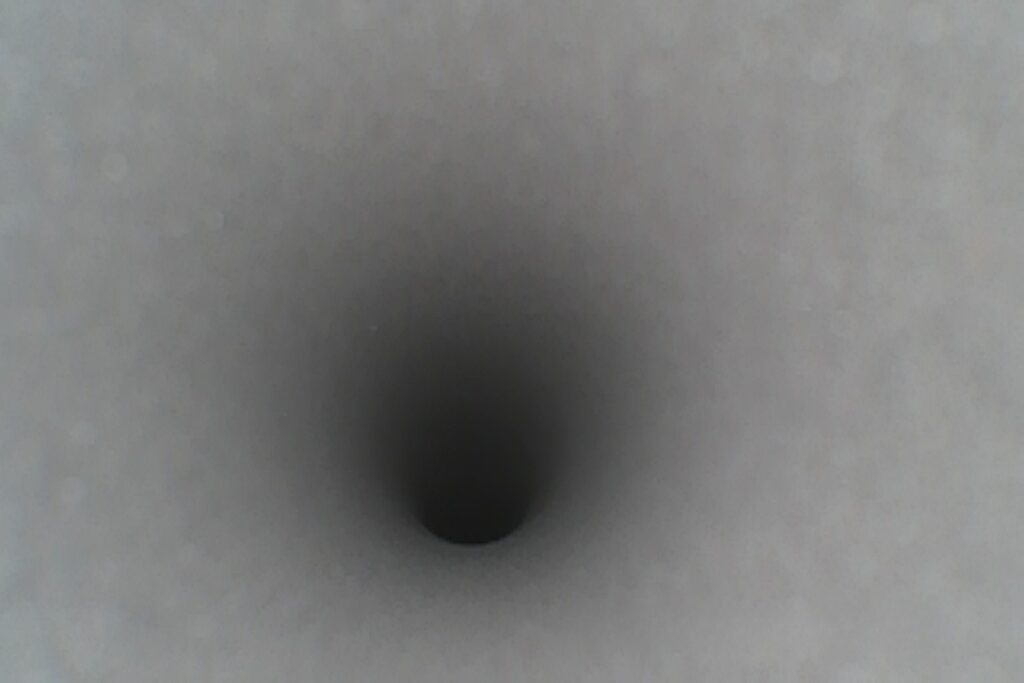

The core issue was the nature of the fouling. While high-pressure water is effective against softer deposits, it lacks the abrasive force to shear away the hard, crystalline scale that had formed within the tubes. Curran’s patented dry tubular grit blasting, however, is engineered for precisely this scenario. It uses a high-velocity stream of dry abrasive (GMA Garnet) to scour the internal tube surface, methodically removing even the most stubborn deposits and corrosion byproducts. This process achieves a near-white metal finish (SSPC-SP5/NACE 1), creating the ideal, artifact-free surface for sensitive IRIS inspections.

Our process was systematic and transparent:

- Receipt & Staging: The bundle was received and carefully staged inside a controlled blast booth, with all critical gasket surfaces masked to protect their integrity.

- Targeted Grit Blasting: Our technicians cleaned each of the 334 U-tubes, carefully controlling the process to avoid any potential damage to the U-bends—a key consideration for this type of exchanger.

- Real-Time Verification: After the initial passes, tube cleanliness was verified using video probes to ensure 100% of the surface area met the stringent IRIS standard, eliminating the guesswork and rework cycles common with other methods.

- Inspection & Handover: Upon completion of cleaning, Curran staged the bundle for the client’s third-party NDT inspectors and provided full support, ensuring a seamless and efficient inspection process.

The entire operation, from the bundle’s arrival to its readiness for inspection, was completed in just five consecutive days, pulling the client’s schedule back on track.

[See the same tube after Curran’s grit blasting process, cleaned to a white metal finish, ready for accurate IRIS inspection.] 👇

Who We Are

At Curran International, we are the industry leader in solving the toughest heat transfer equipment challenges. For over 30 years, we have provided refineries, power plants, and chemical facilities around the world with specialized services for tubular heat exchangers, including proprietary grit blasting, advanced anti-fouling coatings, and expert field services. Our mission is to help our clients improve heat transfer, extend equipment run-time, and reduce maintenance frequency in their most critical assets.

From Inspection Readiness to Performance Gains

This project proved that achieving a 100% clean, inspectable surface is the first step in maximizing asset life. To see another example of how our proprietary cleaning processes restored a severely fouled asset and improved plant performance, explore our Horseshoe Lake Unit 6 Cleaning Study. This detailed analysis showcases how we tackled severe macrofouling in a power plant condenser to restore critical vacuum pressure and efficiency when other cleaning methods couldn’t.

Check it out Here 👉 https://curranintl.com/horeshoe-lake-unit-6-cleaning-study/

P.S.

Are failed cleaning attempts putting your turnaround schedule at risk? Book a 30-minute, no-obligation strategy session Below with our technical team to build a first-pass success plan for your next critical equipment cleaning. 👇