Expert in-situ protective coating applications for condenser waterboxes, channels and vessels with nearly 30 years of global experience. Our 100% solids epoxy systems provide superior protection against corrosion while enhancing operational efficiency.

Our 100% solids epoxy polymeric systems (0 VOCs) provide excellent cathodic protection against corrosive elements.

Enhanced release properties for mineral scale and organic foulants, maintaining optimal system performance.

Withstands thermal fluctuations while maintaining an inert barrier between conductive water and mild steel.

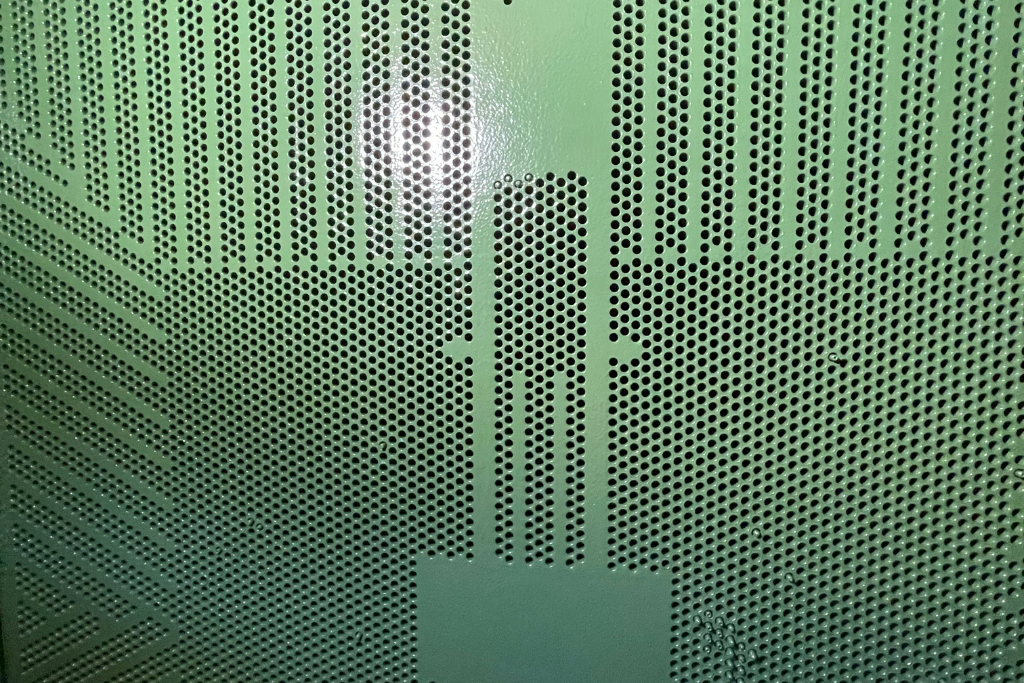

UHP water jet removal of existing coatings, treatment of contaminants, and dry abrasive grit blasting with vacuum dust containment.

Precise humidity and temperature management using dehumidifiers and heaters to ensure optimal application conditions.

Disciplined application with 100% inspection followed by force curing to ensure maximum protection and longevity.

Available in high-build trowel applied material, sprayable versions, and brush and roll coating options to suit various application needs.

Liquid formulation for applications up to 40 mils, with compatible paste grade that can be applied up to 250 mils for maximum protection.

Perfect for condensers, HVAC chiller tube sheets, waterboxes, circulation water piping, channels, and marine boxes.

Withstands water and steam up to 365°F (185°C) with tolerance for excursions/steam outs to +400°F (204°C).

Advanced two-part 100% solids novolac epoxy designed as a brush and roll material for specialized applications.

Specially formulated for exchanger tube sheet coating and tubesheet repairs of previously coated exchangers.

100% solids hybrid novolac epoxy specifically designed to repair corroded steel in challenging service conditions where temperature differentials exist. Provides exceptional resistance in "cold wall" services, protecting steel in hot immersion while outer surfaces may remain uninsulated.

Atlas cell tested for six-plus months in deionized water at 210°F (98°C) and pressurized Atlas Cell tested for 60 days in de-ionized water at 365°F. When fully cured, Curran 1500 becomes a machinable coating suitable for flange repairs and restoration of pitted steel surfaces.

Condensers and heat exchangers

Vessels and marine boxes

Circulation pipes and channels

Restoration of damaged surfaces