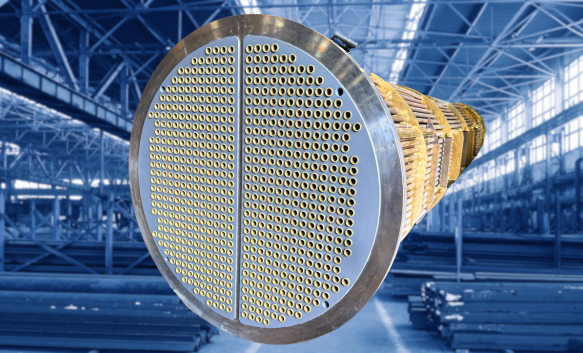

Curran 5100 is an ultra-thin, hydrophobic foul-release coating engineered to combat fouling and corrosion in cooling water systems and harsh industrial environments. This one-part silicone sol-gel coating cures at ambient conditions to form a durable, low surface energy film that prevents deposits from adhering while promoting dropwise condensation, all without impairing heat transfer.

NSF-certified for food contact use, Curran 5100 delivers high-performance fouling protection in industrial heat exchangers, condensers, and process equipment where contamination is not an option.

Heat exchanger lifespan increased by 50% in refinery cooling water streams

Ultra-hydrophobic surface prevents fouling adhesion

Proven thermal stability in high-temperature processes

Cooling water systems accumulate mineral scale, biofilms, and corrosion products that act as insulating barriers, reducing heat transfer efficiency and increasing pressure drop.

Annual industry losses due to fouling

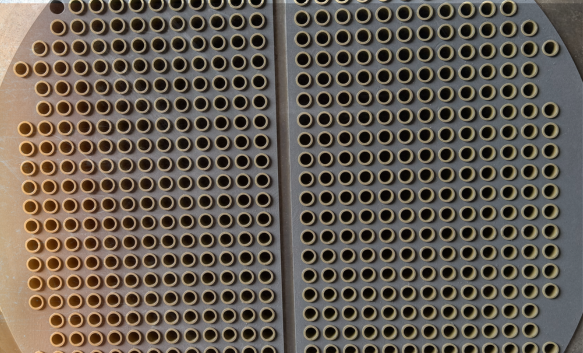

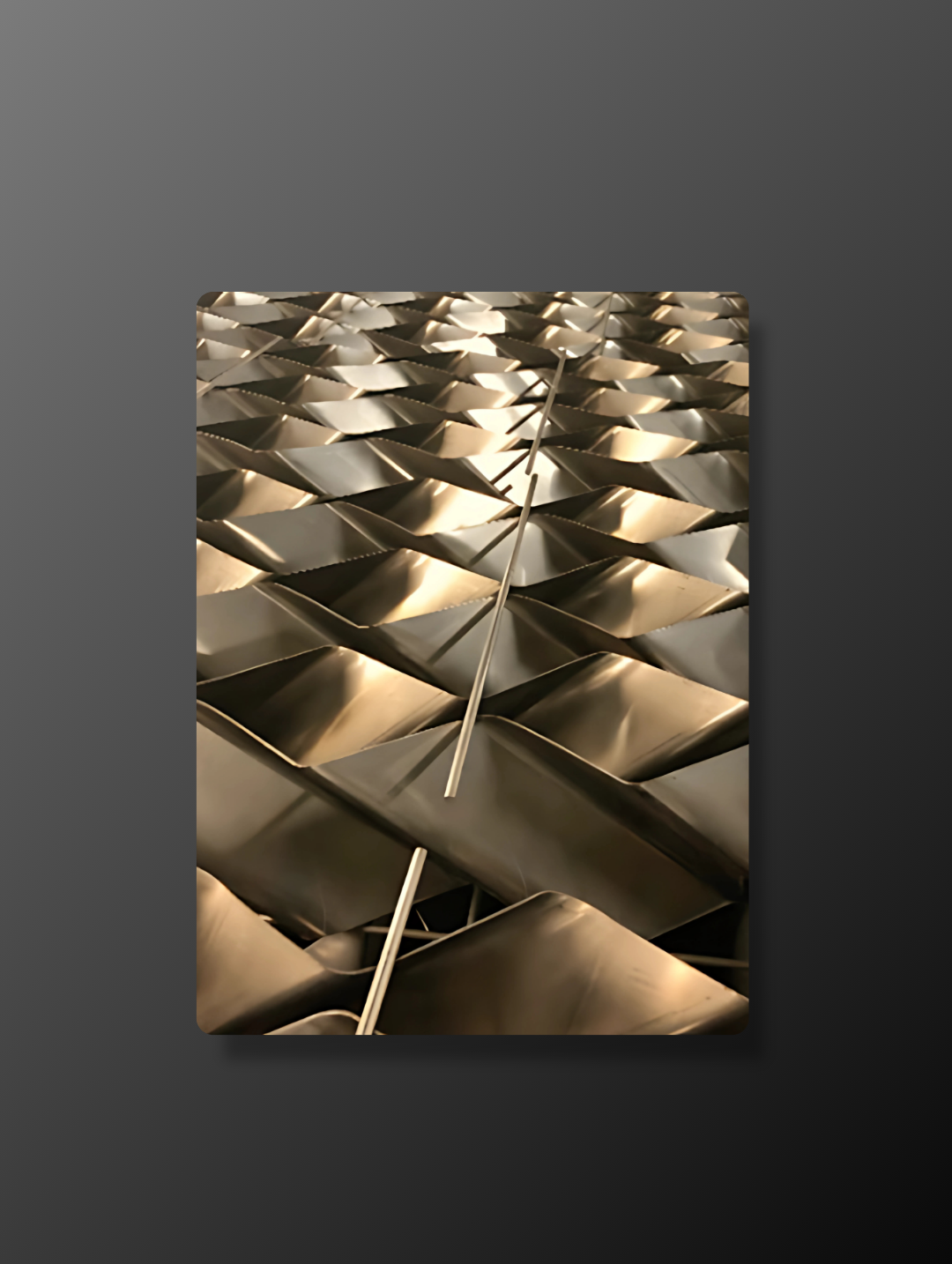

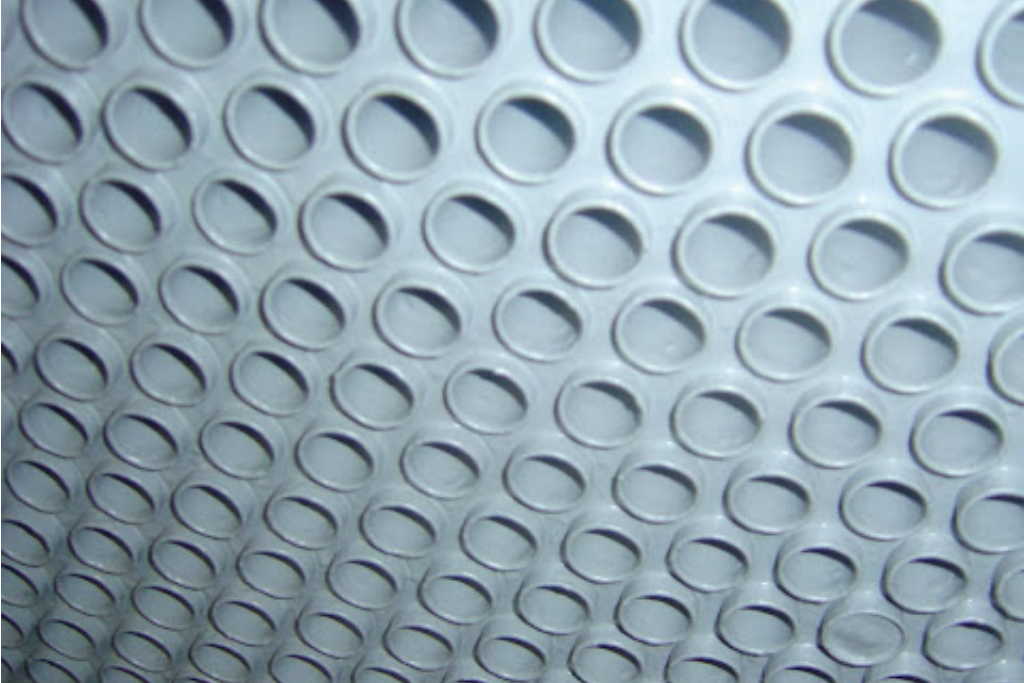

A 5100 application creates a robust, ultra-smooth barrier with 20 mN/m surface energy that dramatically lowers adhesion forces binding foulants to metal.

Higher heat transfer coefficients vs. filmwise condensation

Ultra-smooth, slick surface makes it difficult for scale, algae, and other foulants to get a foothold. Minor films rinse off with low-pressure water rather than requiring aggressive cleaning.

Physical barrier protects base metal from corrosive agents like oxygen, chlorides, or acids. Dual-action protection extends intervals before maintenance or replacement.

Silicone-based coating remains highly flexible (325% elongation). Withstands 180 alternating cycles of 400-500°F dry heat and 180°F water quenching without adhesion loss.

10 – 15 μm thickness adds negligible resistance to heat transfer. Promotes dropwise condensation that can dramatically boost heat flux in condensing applications.

NSF/ANSI 51 certified for direct food contact up to 400°F. Contains no heavy metals, BPA, or PTFE—safe for food processing and pharmaceutical equipment.

Continuous immersion up to 250°F, excursions to 400°F, dry exposure to 500°F

Spray application or injection as low-viscosity liquid (30,000-40,000 cP). Self-leveling for uniform coating.

5 – 7+ years in cooling water environments.

Ultra-thin profile adds negligible thermal resistance.

Ambient cure via moisture.

Excellent unprimed adhesion to bras, nickel, carbon steel, stainless steel, copper alloys, cast iron, glass, ceramic.

Excellent resistance to water, hydrocarbons, moderate acids/alkali. Suitable for high-chloride environments.

Tubes: 10-15 µm;

Sheets/Surfaces: 25-50 µm

Proven solutions for fouling-resistant heat transfer equipment

| Equipment | Hydrotreater preheat exchangers exposed to high-temperature caustic and acidic conditions |

| Challenge | Severe fouling deposits plus corrosive attack from caustic/acid in the process caused frequent cleaning outages and risked tube failure |

| Solution | Curran 5100 applied as a protective barrier on exchanger components and piping |

| Results |

|

| Equipment | Steel tanks storing acids/caustics with interior lining degradation |

| Challenge | Aggressive chemicals were eating away at the tank’s previous lining, leading to material loss and costly repairs. Frequent relining was needed |

| Solution | Curran 5100 applied as an internal tank liner provided a chemical-resistant barrier |

| Results |

|

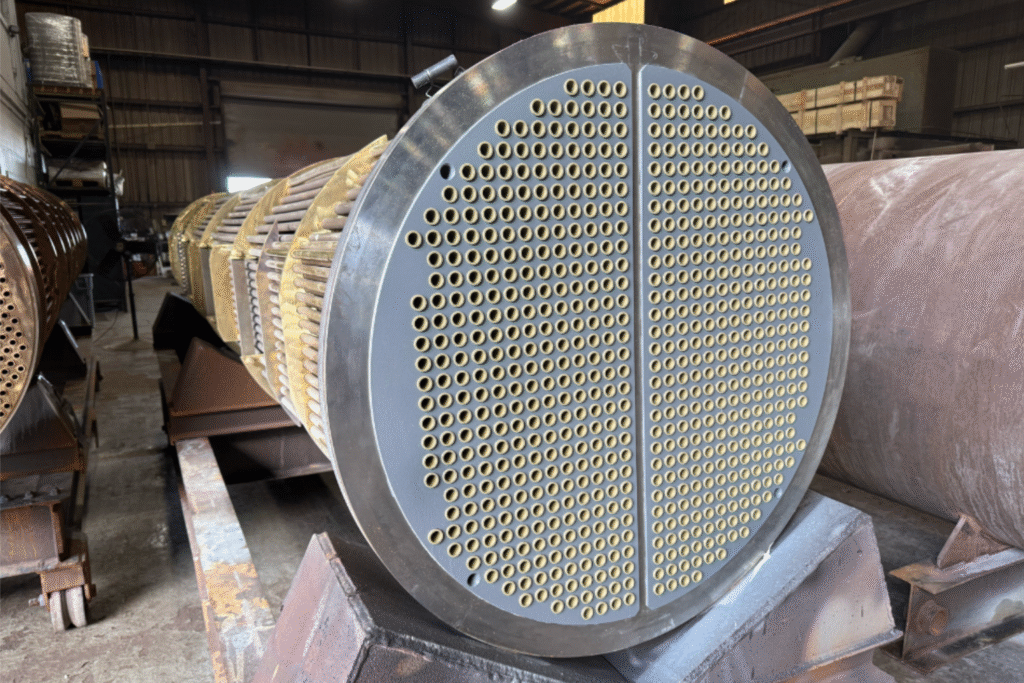

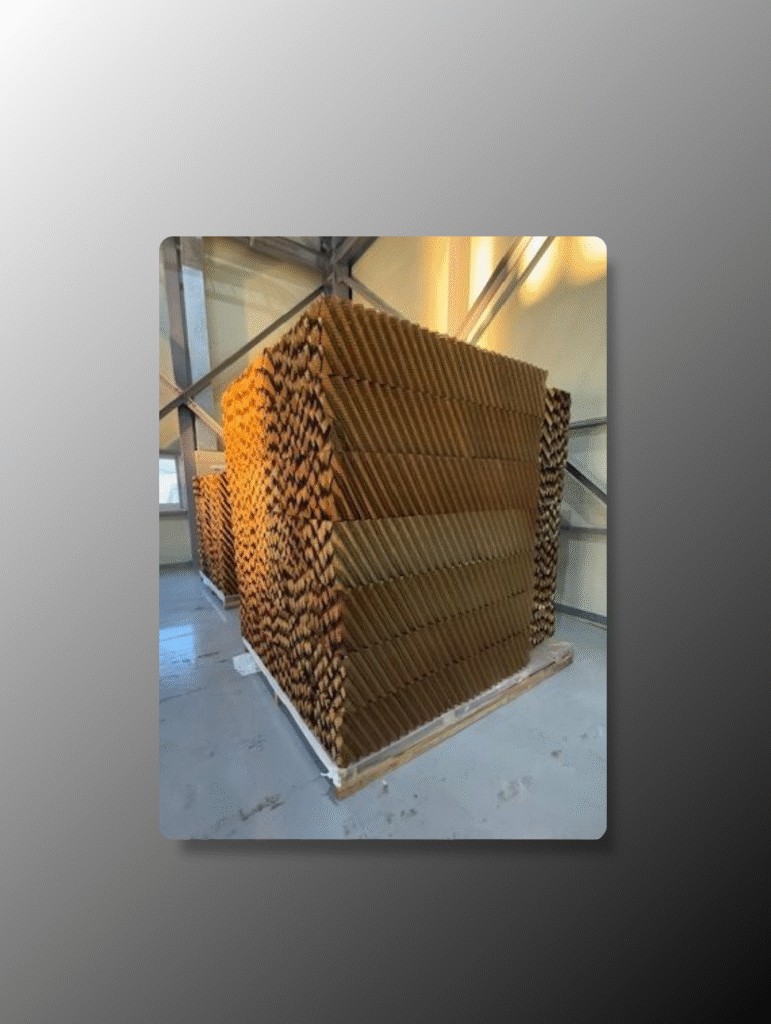

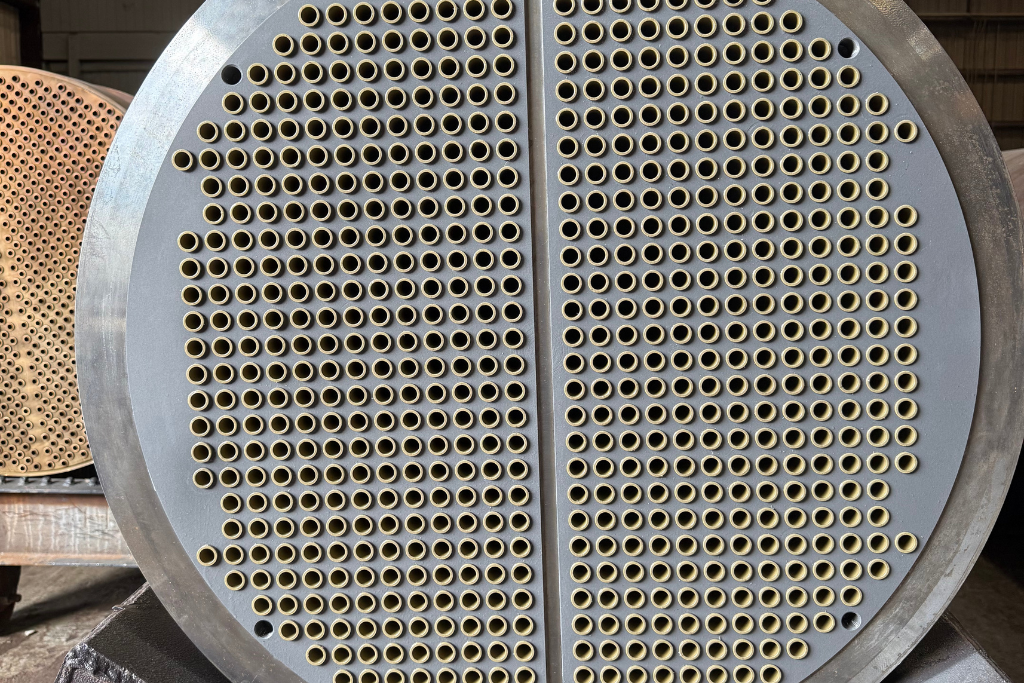

| Equipment | Shell-and-tube exchanger using high-chloride seawater with biofouling and scaling issues |

| Challenge | Marine biofilm and scale would quickly foul tube interiors, reducing flow and heat transfer. Bundle required frequent mechanical cleanings |

| Solution | Curran 5100 hydrophobic film minimized fouling adhesion |

| Results |

|

Proven solutions for fouling-resistant heat transfer equipment

Super Major Texas Refinery.

| Equipment | Hydrotreater preheat exchangers exposed to extreme conditions |

| Challenge | Severe fouling required constant cleaning |

| Solution | Curran 5100 application to exchanger components and piping |

Chemical Processing Facility

| Equipment | Steel tanks with interior lining degradation |

| Challenge | Erosion and frequent relining caused by agressive chemicals |

| Solution | Curran 5100 application provided a chemical-resistant barrier |

Marine Application

| Equipment | Shell-and-tube exchanger exposed to seawater fouling. |

| Challenge | Heavy marine biofouling required constant cleaning |

| Solution | Curran 5100’s hydrophobic film minimized fouling adhesion |

Curran International: 35+ years partnering with clients to solve critical fouling and corrosion cooling water challenges through advanced coating technology

Discuss your heat exchanger fouling challenges and operating conditions with a Curran team member.

Curraan 5100 is specified based on operating temperatures, substrate/metallurgy, service media, and equipment type.

Coordinate scheduling to ensure your unit is returned to site on time, whether it's shipping from your facility or directly from a fabricator.

Expert application with full QC documentation provided. Third-party inspection available upon request. Unit is returned to site ready for installation.

01

No – in fact it often improves overall heat transfer performance over the service life. The coating is extremely thin (10–15 microns), adding virtually no insulating layer. By preventing fouling, Curran 5100™ keeps surfaces much cleaner than uncoated surfaces, maintaining higher heat transfer coefficients for longer. In condensing applications, the hydrophobic surface enables dropwise condensation with heat transfer coefficients 5×–7× higher than traditional filmwise condensation.

02

Curran 5100 is designed for multi-year service in industrial environments. In real cases, the coating has remained effective for 5–7+ years.

For example, refinery exchangers coated with 5100 have operated for 2+ years with minimal fouling, whereas previously they required cleaning every few months.

03

Yes. Curran 5100 carries an NSF/ANSI 51 certification for Food Zone use, meaning it has been tested and approved as a safe coating for surfaces that encounter food for human consumption (all types of food) up to 400°F. The cured coating contains no heavy metals, BPA, or PTFE, making it suitable for food processing equipment and pharmaceutical systems where purity is critical.

04

Curran 5100 adheres well to most metals used in industry, including carbon steel, stainless steel, copper alloys (brass, copper-nickel), cast iron, and even glass or ceramic surfaces. The key is proper surface preparation – usually a near-white metal grit blast for steel surfaces.

Please enter your name and email.

We’ll email the data sheets shortly.